Artificial environment for efficient uptate of fertilizers and other agrochemicals in soil

a technology of agrochemicals and soil, applied in the direction of biocide, plant growth regulators, animal husbandry, etc., can solve the problems of poor agrochemical use efficiency of plants, many soils and climates are not suitable for growing crops, and excessive application of agrochemicals has adverse effects on the environment, so as to reduce environmental damage and minimize exposure to agrochemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

The External Zone

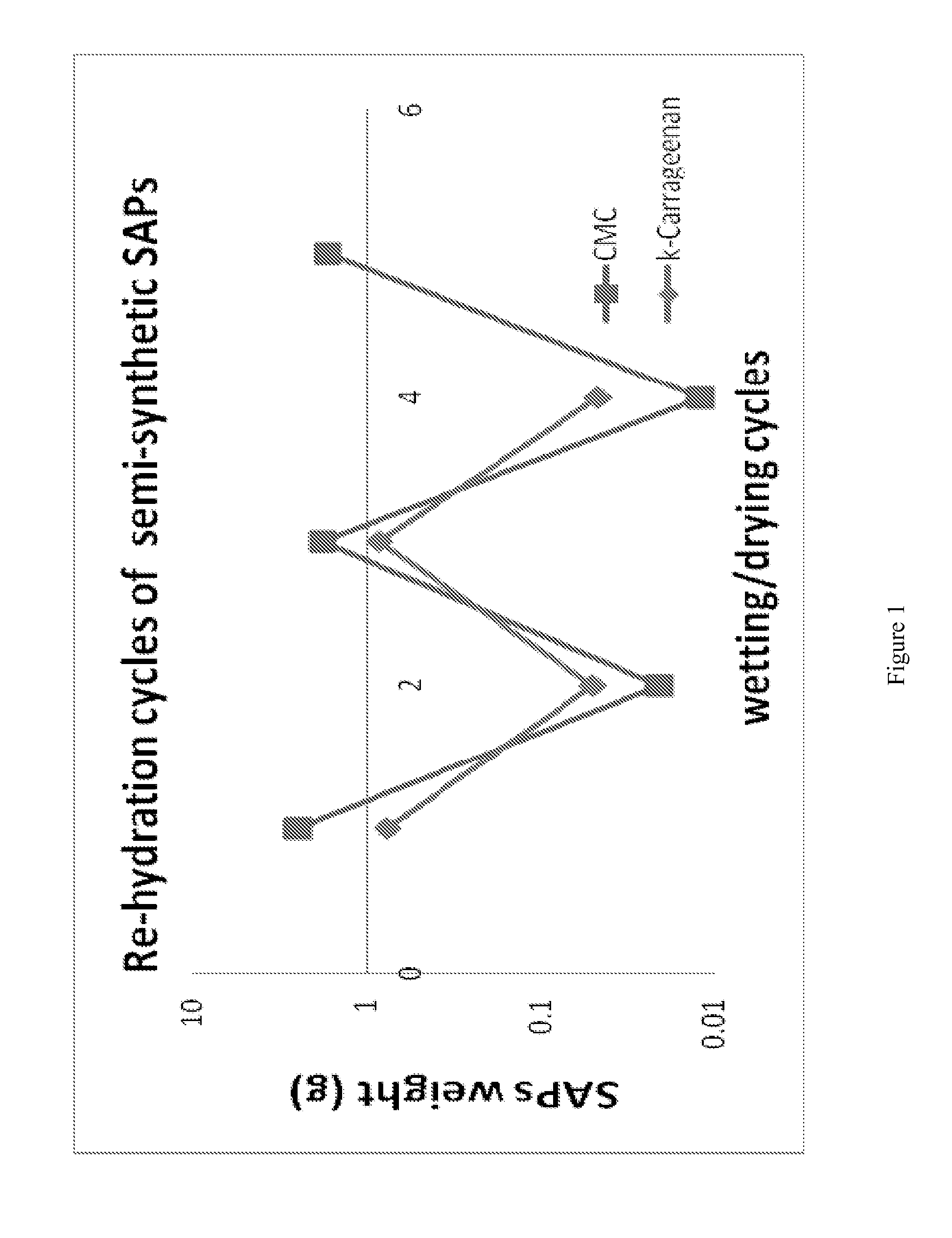

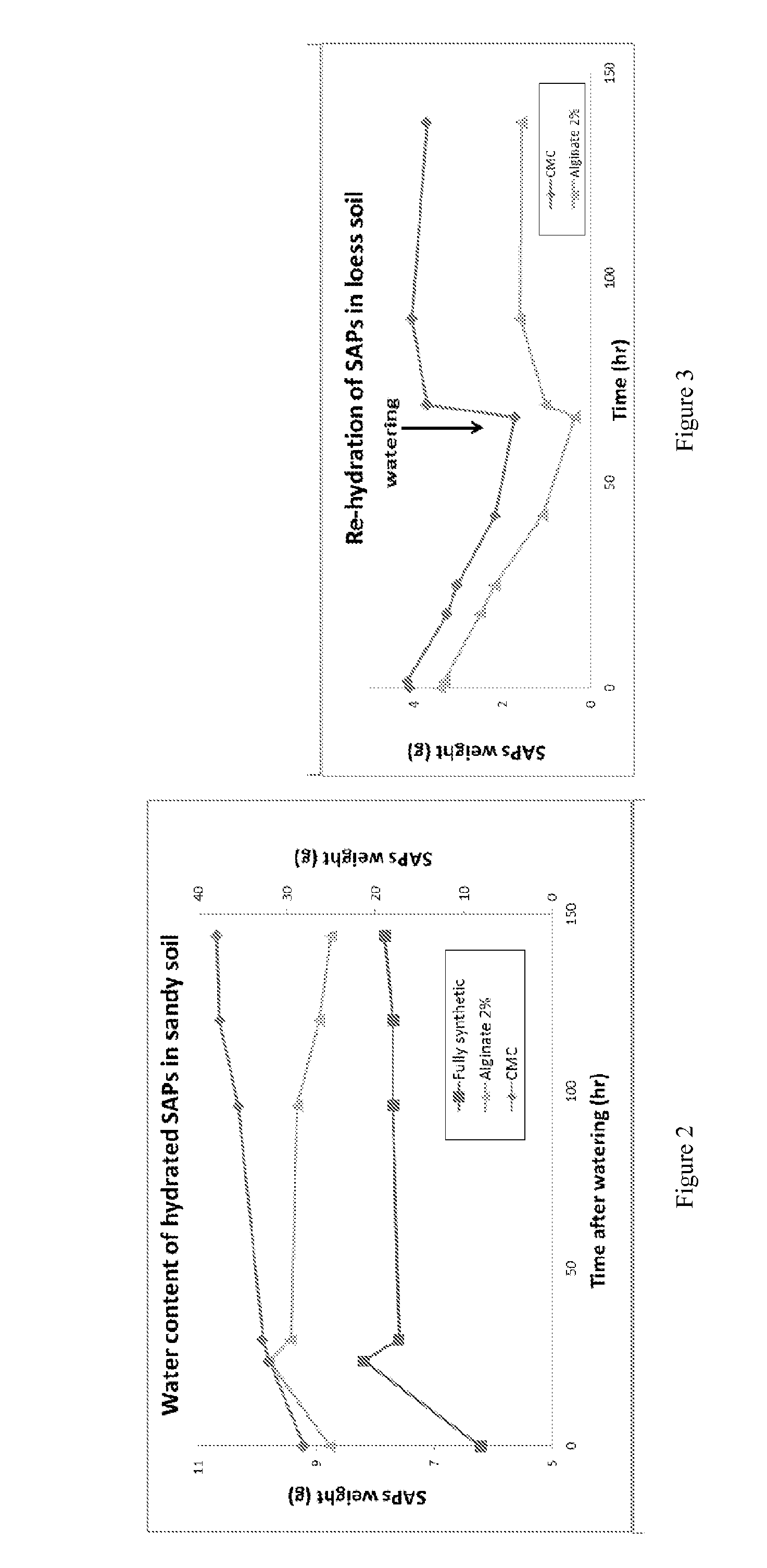

[0540]Four specific criteria were defined as the following, where each condition was tested experimentally:[0541]Mechanical resistance—maintain shape and geometry in the soil[0542]Swelling cycles—hydrate and dehydrate in corresponds to soil water content[0543]Oxygen permeability—maintain sufficient oxygen level to root activity[0544]Root penetration—allows the growth of root into it.

[0545]Mechanical resistance was tested by flushing water throughout a container filled with SAP and sand soil, Initial, final weights and dimensions were recorded. A pass mark was accepted for SAP that maintains a single element and didn't wash away or split into several parts. Three groups of SAP were synthesized and tested:

SAPsGroupPoly sugarSemi syntheticFully syntheticTypeAlginateCMC-g-poly (acrylic acid) / CeliteAcryliccomposite system CarboxymethylAcid / Acrylcellulose grafted polyacrylics acidAmidewith Celite as a filler.k-Carrageenan poly(acrylicacid)SAP

[0546]Each type of SAP was for...

example 2

The Internal zone

[0561]Three mechanisms were developed and evaluated to address the criteria of i) release rate of agrochemicals from the internal zone over a growing season, and ii) that no input residuals remain at the end of a predetermined action period. All the three, are based on integrating the input into a very dense polymer as the basic mechanism to slow down diffusion, in conjunction to a secondary mechanism that will additionally decrease the diffusion rate:[0562]1) Highly Cross Linked Polymer with silicon coating (xLP-Si);[0563]2) Highly Cross linked Poly Acrylic / poly sugar with filler (xLP-F); and[0564]3) Hybrid system (SiCLP-).

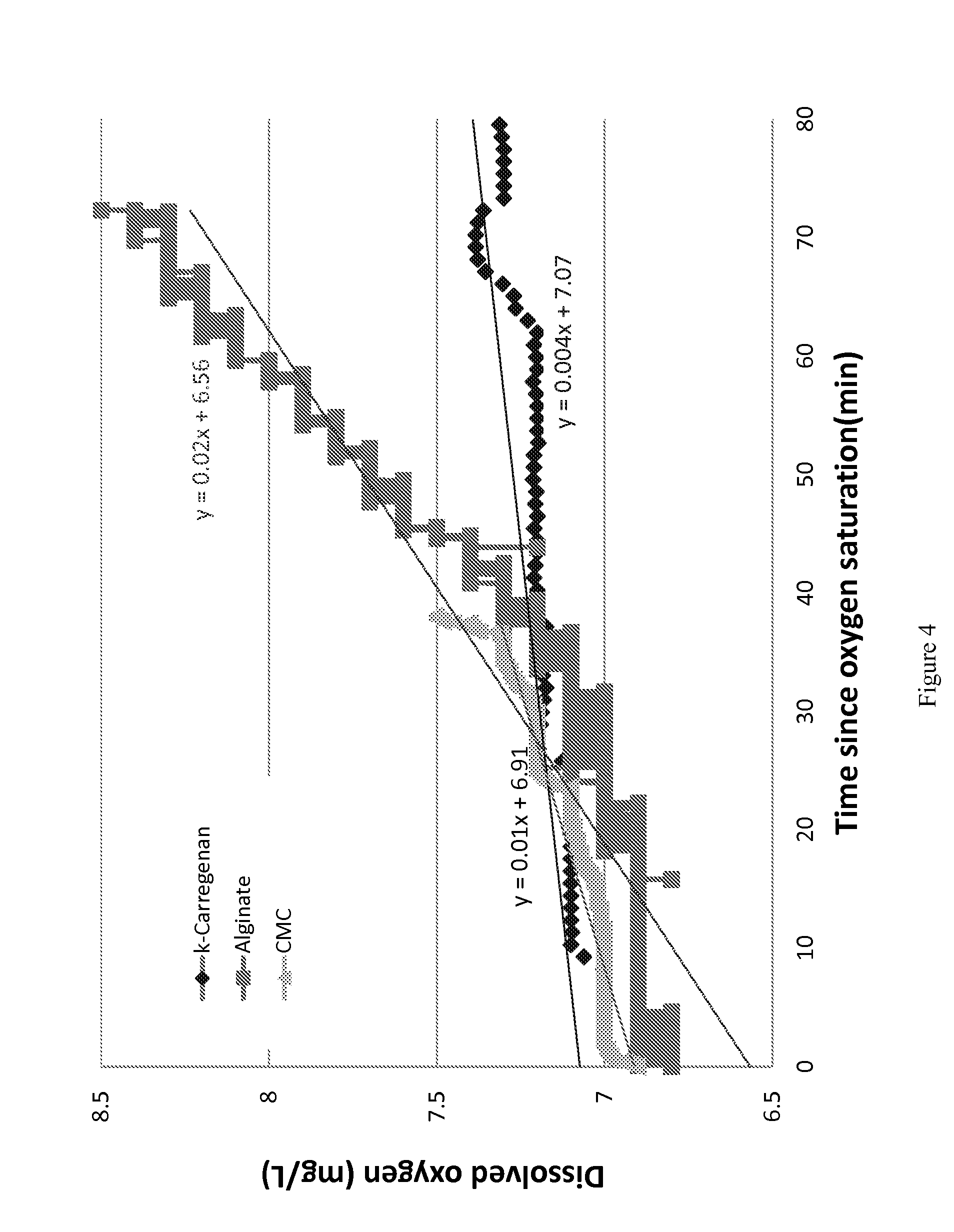

[0565]The first mechanism is based on precipitation of silica, originated from silica water, on the surface of the polymer (FIG. 4).

[0566]The second mechanism is based on filler, made from bentonite, integrated into the polymer and decreases sharply its diffusion properties (FIG. 6).

[0567]The third mechanism is to mix the silica with the acrylic ...

example 3

Stability, Dimensions, and Mechanical Resistance of Hydrogels Applied to a Field Plot

Objective

[0571]The objective of this example was to study the sustainability in soil, hydrated dimensions and mechanical resistance of different types and sizes of hydrogel within a field plot. Furthermore, root penetration into these types of hydrogels was studied.

Hydrogels

[0572]The types and sizes of hydrogels are described in Table 3 below:

SmallMediumLarge(hydrated(hydrated size(hydrated sizeNo.Chemical compositionsize of 2-3 cm)of 4-5 cm)of 7-8 cm)Geometry1Fully synthetic+Box2Semisynthetic CMC 6%+++Cylinder / Box / CylinderAAm3Semisynthetic CMC 6% AA+Box4Semisynthetic CMC 25%+BoxAA5Semisynthetic CMC 50%+++Cylinder / Box / CylinderAA6Polysugars Alginate+Cylinder

[0573]The fully synthetic hydrogel had the composition of the fully synthetic hydrogel described in Example 1.

[0574]The semisynthetic CMC 6% AAm hydrogel comprises 6% CMC relative to the acrylic acid monomers (Acrylamide-acrylic) and was made by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total volume | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com