Method and apparatus for curing co2 composite material objects at near ambient temperature and pressure

a composite material and ambient temperature technology, applied in the field of materials processing, can solve the problems of needlessly expended time effort and money, wet mix will either have to be discarded,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

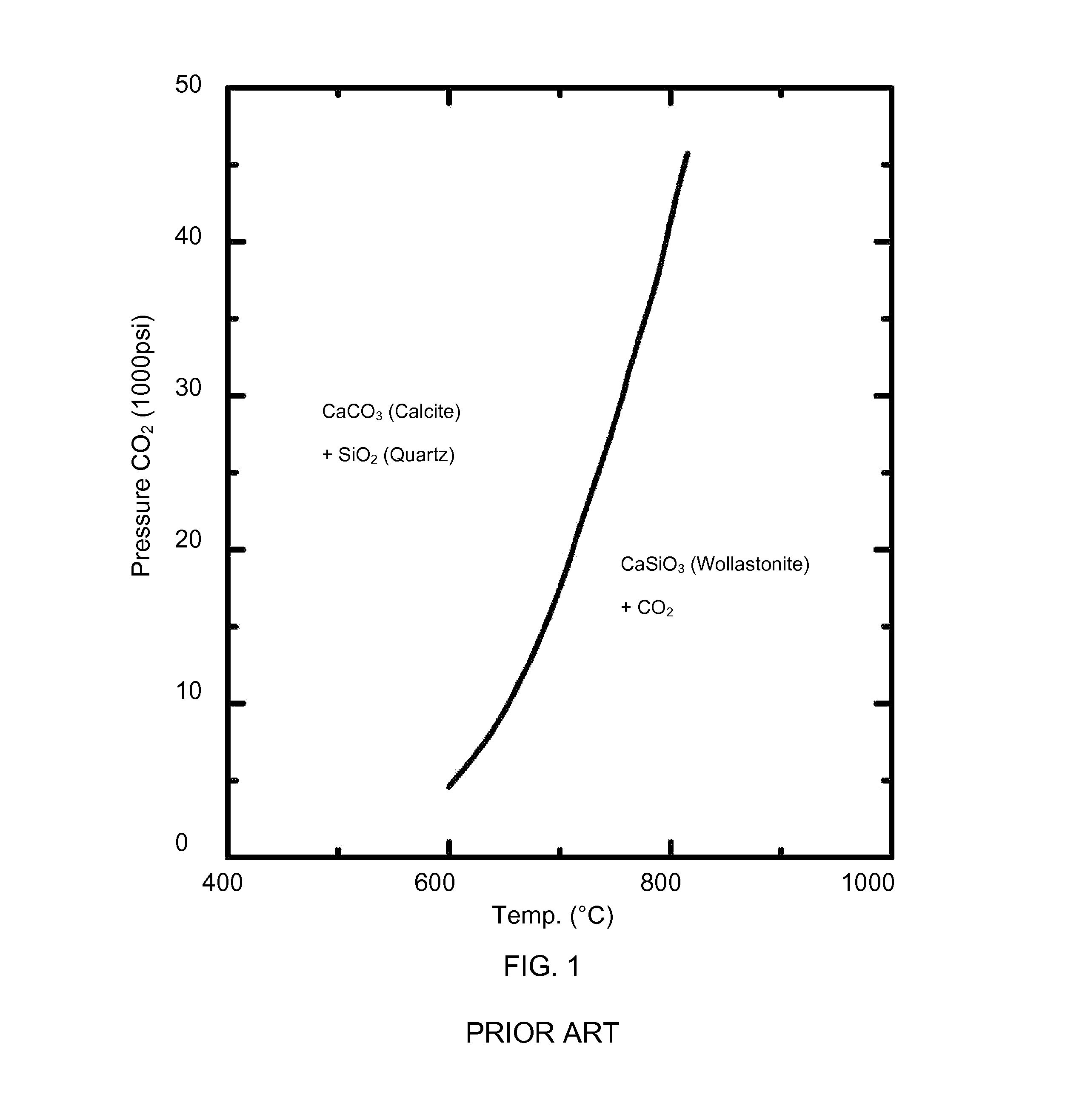

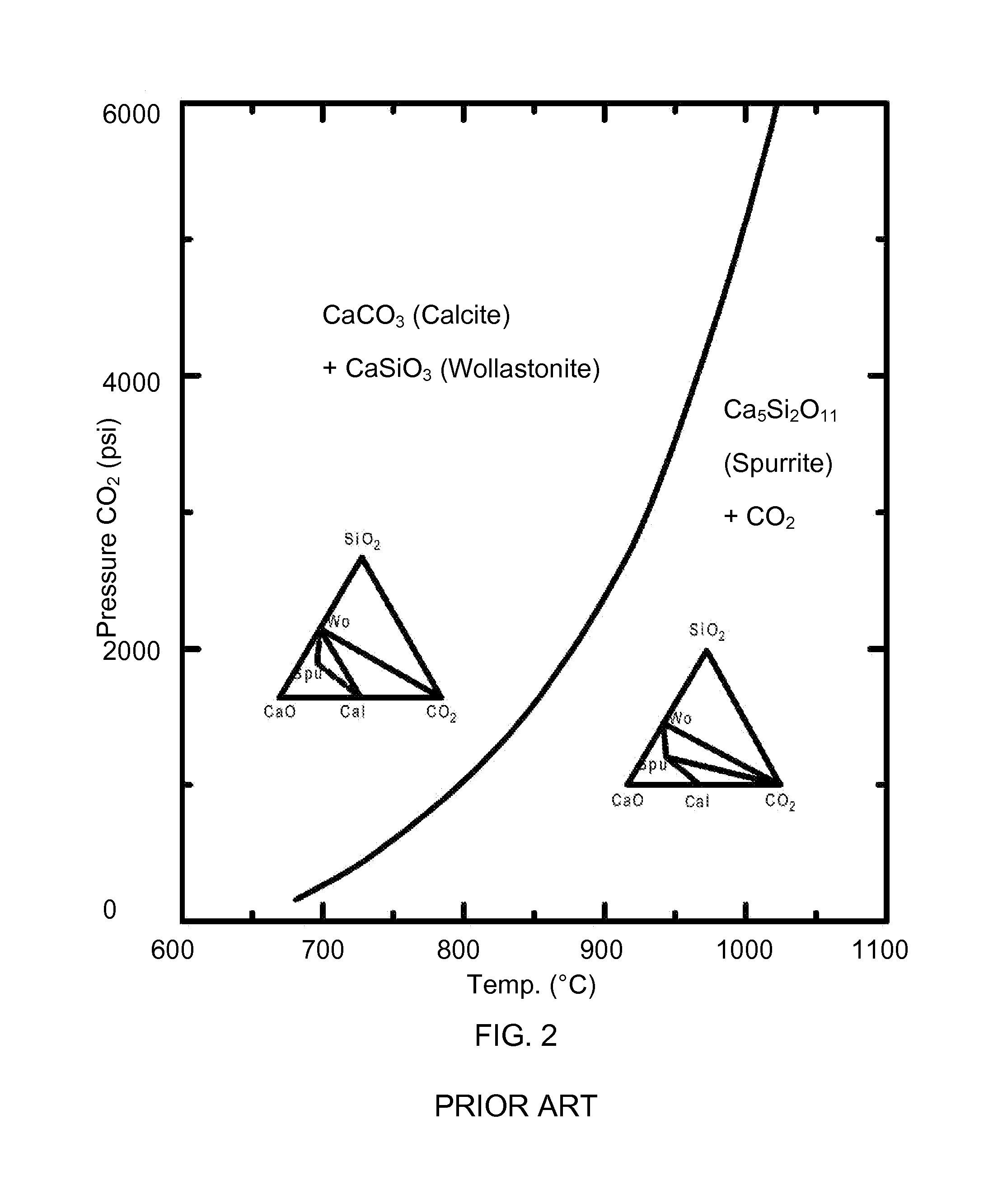

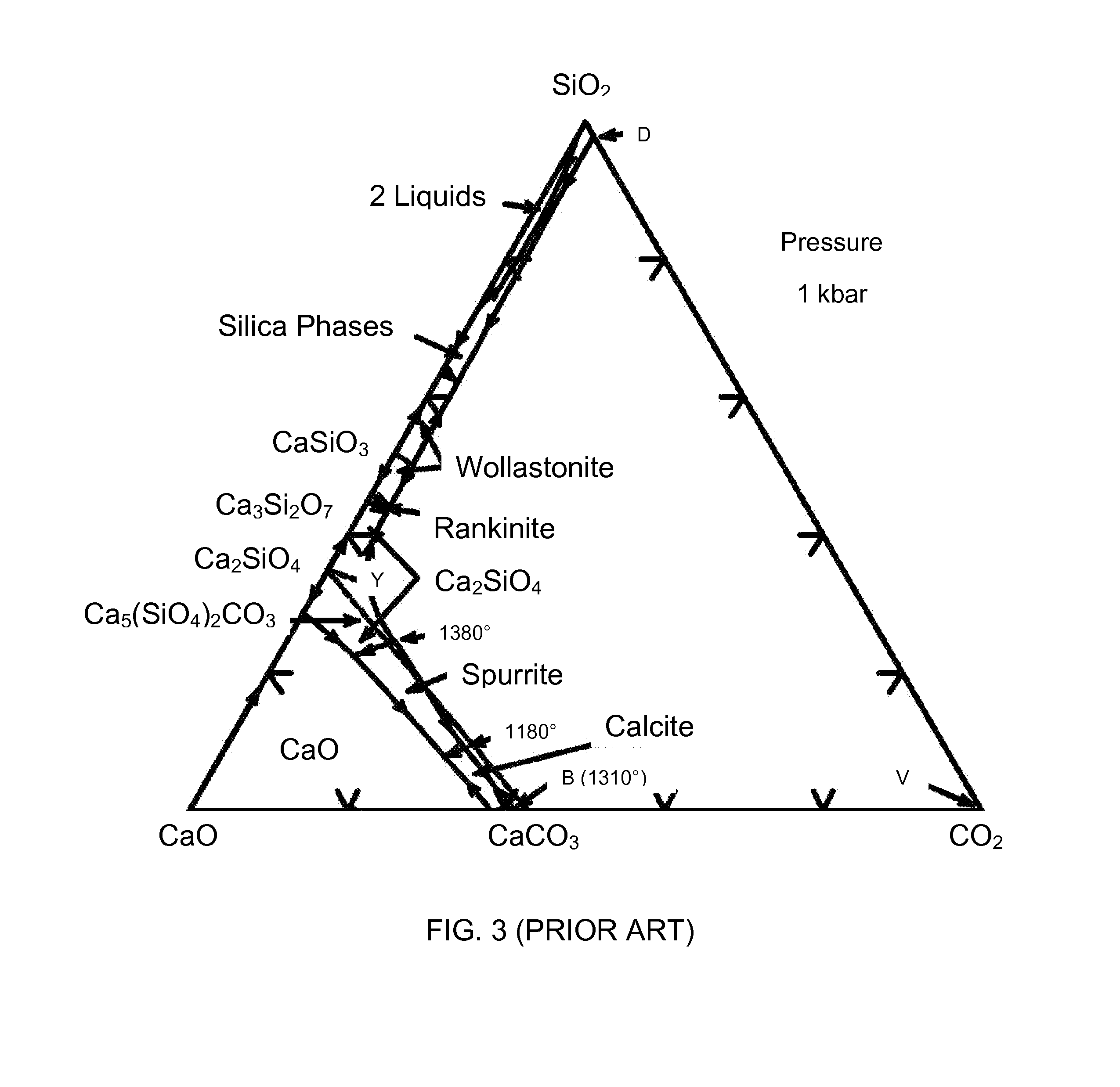

Chemical Discussion

[0101]This invention provides apparatus and methods used to manufacture novel composite materials that are cured predominantly by a CO2 consumption reaction. The materials exhibit useful properties and can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production with minimal environmental impact. The precursor materials include inexpensive and abundant calcium silicate rich materials, fine particles and coarse particles. The calcium silicate rich materials may be comprised of ground Wollastonite. The fine and coarse particles may be comprised of ground limestone or other calcium carbonate based materials, ground quartz or other SiO2 based materials, sand and crushed rock. The fine and coarse particles may also be comprised of crushed minerals such as granite, mica and feldspar. Other process components include water and CO2. Various additives can be used to modify and fine-tune the physical appearance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com