A kind of quick-drying quick-flammable sealing glue and its preparation method and application

A technology of sealing glue and drier, applied in the direction of adhesive types, non-polymer adhesive additives, starch adhesives, etc. The effect of increasing strength, not easy to return to moisture, and improving the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A quick-drying and quick-burning sealing glue of the present invention, the raw materials of the quick-drying and quick-burning sealing glue include: 35g of cornstarch, 45g of hydrogen peroxide, 6g of aluminum sulfate, 10g of sodium bicarbonate, and 3g of gypsum.

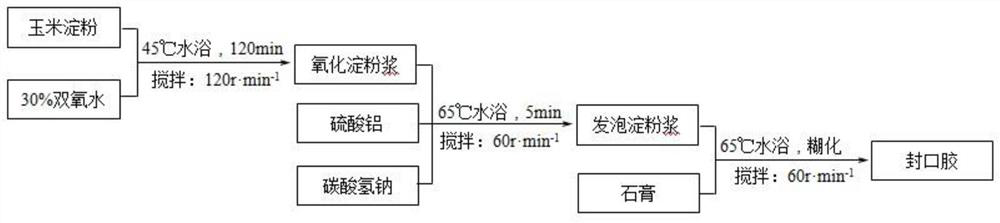

[0036] A preparation method of the quick-drying and quick-burning type sealant of this embodiment, the schematic diagram of its technological process is as follows figure 1 shown, including the following steps:

[0037] (1) Disperse 35g of cornstarch in 45g of 30% hydrogen peroxide to form a suspension, carry out oxidation treatment, the oxidation treatment is carried out under the condition of heating in a water bath, the control temperature is 45°C, and the time is 120min, during the oxidation treatment process Supplemented by stirring, the stirring rate is 120r·min -1 , obtain suspension slurry;

[0038] (2) Raise the temperature of the water bath to 65°C, and control the stirring rate at 60r·min -1, ad...

Embodiment 2

[0041] A quick-drying and quick-burning sealing glue of the present invention, the raw materials of the quick-drying and quick-burning sealing glue include: 33g of potato starch, 48g of hydrogen peroxide, 7g of aluminum sulfate, 10g of sodium bicarbonate, and 5g of gypsum.

[0042] A preparation method of the quick-drying quick-burning type sealant of the present embodiment, comprises the following steps:

[0043] (1) Disperse 33g of potato starch in 48g of mass concentration of 30% hydrogen peroxide to form a suspension, carry out oxidation treatment, the oxidation treatment is carried out under water bath heating conditions, the control temperature is 45 ℃, and the time is 90min, during the oxidation treatment process Supplemented by stirring, the stirring rate is 150r·min -1 , obtain suspension slurry;

[0044] (2) Raise the temperature of the water bath to 60°C, and control the stirring rate at 90r·min -1 , add 7g of aluminum sulfate and 10g of sodium bicarbonate to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com