In-line vacuum lquid aspirator

a vacuum cleaner and liquid aspirator technology, applied in the field of vacuum cleaners, can solve the problems of limited one-time liquid collection capacity, heavy user handling and maneuverability, and easy damage to the electrical and electronic parts of the vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following description presents several preferred embodiments of the present invention in sufficient detail such that those skilled in the art can make and use the invention.

[0020]Before describing in detail embodiments that are in accordance with the present invention, it should be noted that all of the figures are drawn for ease of explanation of the basic teachings of the present invention only. The extension of the figures with respect to the number, position, relationship and dimension of the parts of the preferred embodiment will be within the skill of the art after the following teachings of the present invention have been read and understood. Further, the exact dimensions and dimensional proportions to conform to specific force, weight, strength and similar requirements will likewise be within the skill of the art after the following teachings of the present invention have been read and understood.

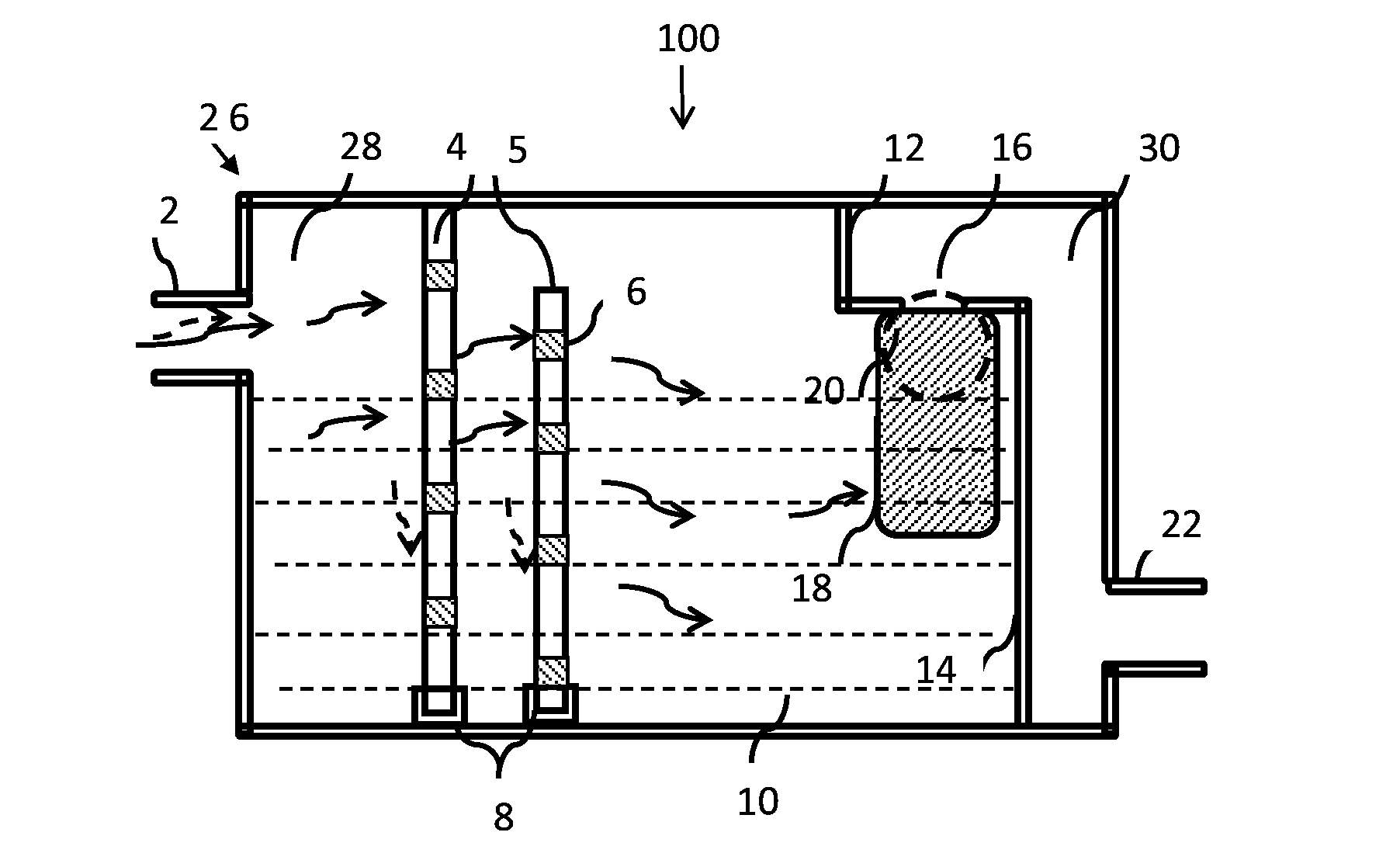

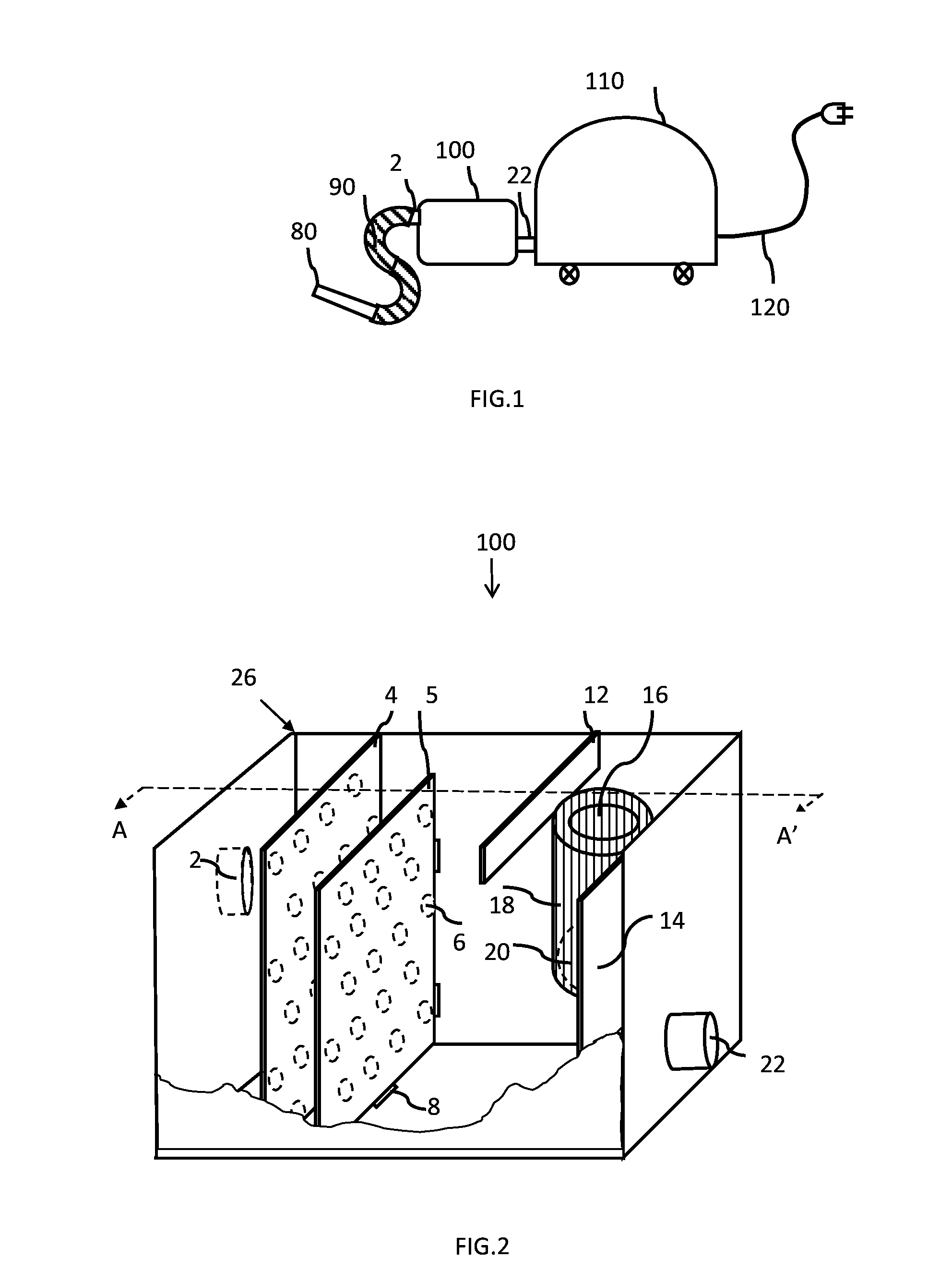

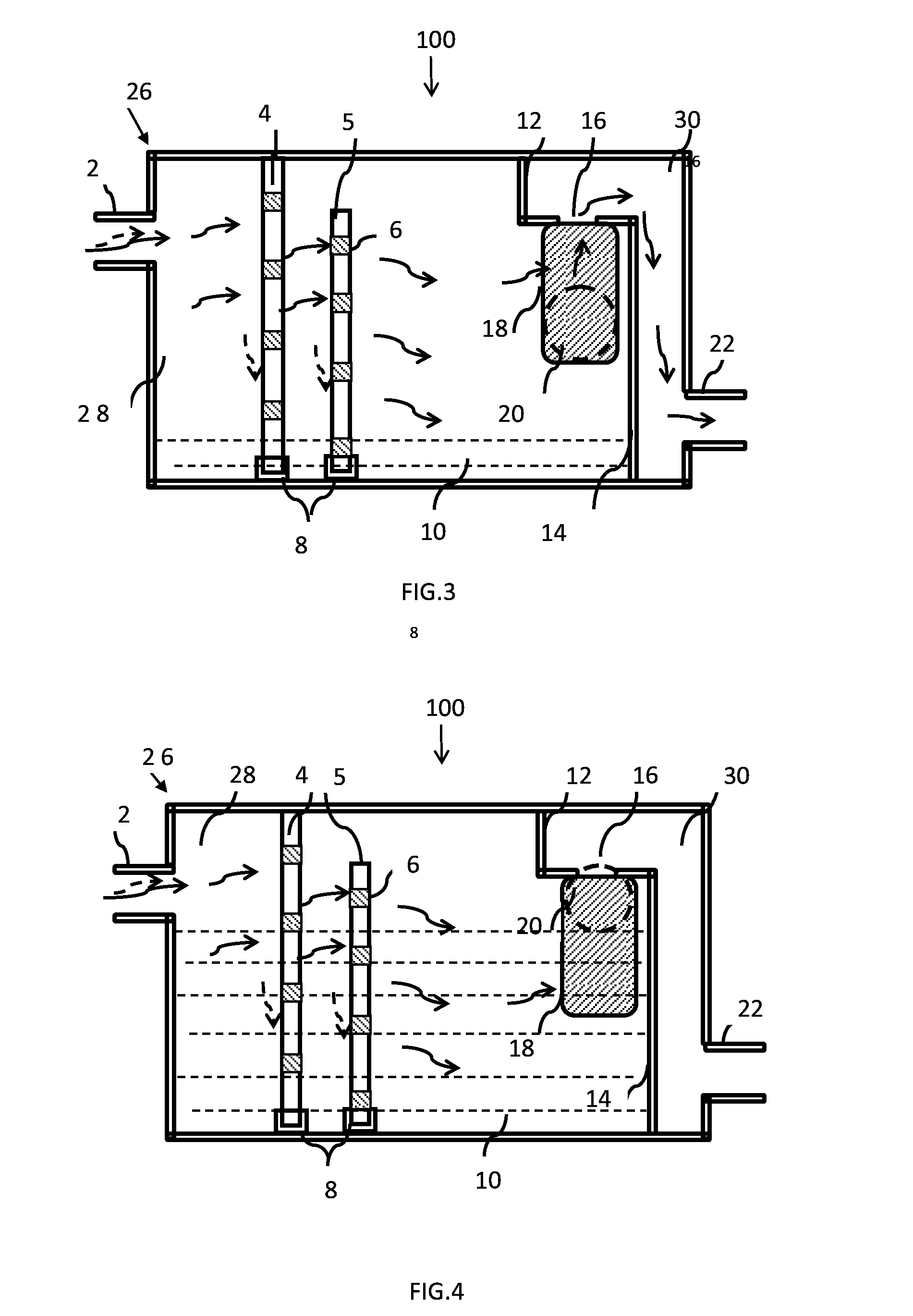

[0021]FIG. 1 is a representation of a possible configuration of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com