Method and apparatus for multiple recirculation and filtration cycles per dispense in a photoresist dispense system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

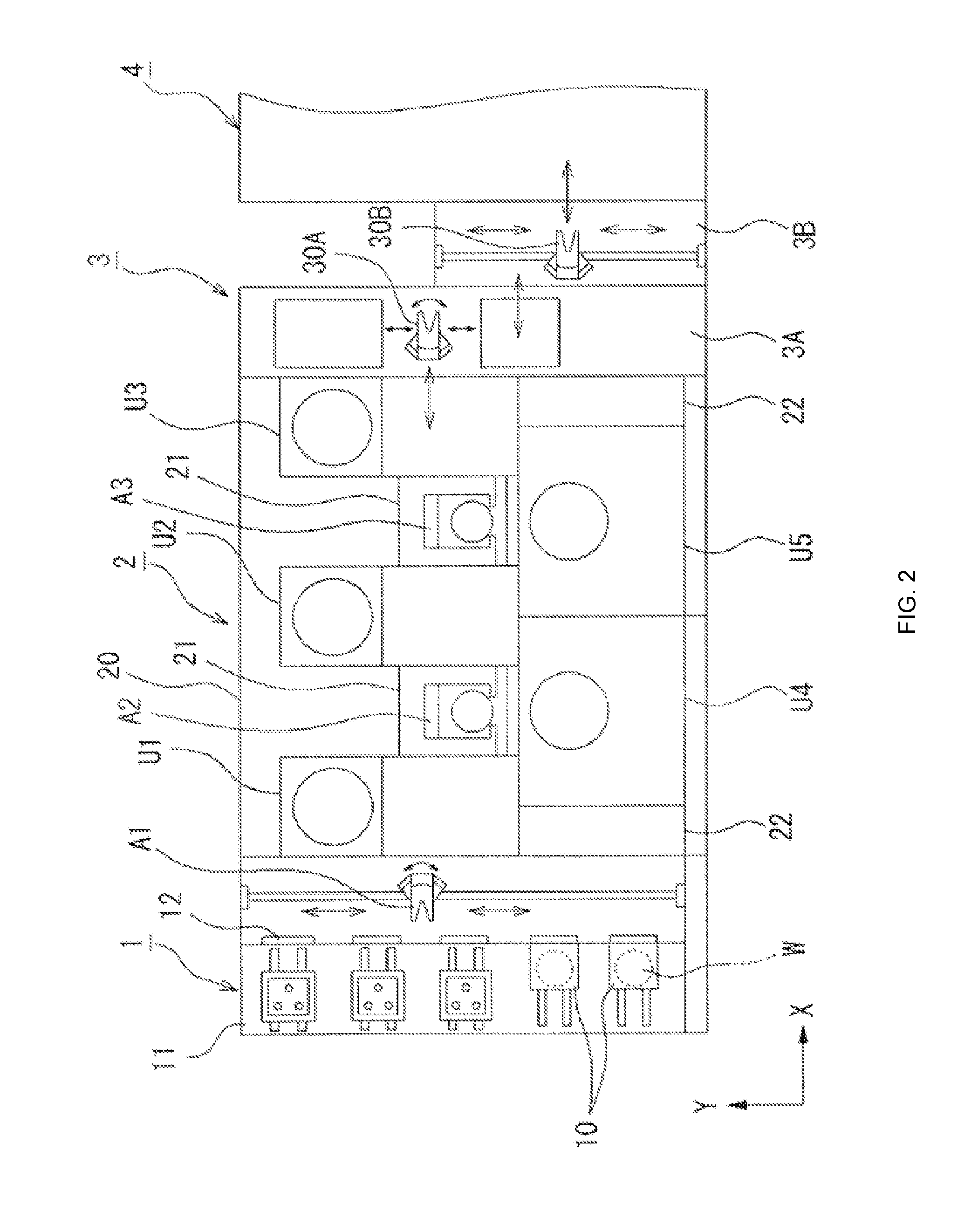

[0023]A coating and developing apparatus may be used for coating a wafer with a photoresist liquid and subsequently developing the wafer. Systems and methods described herein may lower photoresist printed wafer defectivity, such as defectivity associated with micro-bridging defects, by providing continuous resist movement (to prevent agglomeration of resist components, etc.) and high filtration number (Fn), where Fn is the effective number of times that the photoresist has been filtered (i.e., pushed or pulled through a filter) on the track.

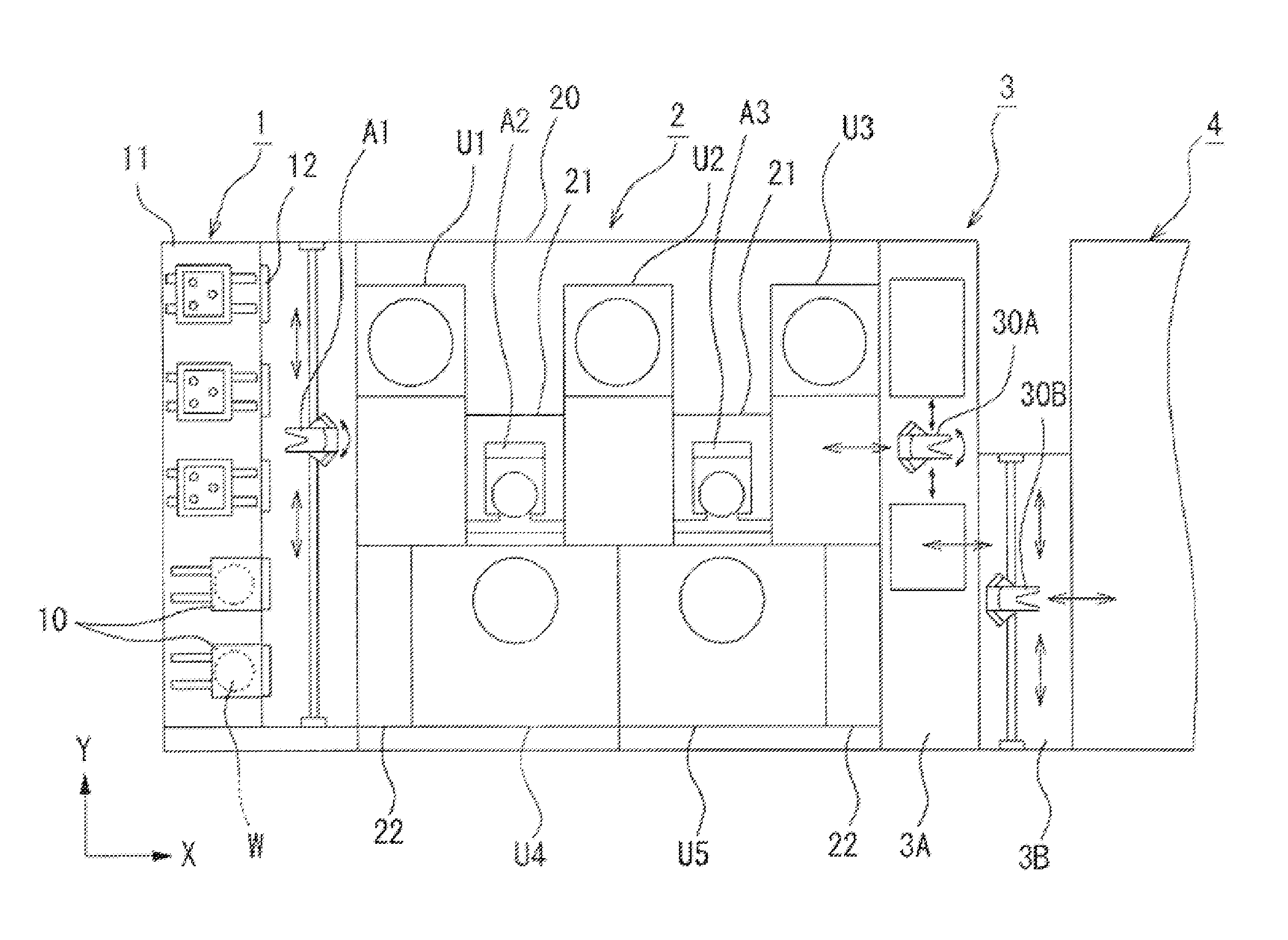

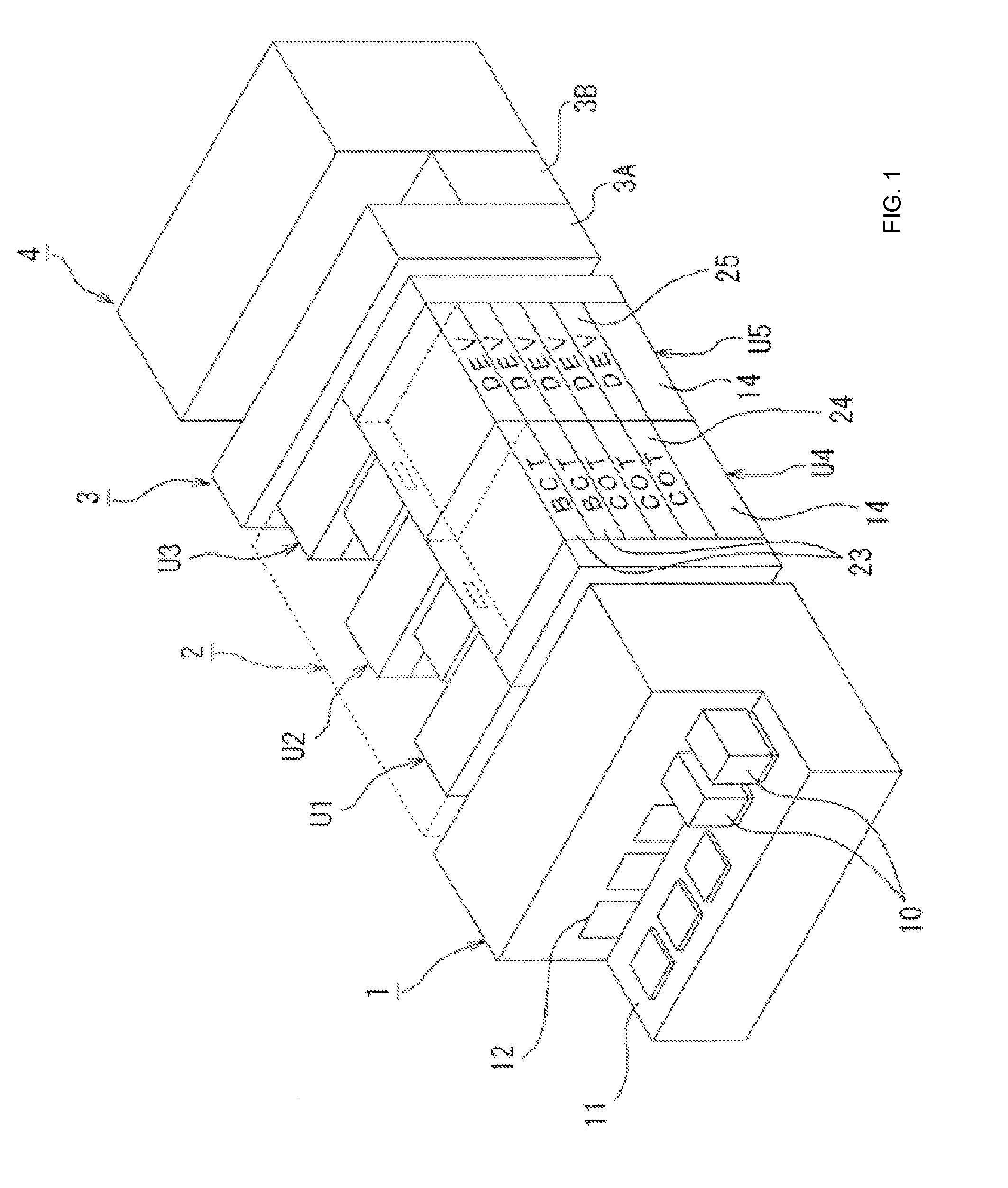

[0024]As shown in FIGS. 1 and 2, an example coating and developing apparatus may include a carrier station 1 through which a carrier 10, which may hermetically contain a plurality of (e.g., twenty five) wafers W as substrates to be processed, may be loaded and unloaded; a processing part 2 that may be configured to perform a resist coating process, a developing process, and so on to a wafer W taken out from the carrier station 1; an exposure part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com