Vacuum insulation cup lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

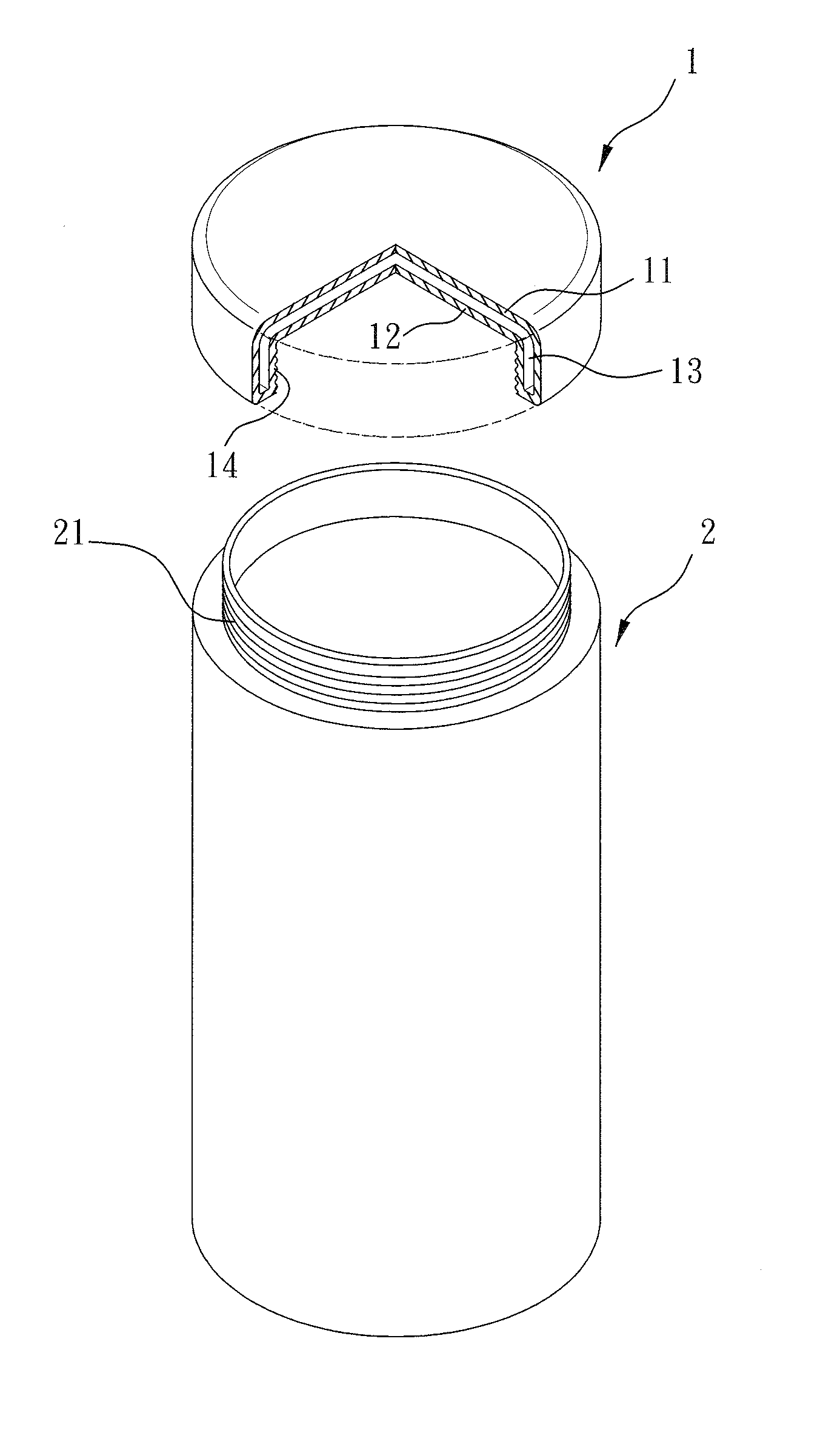

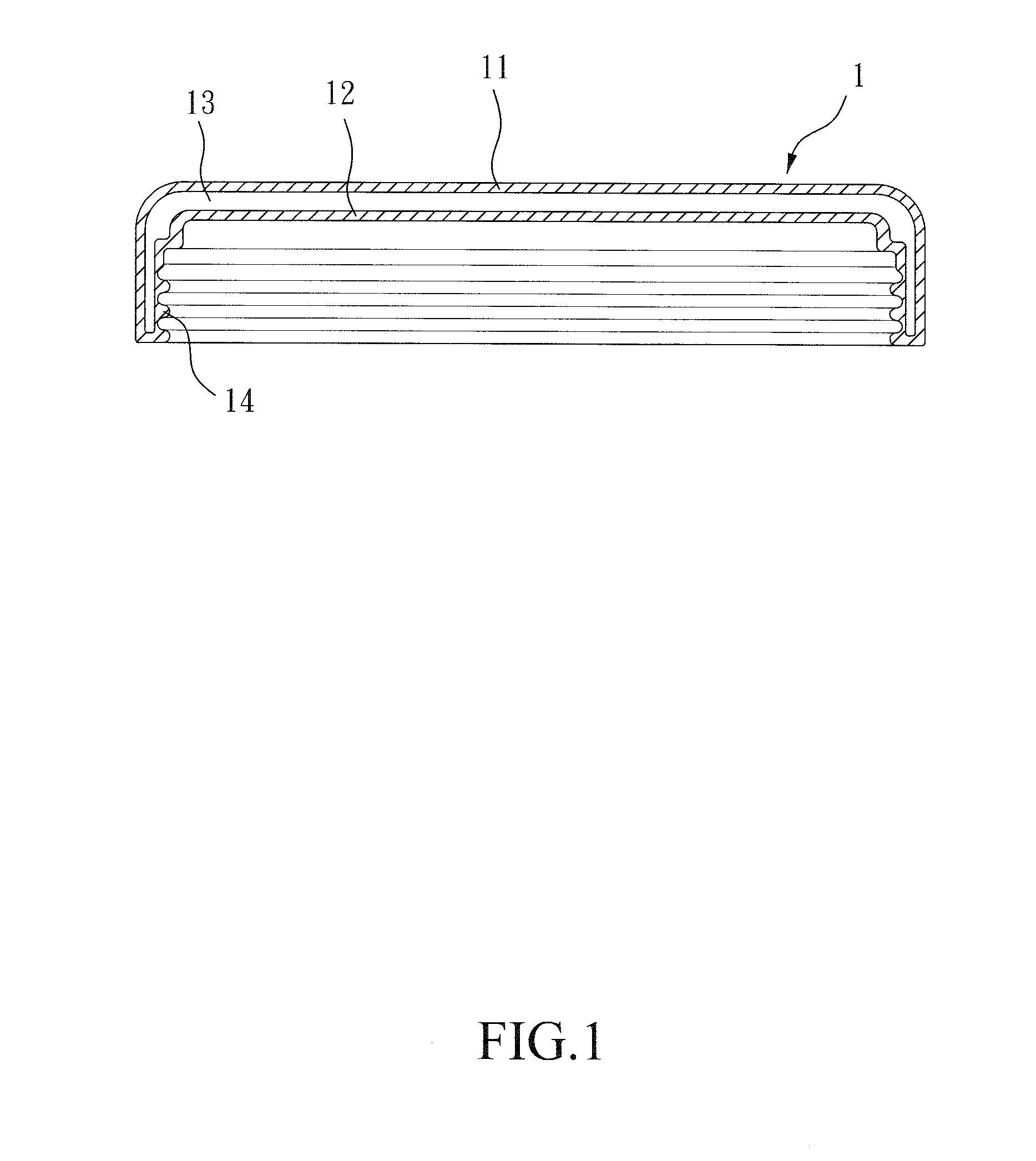

[0010]Referring to FIG. 1, which shows a vacuum insulation cup lid of a preferred embodiment of the present invention, one end face and a side wall of the circumference of a cup lid 1 are integrally formed into a outer side wall 11 and inner side wall 12, where a heat-insulated space 13 is formed between the outer side wall 11 and inner side wall 12. In addition, an internal thread 14 is formed on an inner diameter of the inner side wall 12. the heat-insulated space 13 is a sealed space, evacuated by drawing air therefrom completely upon the manufacturing of the cup lid, allowing no medium capable of conducting heat to exist between the outer side wall 11 and inner side wall 12.

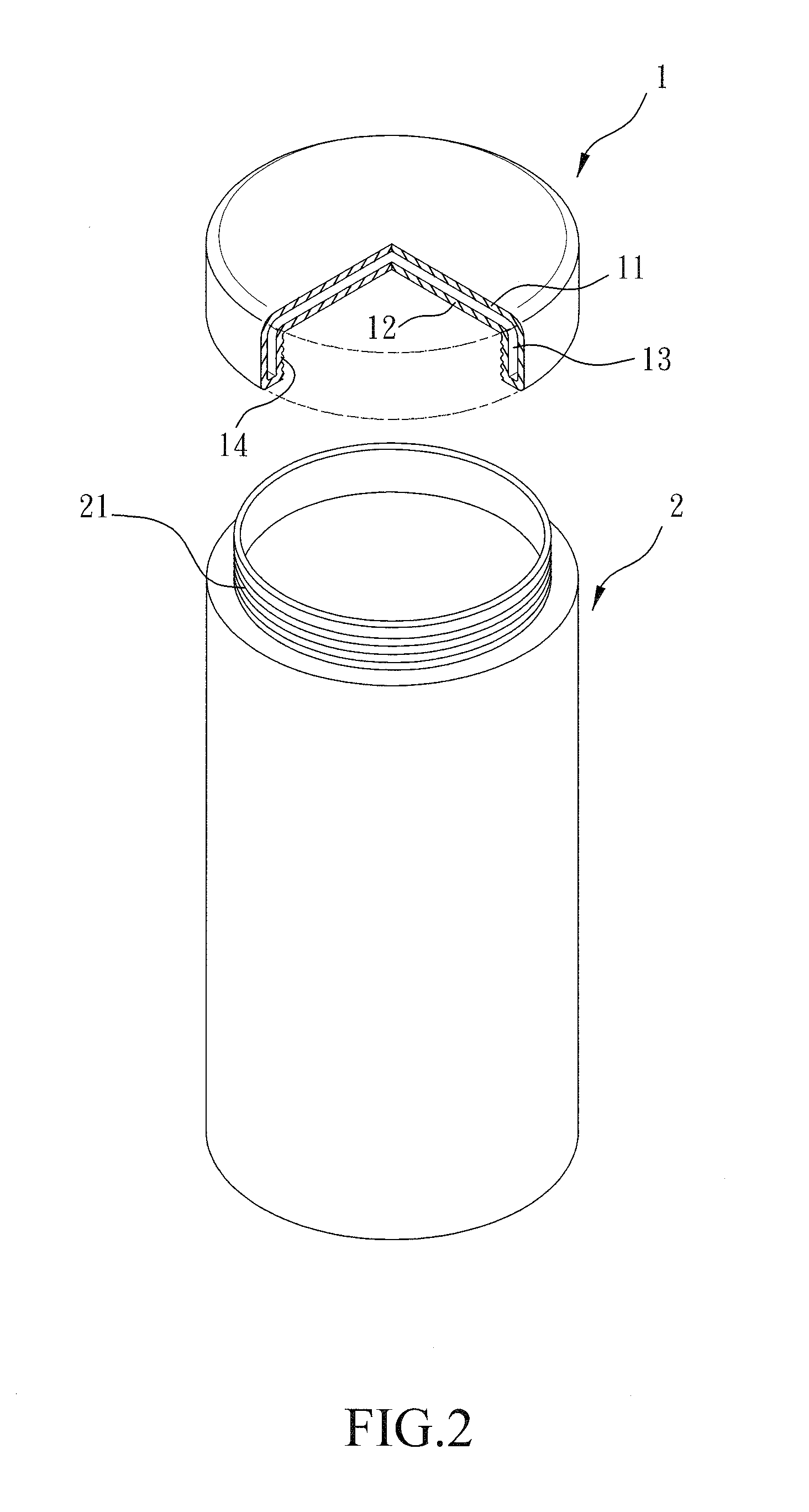

[0011]Referring to FIGS. 2 and 3, which show the combination of the cup lid 1 and a cup body 2 having a similar heat-insulated effect, the cup body 2 is a container allowing water, tea or liquid to be filled therein; it has an inner space extended downward to a certain depth, and an opening is formed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com