Cut-Resistant Hockey Sock

a technology for hockey socks and socks, applied in the field of hockey socks and accessories, can solve the problems of not always staying in place, socks are uncomfortable to wear, and still refuse to wear such socks, and achieve the effect of preventing the cutting of the back of the user's leg and good freedom of movement for the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

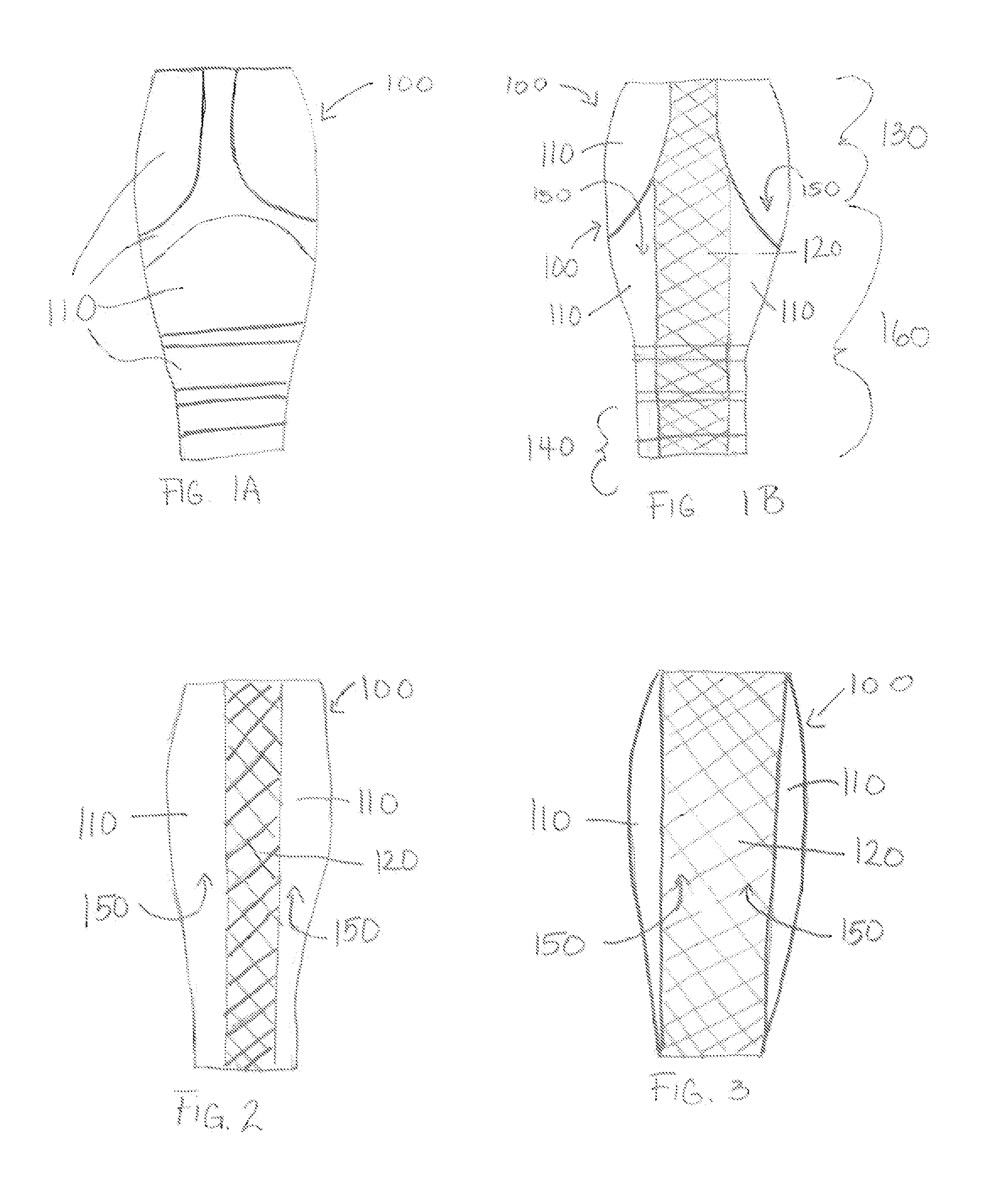

[0026]FIGS. 1A and B illustrate the present invention. FIG. 1A shows the front view of a hockey sock 100 bearing a pattern. Other patterns and colours are contemplated. Socks without patterns or which are monochrome are also contemplated. The front of the sock comprises non-cut-resistant fabric 110, that is, fabric that is vulnerable to being cut by a hockey blade, which is the typical fabric of prior art hockey socks. Cut-resistant material is not required on the front of the hockey sock since the player typically wears a shin pad and guard. The typical shin pad and guard cover and protect the front and sides of the lower leg. As such, any cutting force on the front or sides of the lower leg, while potentially damaging to the front or side of the hockey sock of the present invention, will not injure the player.

[0027]FIG. 1B shows the rear view of the hockey sock of FIG. 1A. As illustrated in hash marks, cut-resistant material 120 is positioned along the vertical axis of the sock, a...

second embodiment

[0029]FIG. 2 illustrates the rear view of the present invention comprising a consistent width of the cut-resistant portion 120 all along the vertical axis of the hockey sock 100, but not the side of the sock 150. The front view of this embodiment comprises non-cut-resistant fabric 110.

third embodiment

[0030]FIG. 3 illustrates the rear view of the present invention comprising a consistent width of the cut-resistant portion 120 all along the vertical axis of the hockey sock 100, and extending to the sides of the sock 150. The front view of this embodiment comprises non-cut-resistant fabric 110. This embodiment can be worn, for example, by a player whose shin guard-pad is not wide enough to cover the sides of the sock 150. The illustrated embodiment does not include a pattern, although patterns are contemplated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com