Mass velocity sensor device and method for remote monitoring and visual verification of fluid velocity

a mass velocity sensor and fluid velocity technology, applied in liquid/fluent solid measurement, volume metering, instruments, etc., can solve the problems of low flow range sensitivity, achieve easy maintenance and adjustment, improve accuracy, and reduce resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

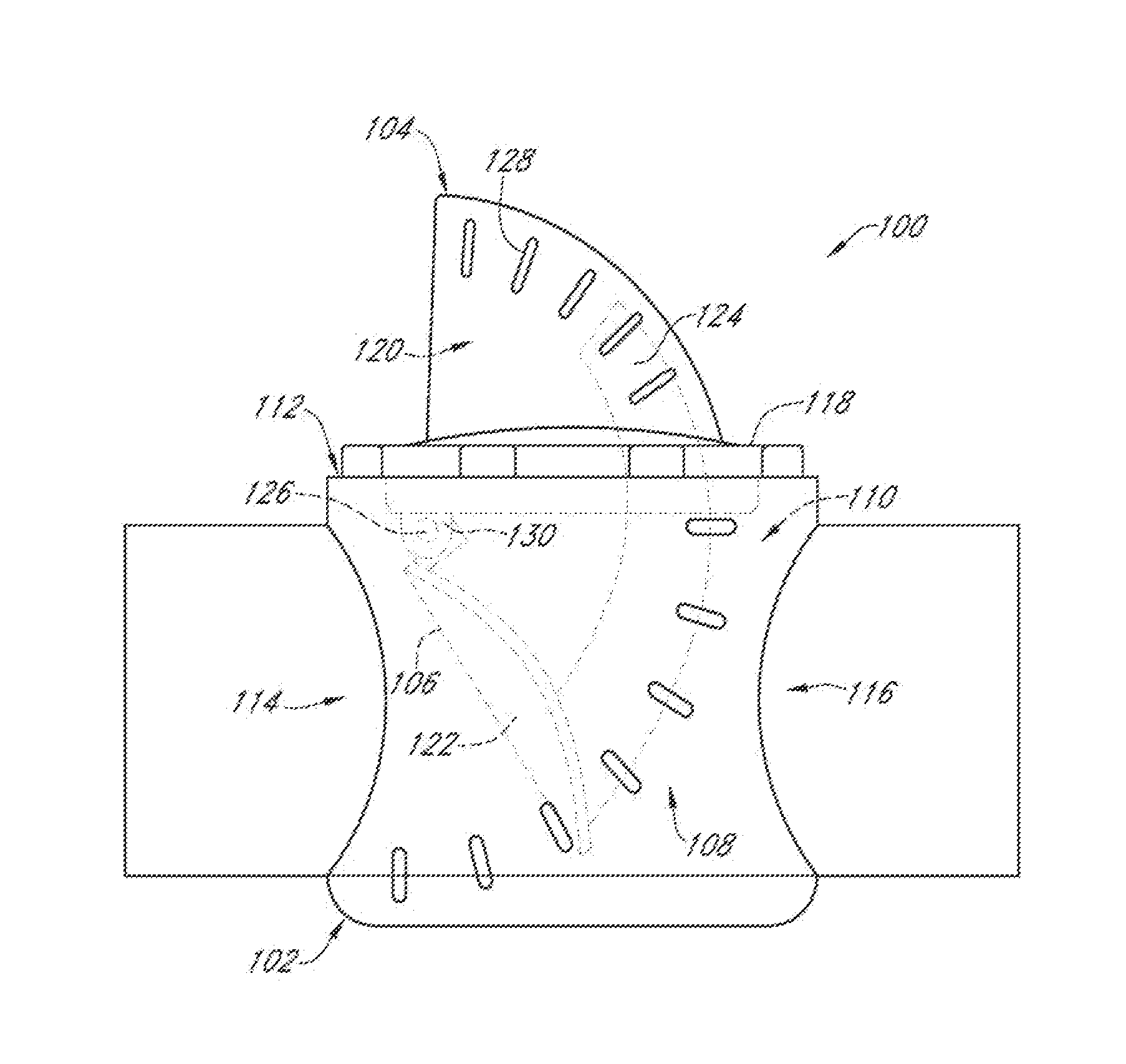

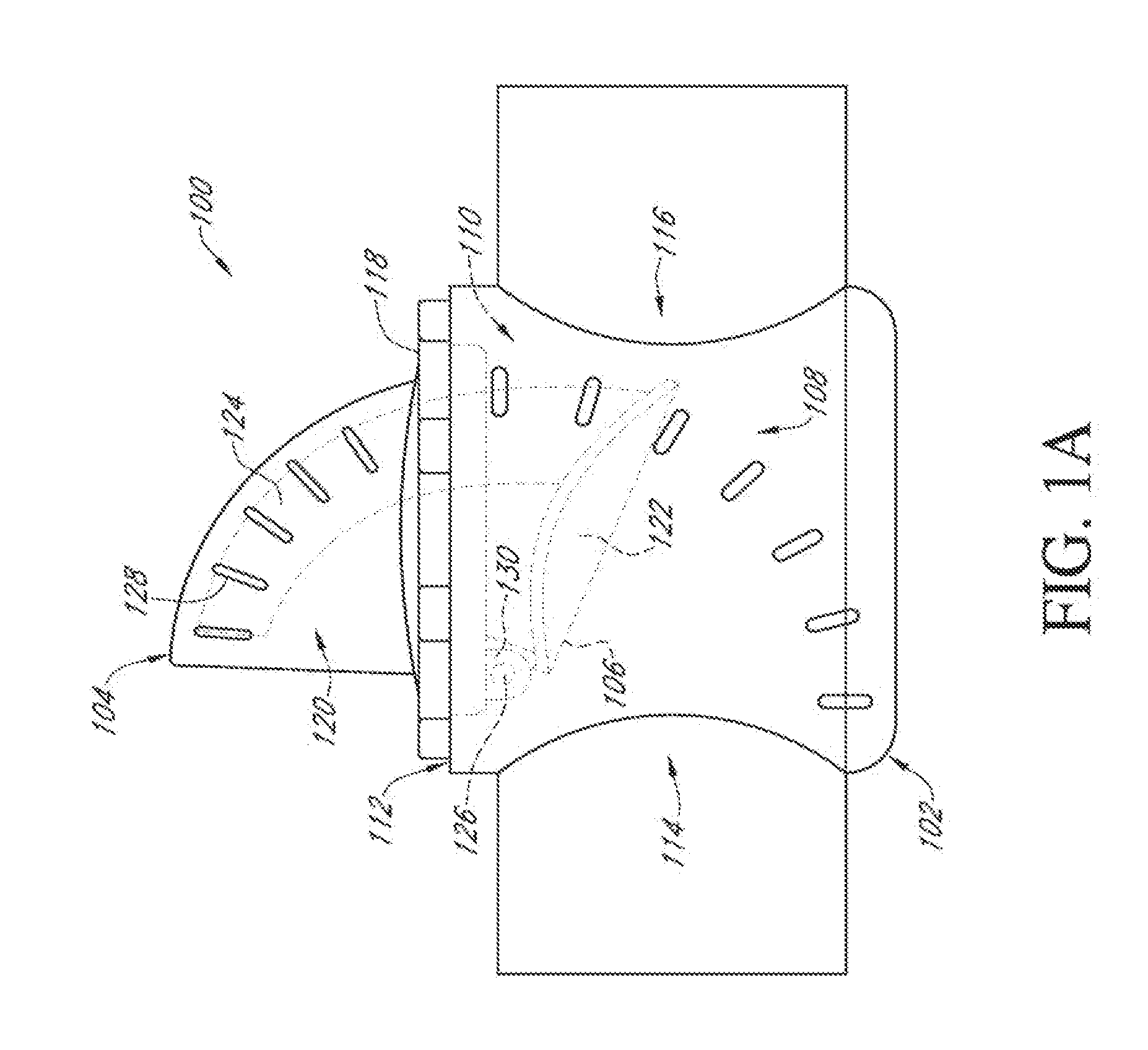

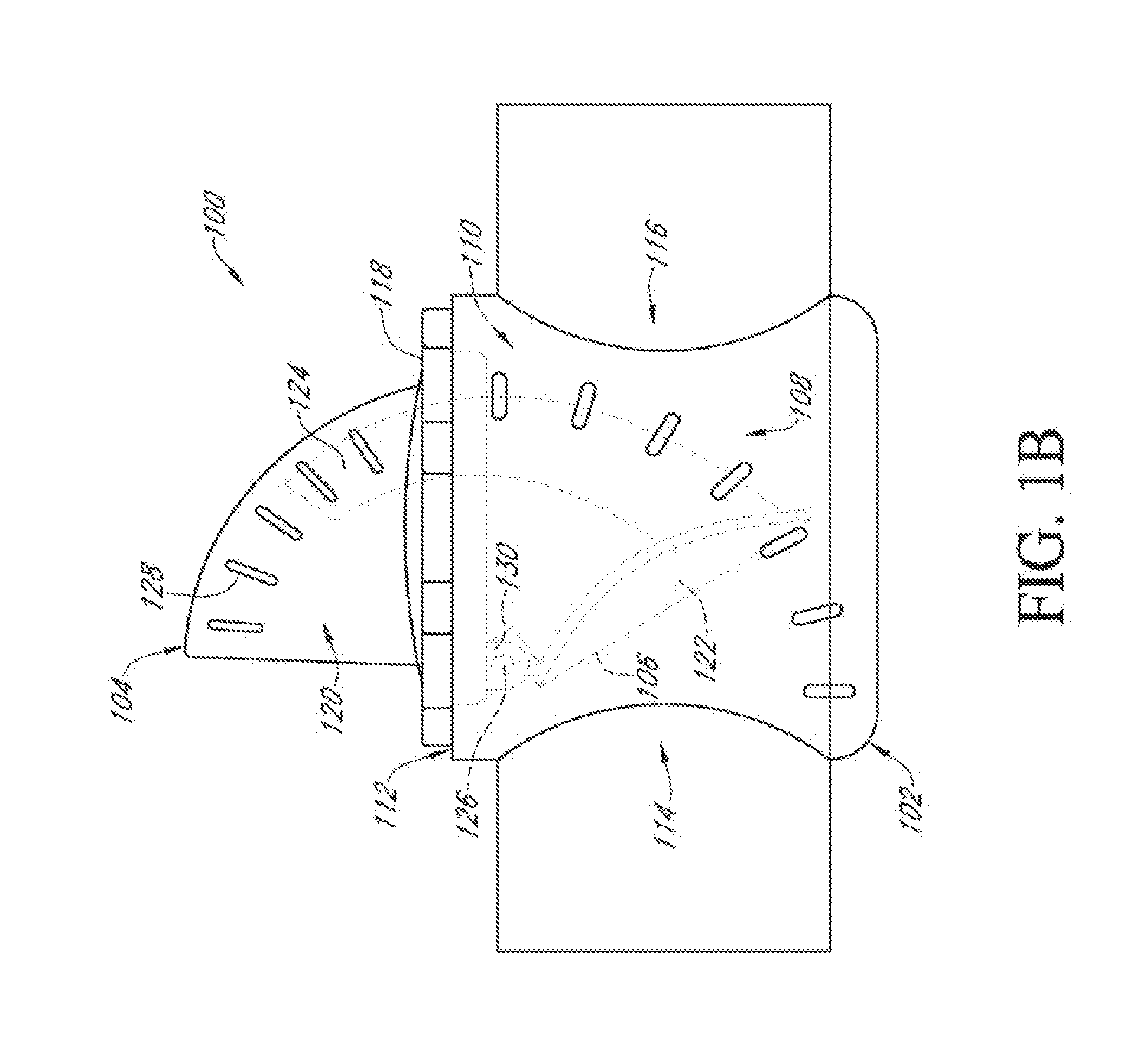

[0022]Reference will now be made to the drawings wherein like numerals refer to like parts throughout. FIGS. 1A and 1B illustrate a flow sensor assembly 100 according to one embodiment of the present invention. The flow sensor assembly 100 generally comprises a mounting body 102, a protruding lid 104 extending upwardly above the mounting body 102, and a pivotable obstruction member 106 disposed inside the mounting body 102. The mounting body 102 is configured with sidewalls 108 defining a receptacle 110 having an upper opening 112, and fluid inlet 114 and outlet 116 ports disposed on opposing sides of the receptacle 110. The mounting body 102 can be positioned in a flow stream, such as fitted to a conventional pipe or channel segment using fittings and methods known in the art. The protruding lid 104 has a base rim 118 and a receiver pocket 120 extending upwardly from the base rim 118. The base rim 118 is sealingly engaged with the mounting body 102 using screw type fasteners or oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com