Easy open pouches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

[0060]The following examples illustrate certain particular embodiments of films suitable for use in forming packages and protective strips and are not to be interpreted as limiting. In the following example, resin composition percentages are based on the total weight of each film layer.

example 1

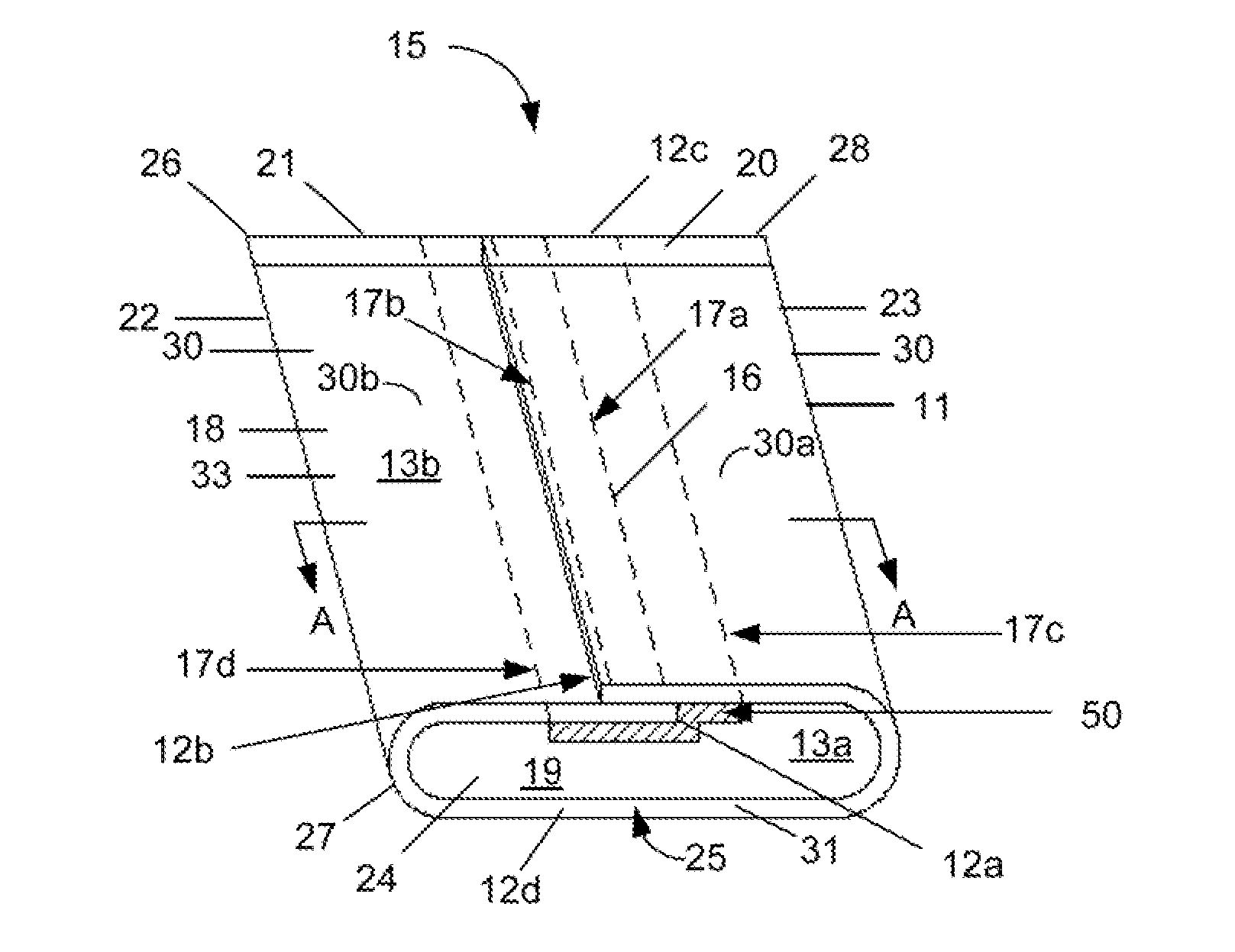

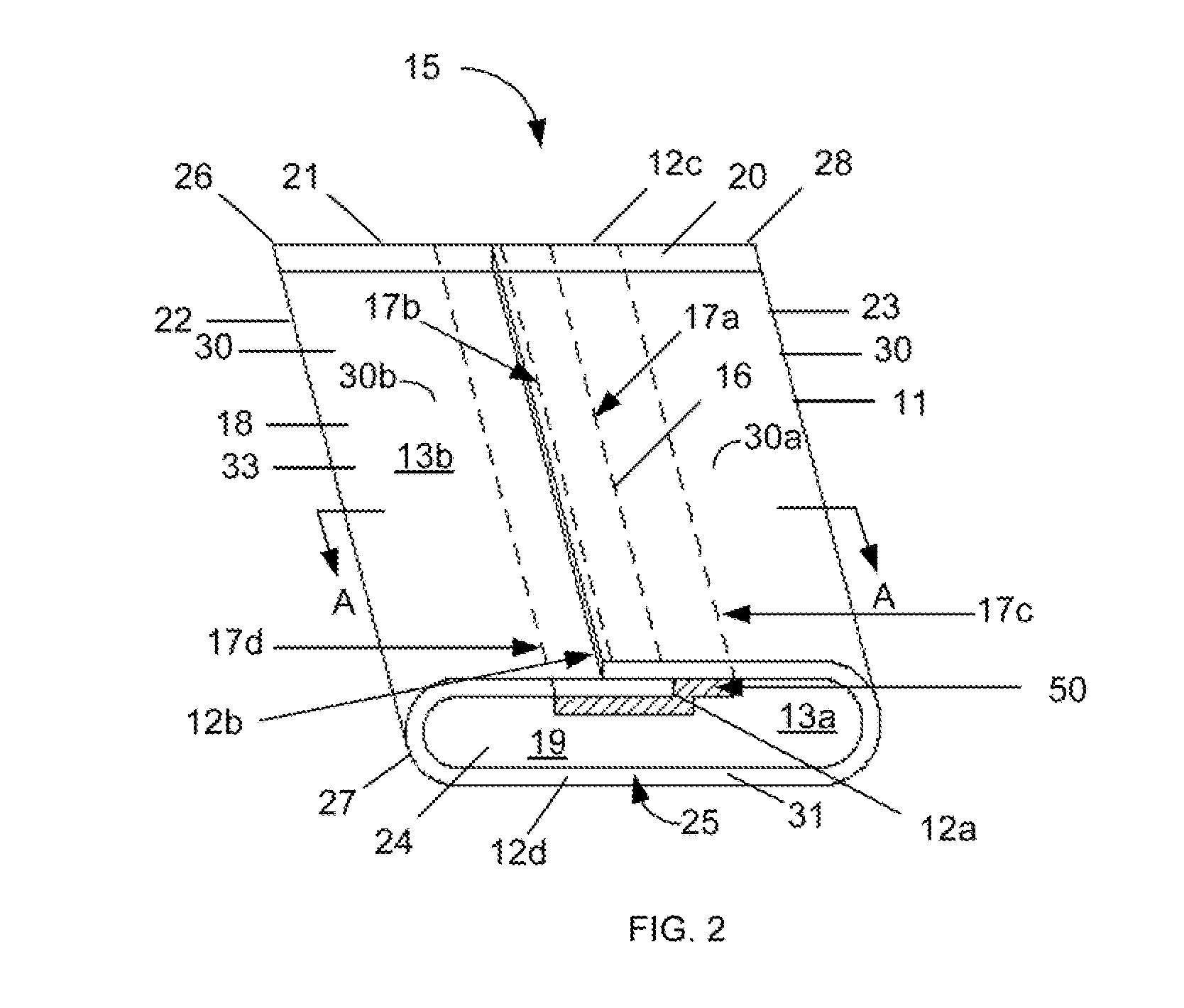

[0061]A package according to the present invention, as generally illustrated in FIG. 2, is produced from a film $00 comprising a laminated structure as illustrated in FIG. 13. The package also includes a protective strip as generally illustrated in FIG. 2, which is produced from a film 600 comprising a peelable / fracturable heat sealing layer 601, a peelable / fracturable second layer 602, and a third heat sealing layer 603, as illustrated in FIG. 14. In this example, film 500 includes a 2.0 mil thick, seven-layer blown coextruded film comprising a first peelable / fracturable heat sealing layer 501, a peelable / fracturable second layer 502, a third layer 503, a fourth layer 604, a fifth layer 505, a sixth layer 506, and a seventh layer 507. The seven-layer blown film was adhesively laminated via adhesive layer 508 to a 35-gauge thick, aluminum foil layer 509. A second adhesive layer 510 adhesively laminated a 60-gauge thick, biaxially oriented cast film of polyamide 511 to the foil layer...

example 2

[0080]A package according to the present invention was made, as generally described above for Example 1 with films 500 and 600, except for film layers 501 and 502 of film 500 had the following structure and layer compositions:

[0081]Layer 501 (Sealant): 99 wt.-% polypropylene copolymer (PP)-Pro-fax SA861 (LyondellBasell Industries Holdings, B.V., The Netherlands)+1.0 wt.-% processing additives

[0082]Layer 502 (Peelable): 81 wt.-% ethylene vinyl acetate copolymer (EVA)-DuPont™ Elvax® 3135X (E.I. du Pont de Nemours and Company, Inc., Wilmington, Del., USA)+19 wt.-% polybutene-1 (PB)-PB 8640M (LyondellBasell Industries Holdings, B.V , The Netherlands)

[0083]The packages according to the invention are preferably fabricated continuously from a continuous web or roll stock. The roll stock is slit to a desired width and fed into a bag making equipment, wherein the first and second sides of the packaging film are brought together to form a tube member in a lap-type or butt-type tape seal confi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com