Trench cutting apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

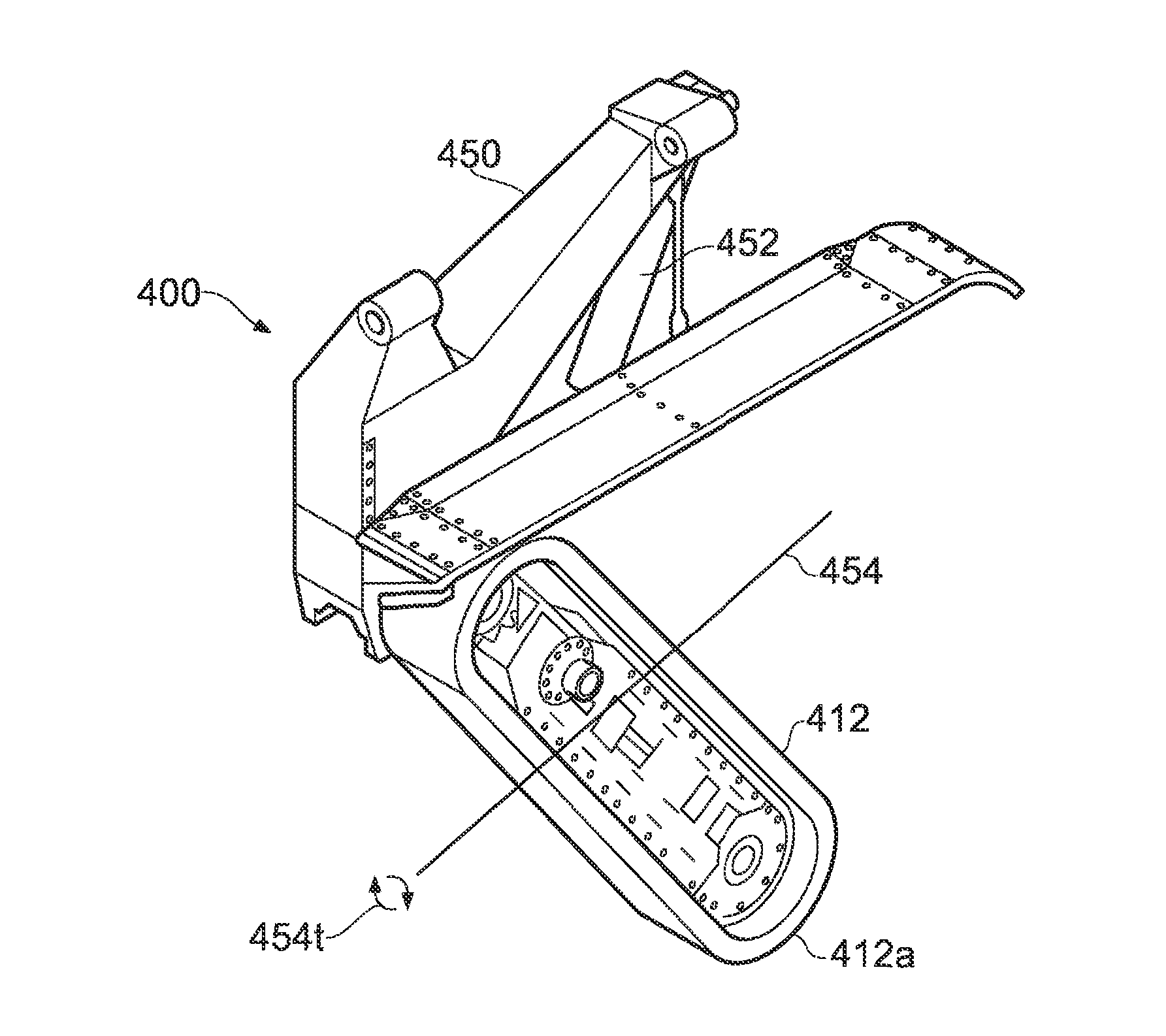

Image

Examples

Embodiment Construction

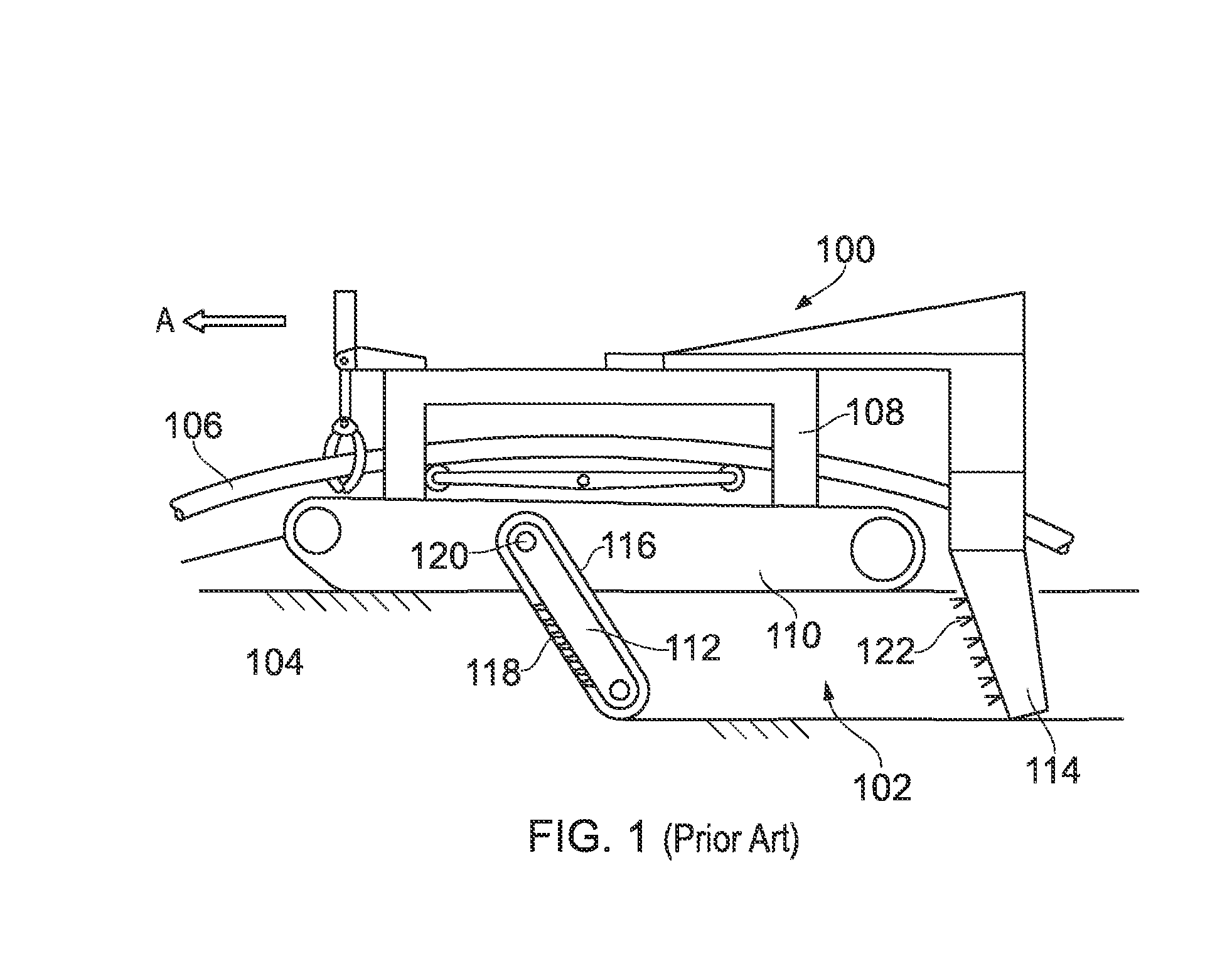

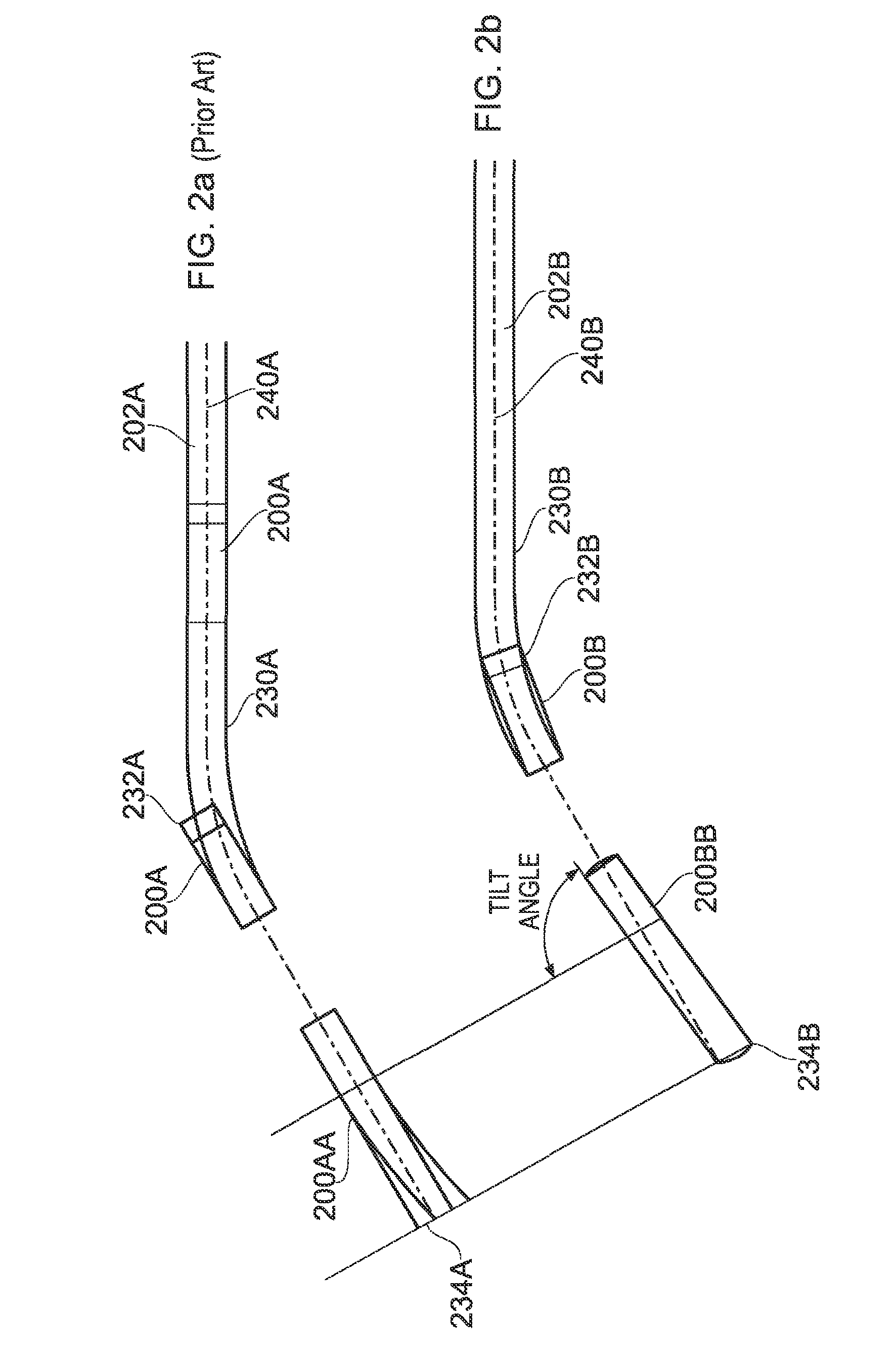

[0031]Referring now to the drawings, the present invention addresses the problem of the formation of undercuts in a trench side wall in curved portions of a trench when the trench is formed using apparatus of the prior art. Undercuts are formed with prior art apparatus in the outer trench wall, that is, the wall in a curved section of trench having a greater radius of curvature than an opposed inner trench wall.

[0032]FIG. 1 shows on example of a prior art trenching apparatus 100, in this particular case configured for forming a trench 102 in the seabed 104 and simultaneously burying a pipeline 106 in the trench 102. For the avoidance of doubt, the apparatus according to the present invention may usefully be equipped with means both for trench forming and for simultaneous burying of a pipeline, but pipe burying means are not per se an essential feature of the apparatus of the invention. The prior art apparatus 100 includes a main body 108 and ground contacting conveying means 110 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com