Solar energy collectors and methods for solar energy systems

a solar energy system and solar collector technology, applied in solar heat collector details, lighting and heating apparatus, hybrid energy generation, etc., can solve the problems of high operating cost, limited heat pump, and insufficient ambient air heating of heat pump,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

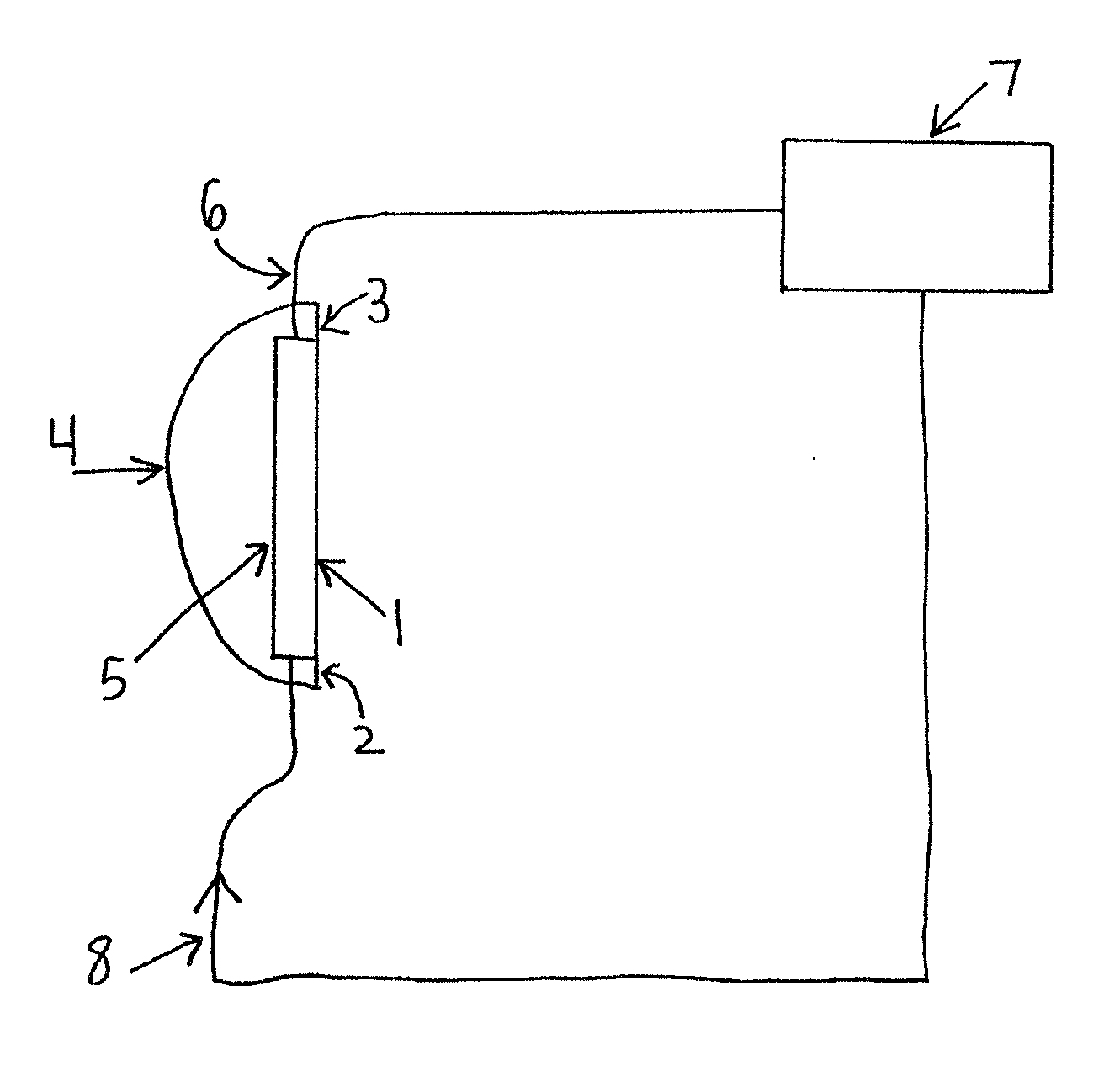

example 1

[0044]A static analysis of the heat required to raise conventional non-porous flat plate collectors to increase the temperature of the flat plate, compared to an example of a porous metal absorber plate collector of the present invention is a useful illustration of some of the benefits of the porous absorber plate collector of the present invention. Example calculations for energy (heat) required to raise the temperature by 100 degrees Fahrenheit for 2 examples of the present invention porous absorber plate collector plate compared to conventional non-porous flat collector plates are shown in Table 1:

TABLE 1HeatVolume(Energy)LengthWidthdepth(cubicDensityrequiredFlat plate Type(ft)(ft)(ft)feet)(lbs / ft3)(BTU)non-porous copper310.040.12555613(conventional)porous copper (present310.040.1231.234invention example)non-porous aluminum310.040.12169454porous aluminum (present310.040.1231.284invention example)

The static heat required is observed to be about 80 to 95% less for these examples of...

example 2

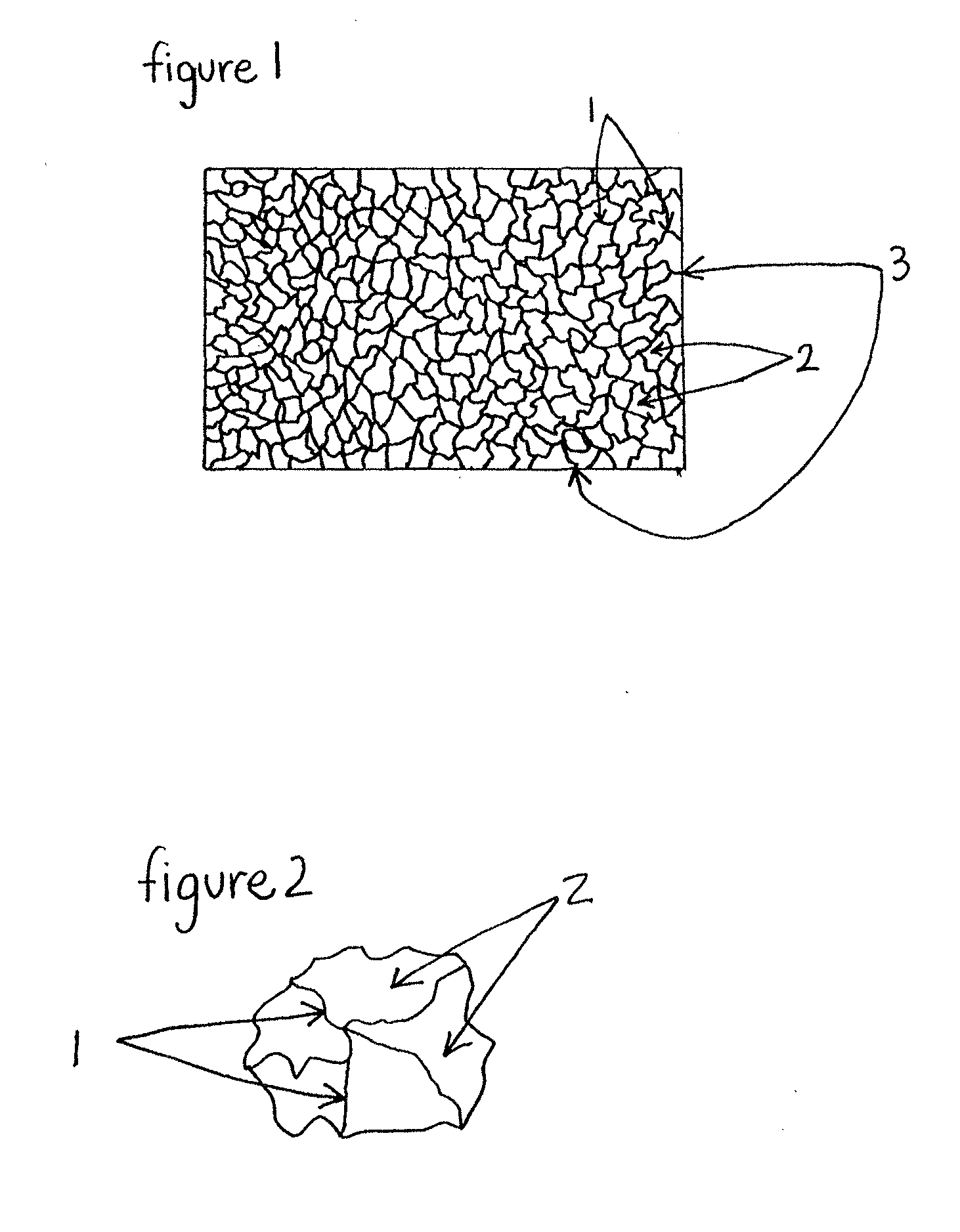

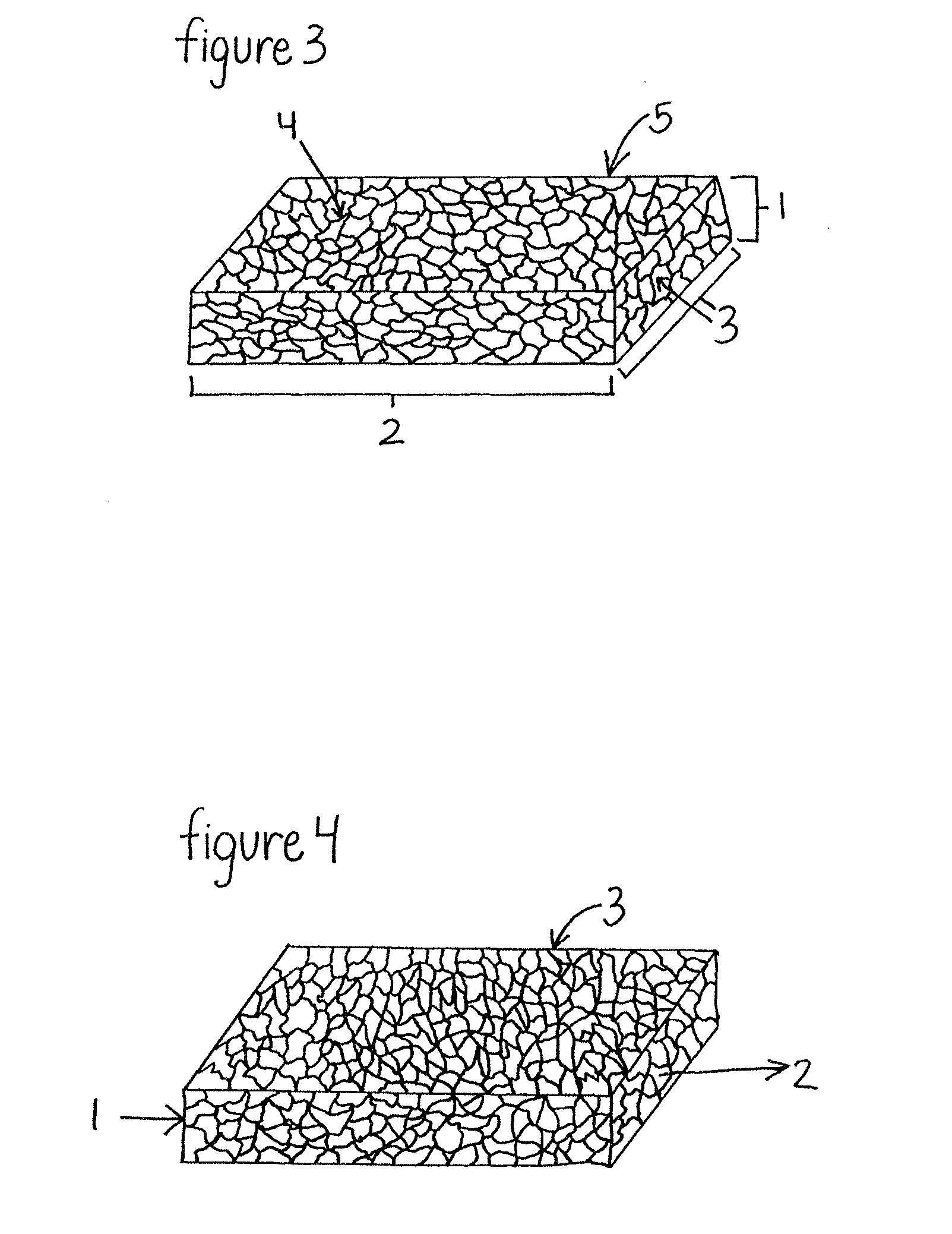

[0045]Two flat plate collectors were prepared. The collector embodiment of the present invention comprised of about 54 mm width by 57 mm long porous copper absorber plate, with a density of about 0.5 g / cc, a thickness of about 5 mm, and a porosity of about 97%. The porous copper absorber plate was spray painted with flat black high temperature paint. The absorber plate was placed inside an aluminum housing, insulated with fiberglass insulation to avoid contact with the aluminum walls, and sealed with a glass lid and silicone caulking A small hole was drilled to insert a thermocouple probe directly inside the copper absorber plate. An identical flat plate collector was prepared, except to use standard black anodized aluminum sheet metal (non-porous) of about 1 mm thick as the absorber plate, with about a 6 mm diameter copper tube inserted under the aluminum sheet absorber plate. A thermocouple probe was inserted into the inside wall of the copper tube. The collectors were placed in t...

example 3

[0046]An embodiment of the Fresnel lens duct concentrating-type solar collector was prepared using a duct of about 300 mm length and about 100 mm width, with 3 Fresnel flat-faced square lenses utilized side by side to form the face of the duct facing the sun. Each Fresnel lens was about 100 mm high by 100 mm wide, and about 2 mm thick, with a groove pitch of about 0.5 mm. A solar reflective film was formed in the shape of a parabola and inserted inside the duct, along the back face. A copper pipe with inside diameter of about 13 mm was painted with flat black high temperature spray paint, and inserted inside the duct in between the solar reflective film along the back face and the Fresnel lens front face. A thermocouple probe was inserted inside the copper pipe, to monitor temperature. The same flat-plate type embodiment of Example 1 with the porous copper absorber plate was used for comparison. The results over a 45 minute test with the collectors placed in the sun yielded the resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com