Ecology fuel return systems

a fuel return system and ecology technology, applied in the direction of valve operating means/release devices, functional valve types, machines/engines, etc., can solve the problems of air leakage into the fuel system of the aircraft, the inability of traditional ecology fuel return systems to experience stability, and the localization of undesirable fuel-rich conditions in the combustor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

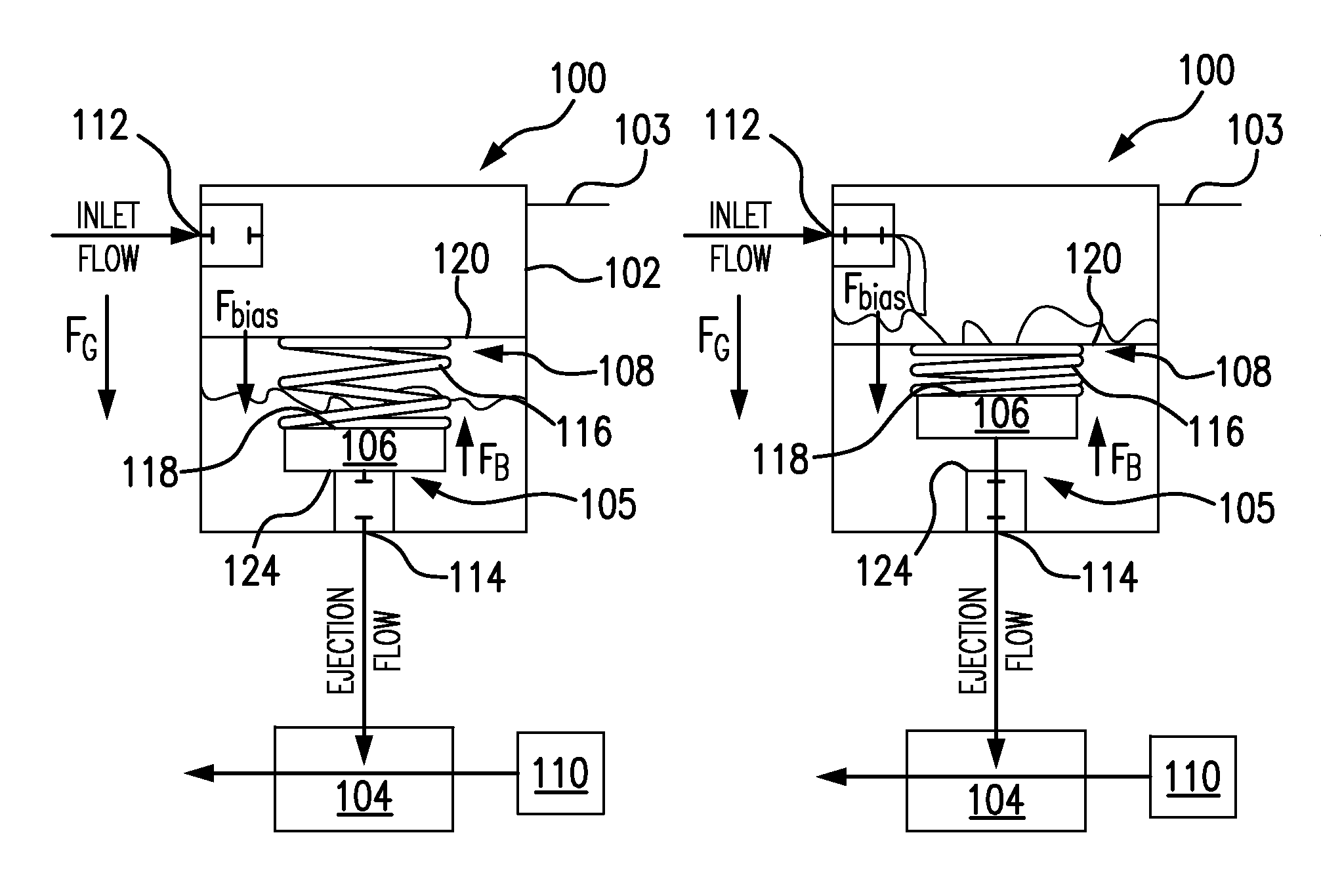

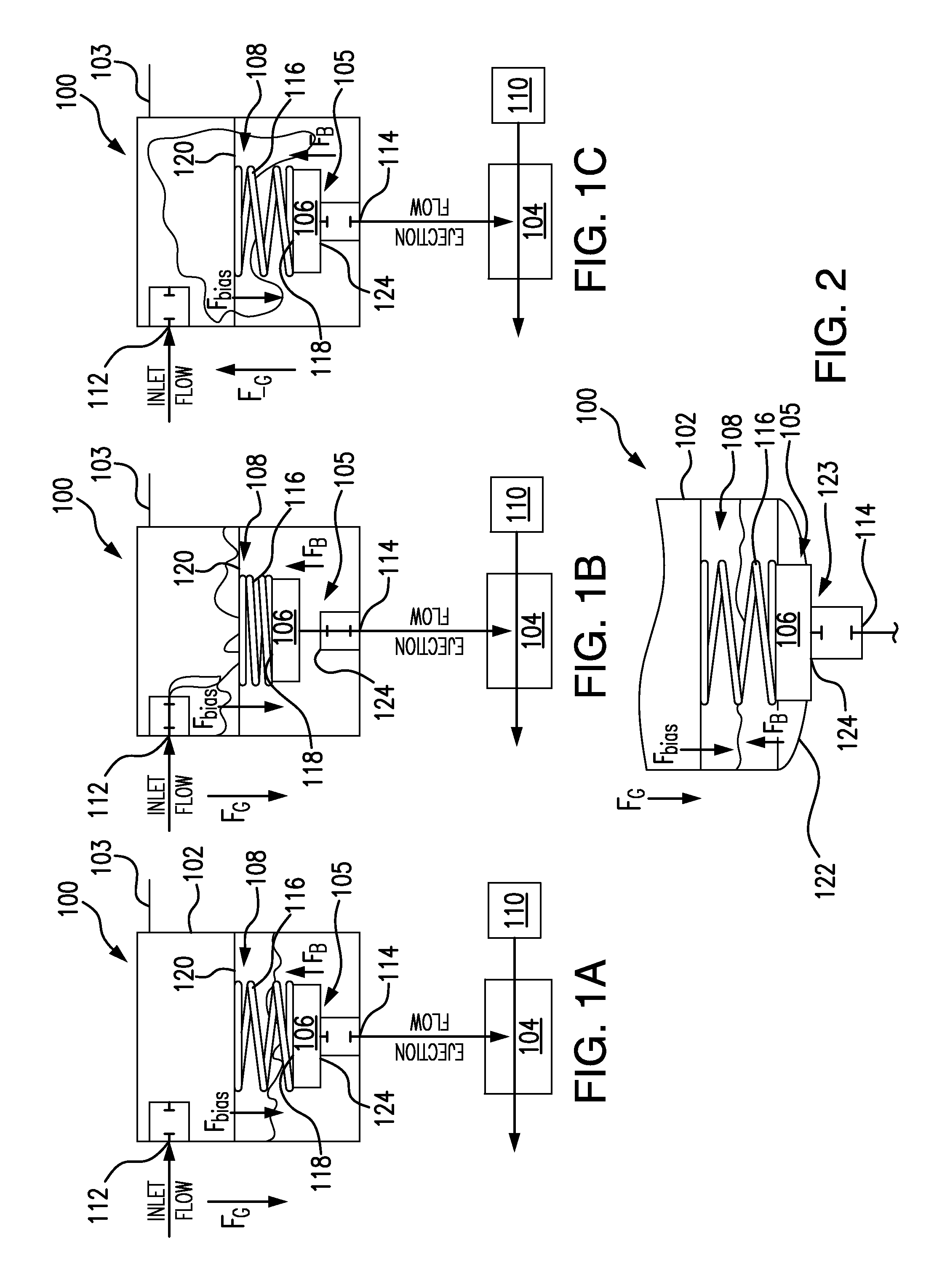

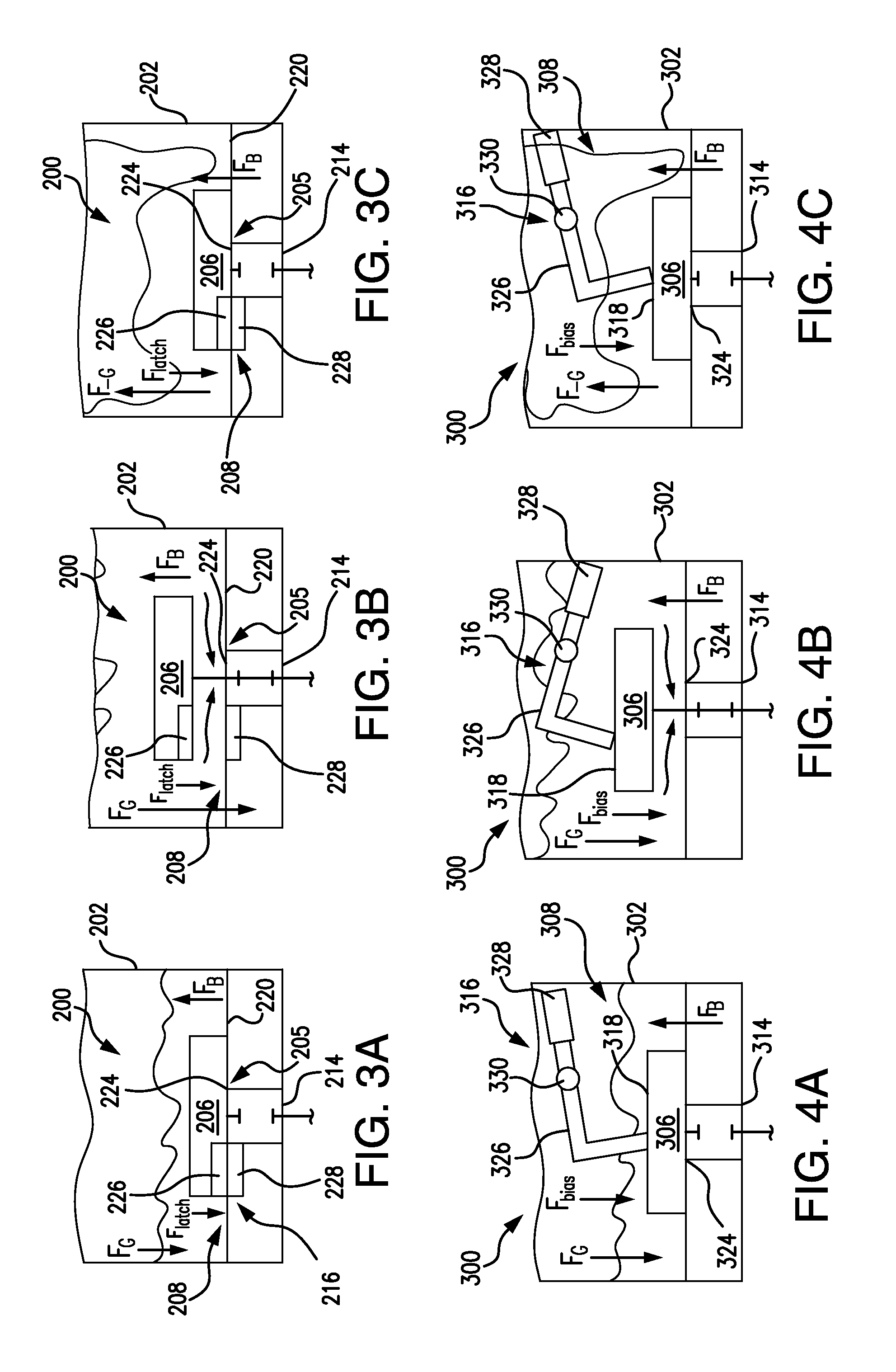

[0034]Reference will now be made to the drawings wherein like reference numerals identify similar structural features or aspects of the subject disclosure. For purposes of explanation and illustration, and not limitation, a perspective view of an exemplary embodiment of an ecology fuel return system in accordance with the disclosure is shown in FIG. 1A and is designated generally by reference character 100. Other embodiments of ecology fuel return systems in accordance with the disclosure, or aspects thereof, are provided in FIGS. 1B-7C, as will be described. The systems and methods of the invention can be used to reduce the entrainment of continuous airflow into the fuel system, for example during negative G loading events, such as during aircraft maneuvers and turbulence, where the tank is driven to accelerate against gravity.

[0035]As shown in FIG. 1A, an ecology fuel return system 100 includes a tank 102, an ejector pump 104, a boost pump 110, and a shut-off valve 105 with a floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com