Intramedullary anchor-screw fracture fixation

a technology of applied in the field of intramedullary anchoring and fixing fractures, can solve problems such as large scars, and achieve the effects of minimal scarring, minimal scarring, and minimal treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

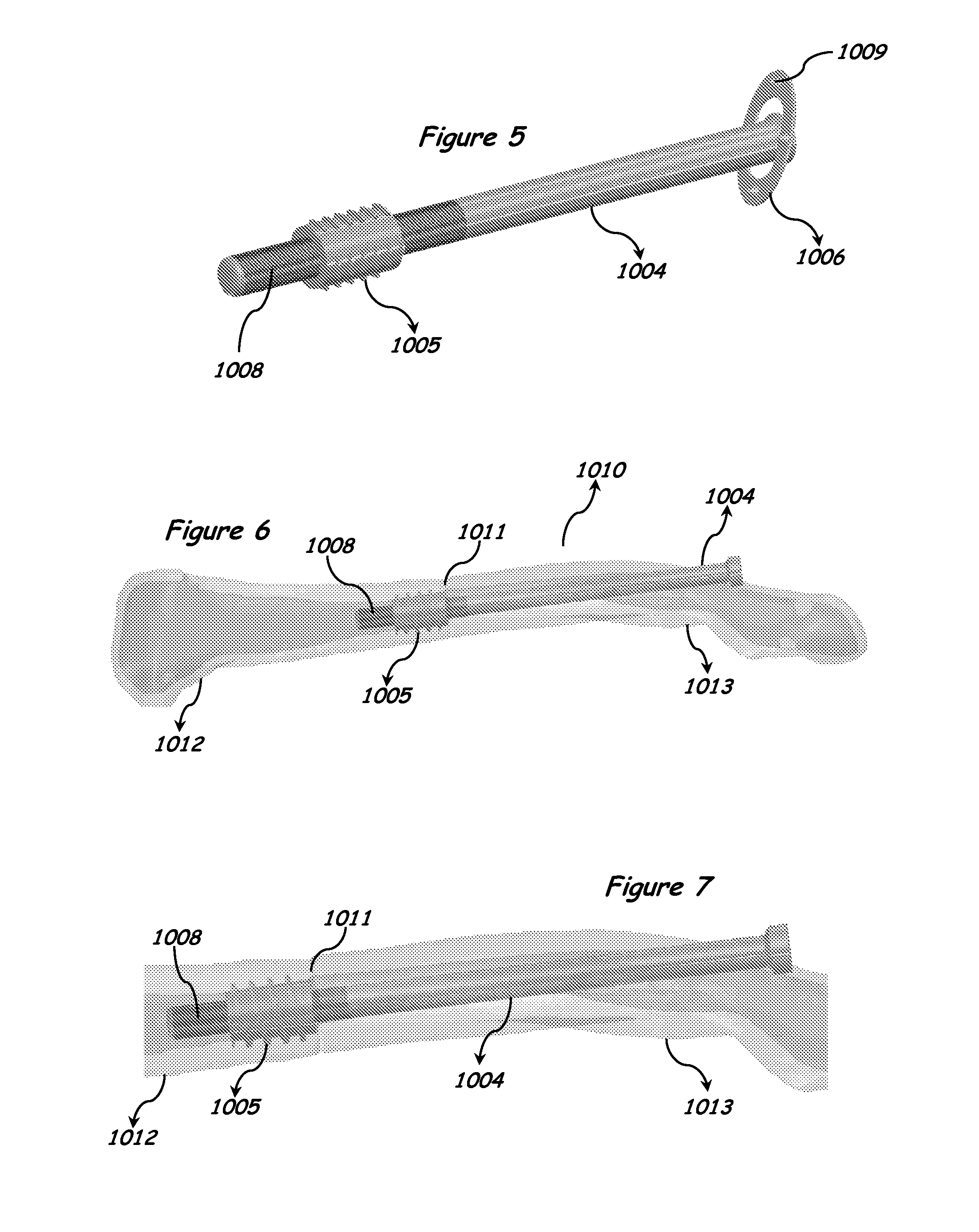

[0015]The preferred embodiment of the present invention is shown in FIGS. 1-7.

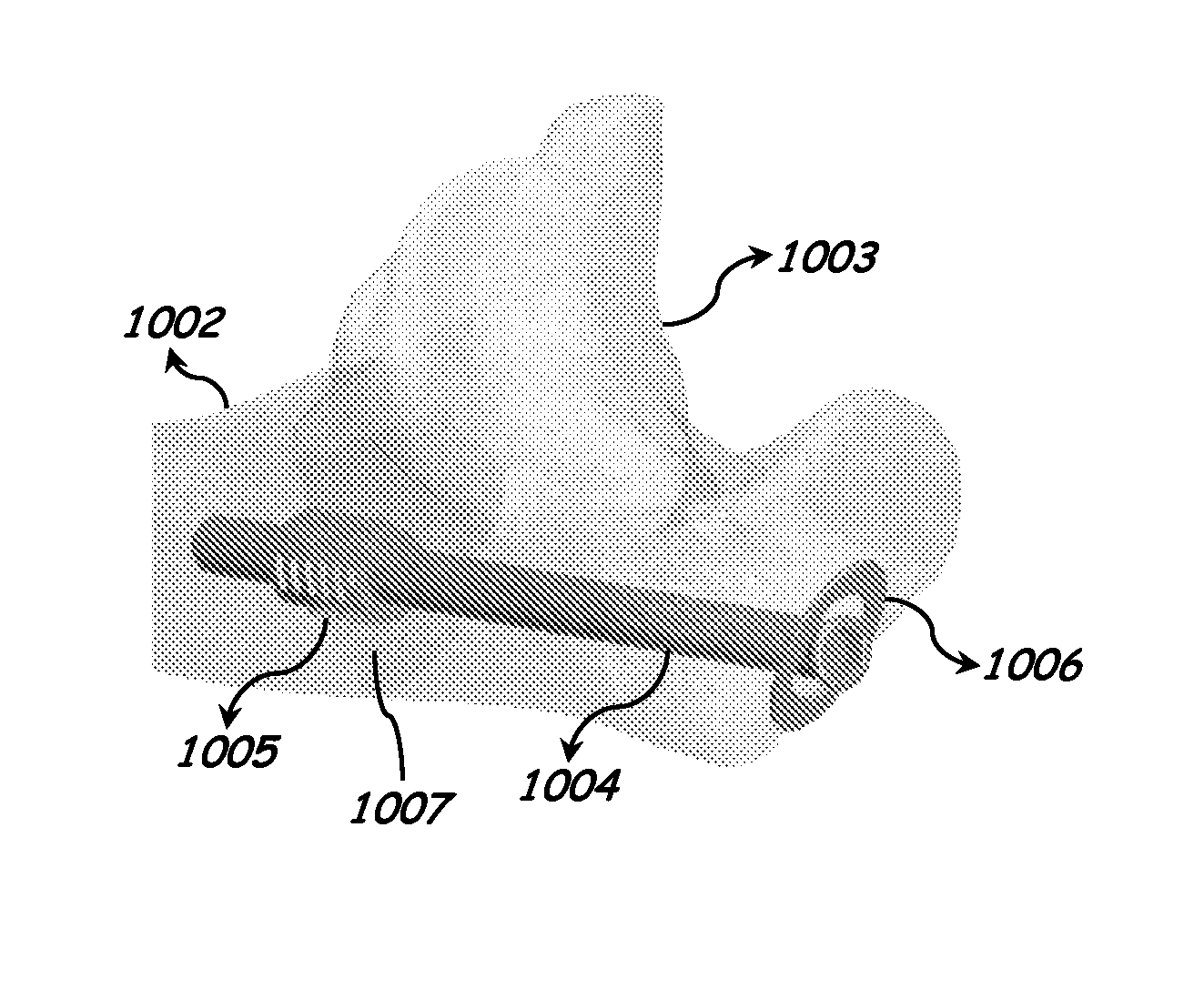

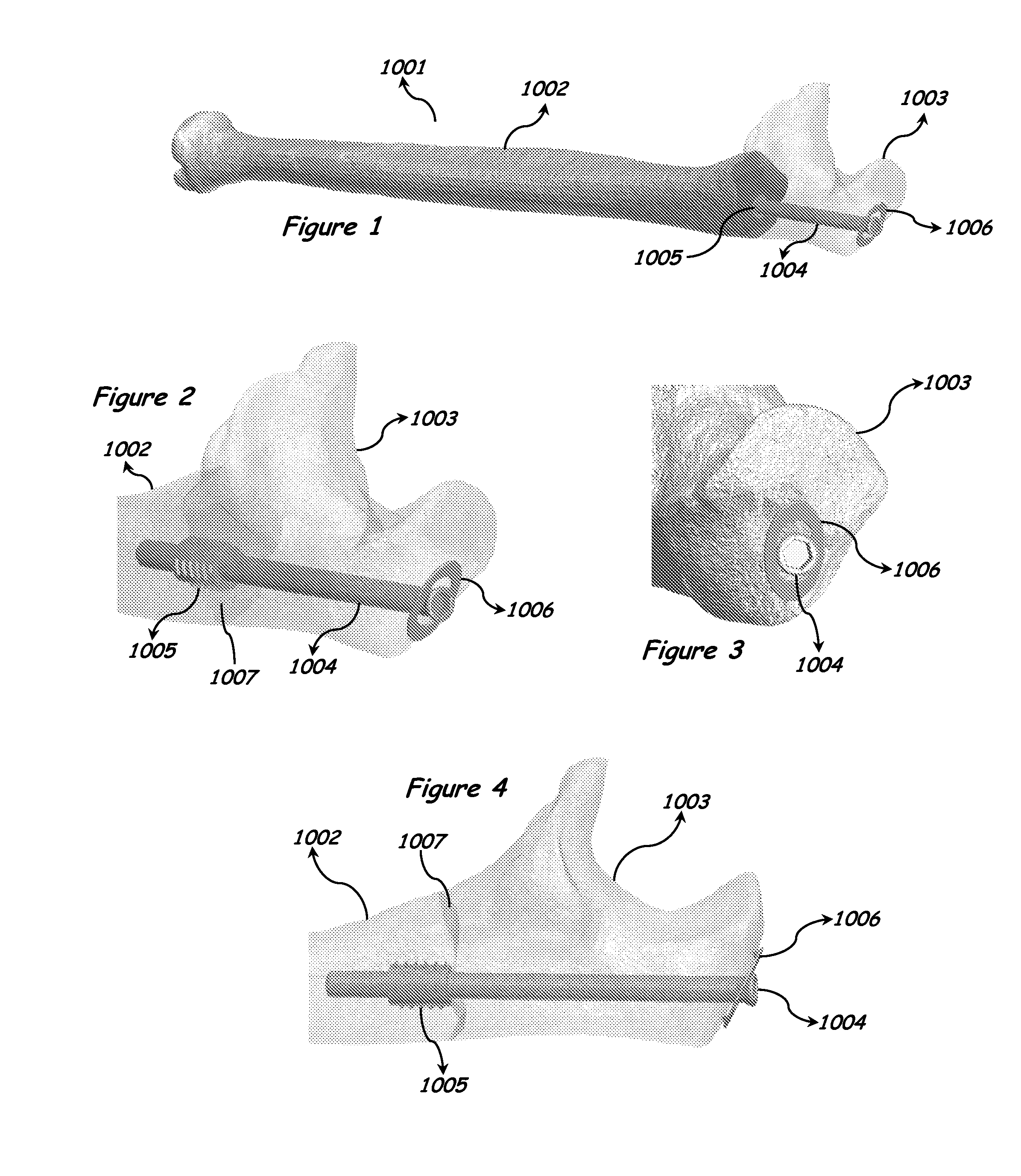

[0016]As shown in FIG. 1, a perspective view of the ulna 1001 showing a distal fracture fragment 1002 and a proximal fracture fragment 1003. The anchor-screw device consists of: a distal threaded nut 1005 that is screwed into the distal fragment 1002, a proximal screw 1004 that is implanted through a hole in the proximal fragment 1003, and a spiked washer 1006 that is inserted between the proximal fragment 1003 and the proximal screw 1004.

[0017]As shown in FIG. 2, a perspective view of the elbow showing the proximal fragment 1003, the distal fragment 1002 and the fracture site 1007, the threaded nut 1005, the proximal screw 1004 and the spiked washer 1006.

[0018]As shown in FIG. 3, a close-up view of the elbow showing the proximal fragment 1003, the proximal screw 1004 and the spiked washer 1006.

[0019]As shown in FIG. 4, a side view of the elbow showing the proximal fragment 1003, the distal fragment 1002 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com