Afterburner and aircraft engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention has been made with a result of an analysis using the below-described three-dimensional steady viscosity CFD (Computational Fluid Dynamics) taken into consideration.

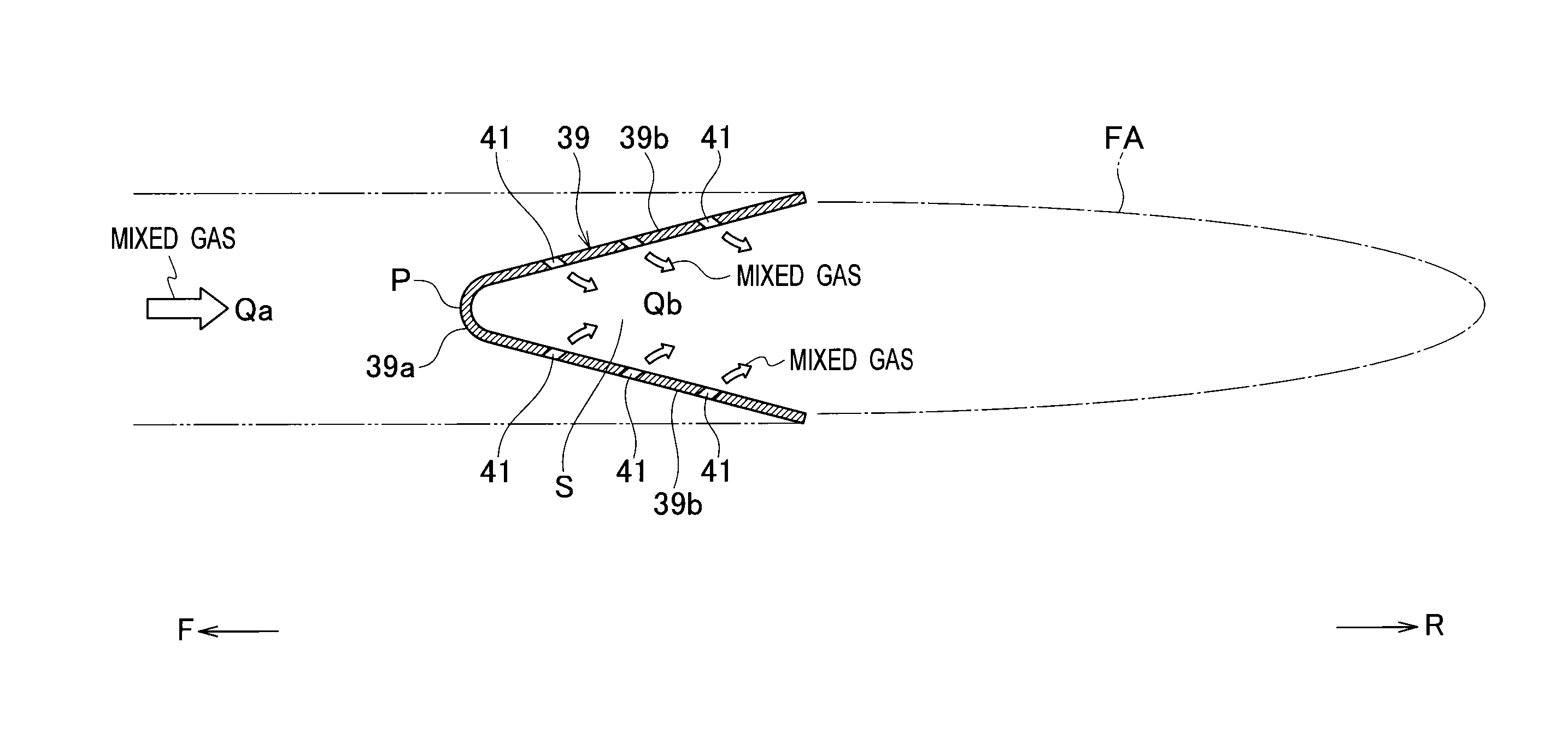

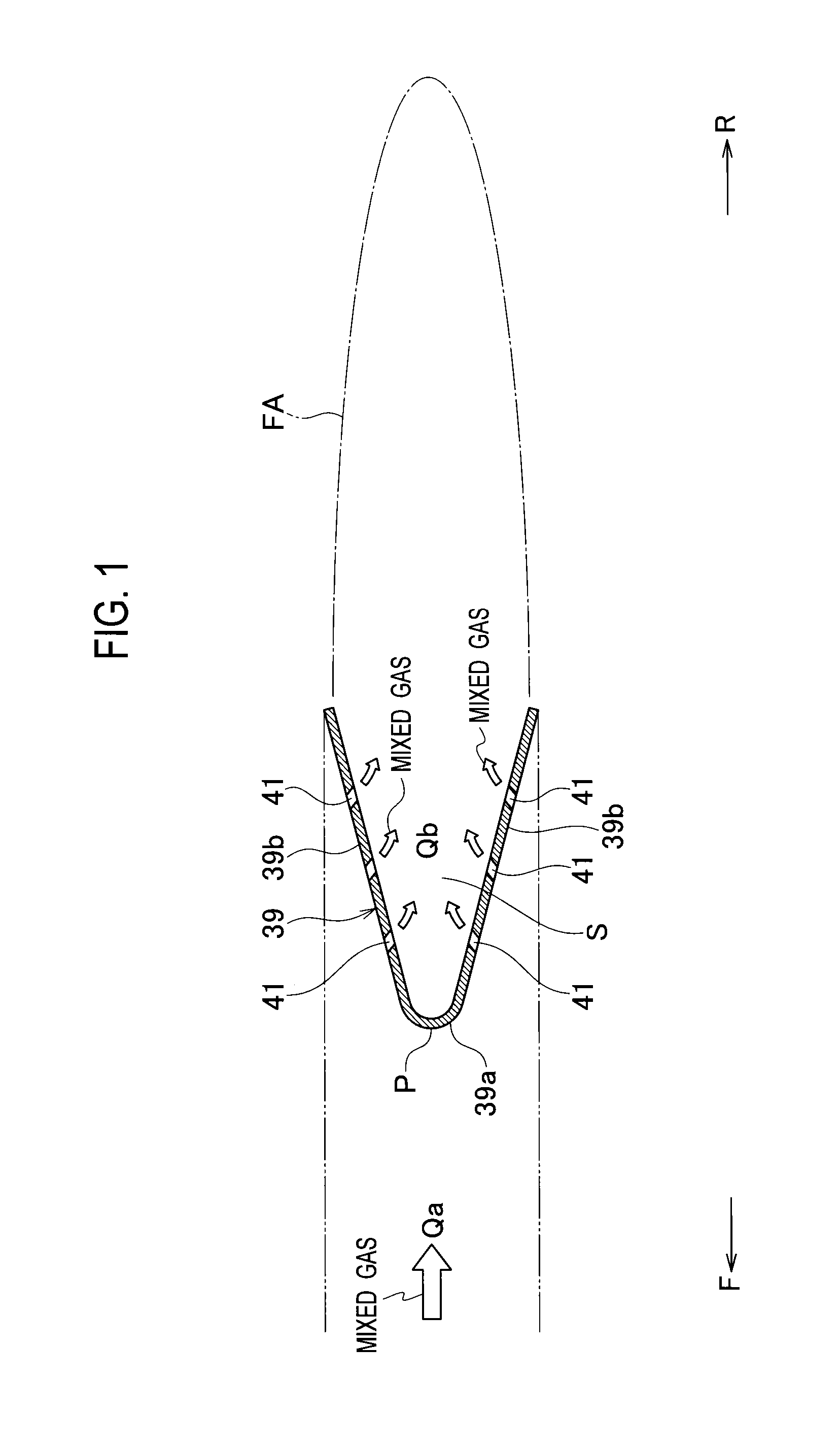

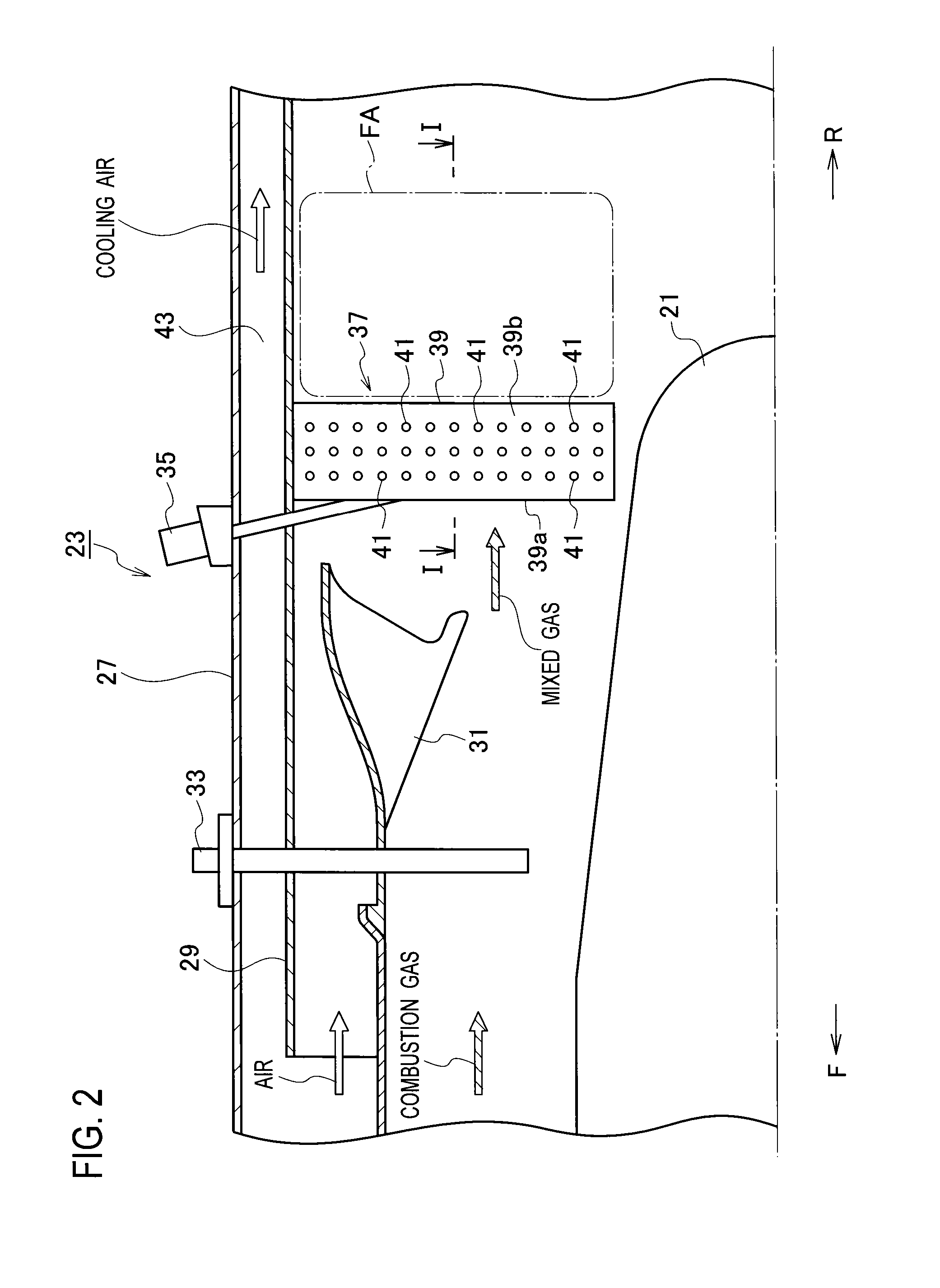

[0023]This analysis used an assumed gutter having a V-shaped cross-sectional shape which was opened to a downstream side of the gutter and including multiple through-holes formed only in its two side surface sections. The analysis found a relationship between a ratio Qb / Qa of mass flow rates of mixed gases (a predetermined ratio of mass flow rates in an aircraft engine in operation) and a pressure coefficient on the downstream side of the flame stabilizer. In this respect, Qa denotes amass flow rate of a mixed gas flowing toward the gutter in the aircraft engine in operation, and Qb denotes a mass flow rate of a mixed gas introduced into the gutter through the multiple through-holes in the gutter. FIG. 6 shows the result of the analysis. As shown in the graph, it was learned that as the ratio Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com