Electronic cigarette packing case and method for manufacturing same

a technology for electronic cigarettes and packaging cases, which is applied in the field can solve the problems of easy damage, deformation, and easy breakage of electronic cigarette packaging cases during transportation, and achieve the effect of convenient rotation of hooks, not easily broken, damaged or bent during transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

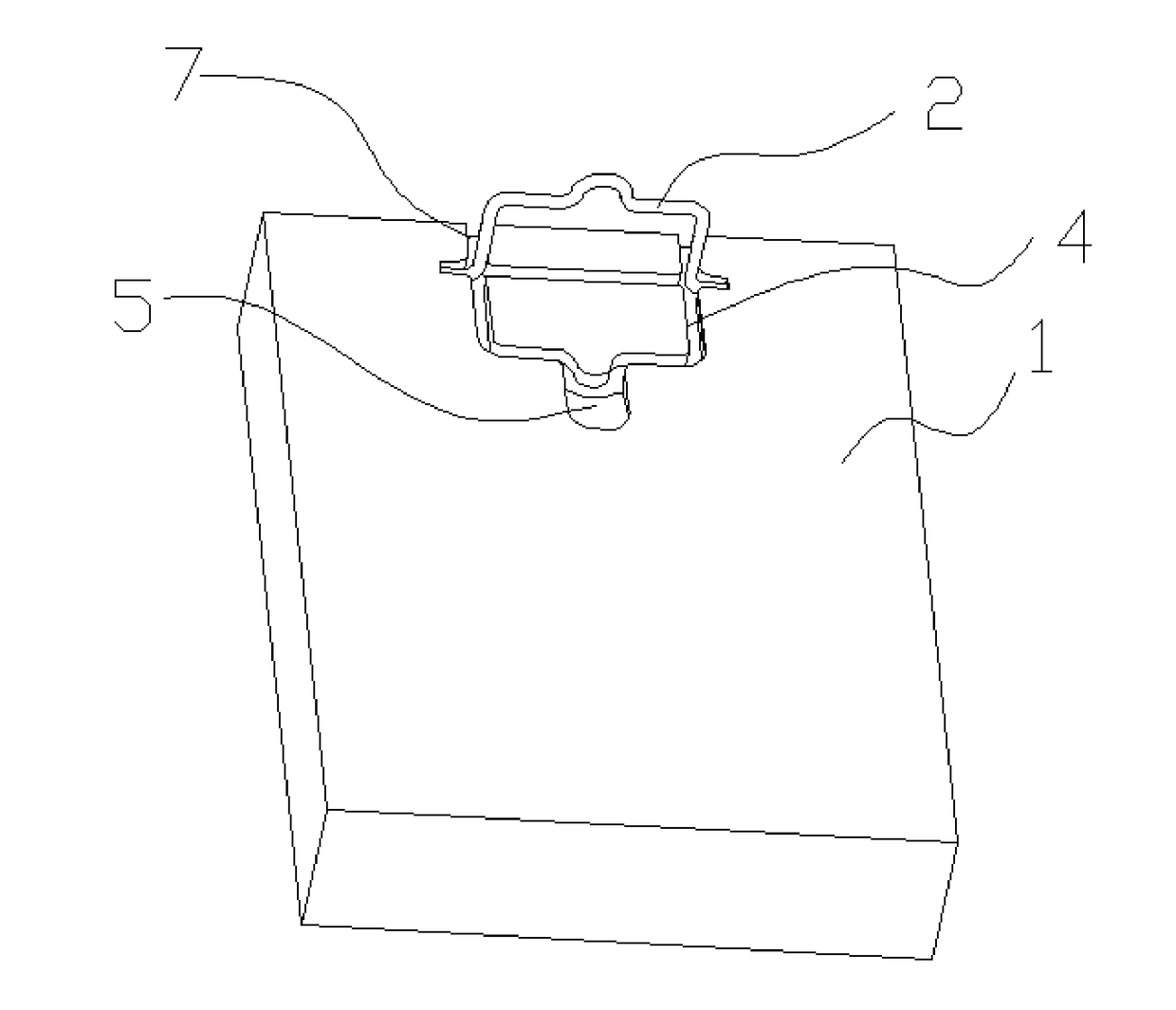

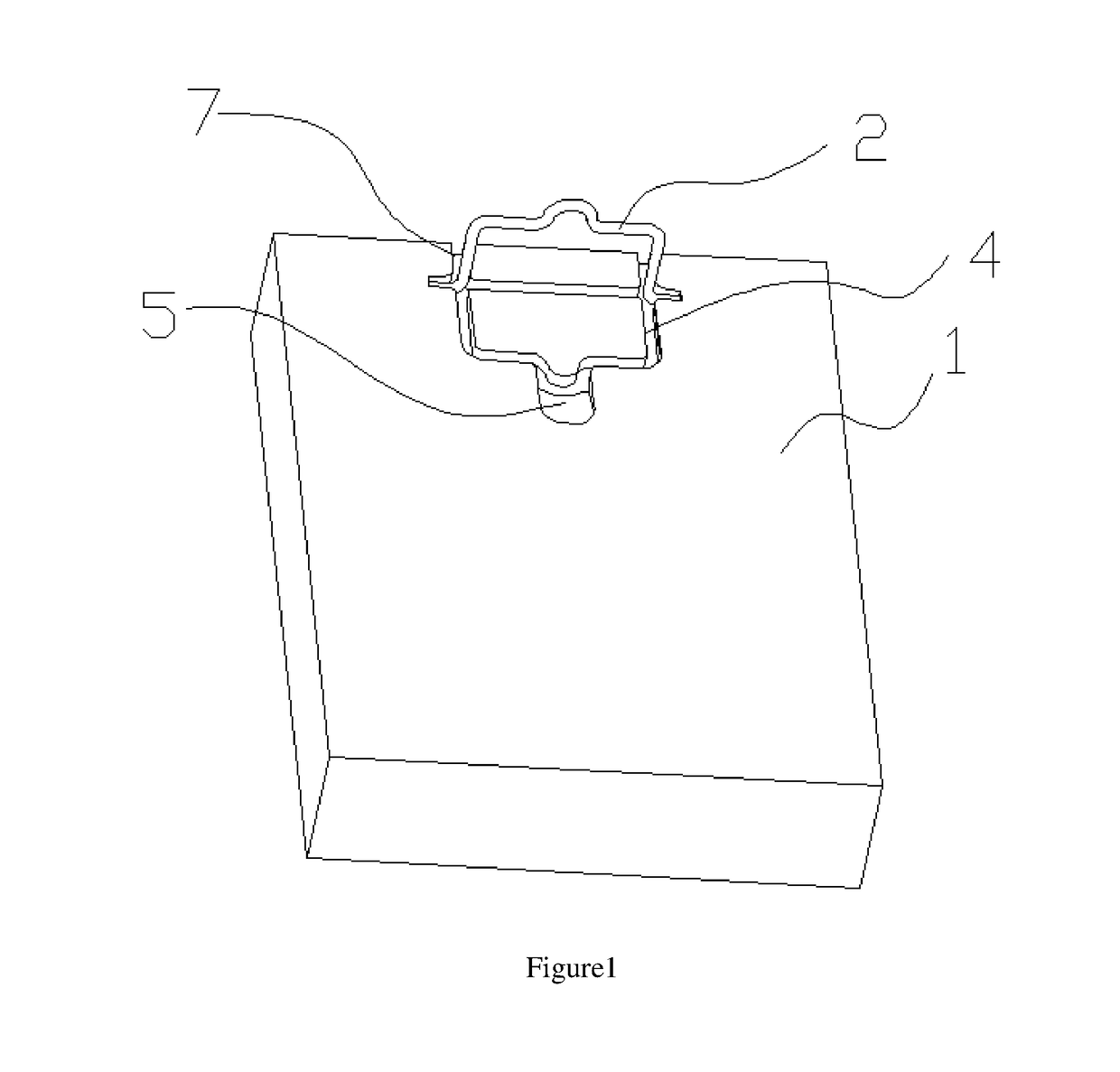

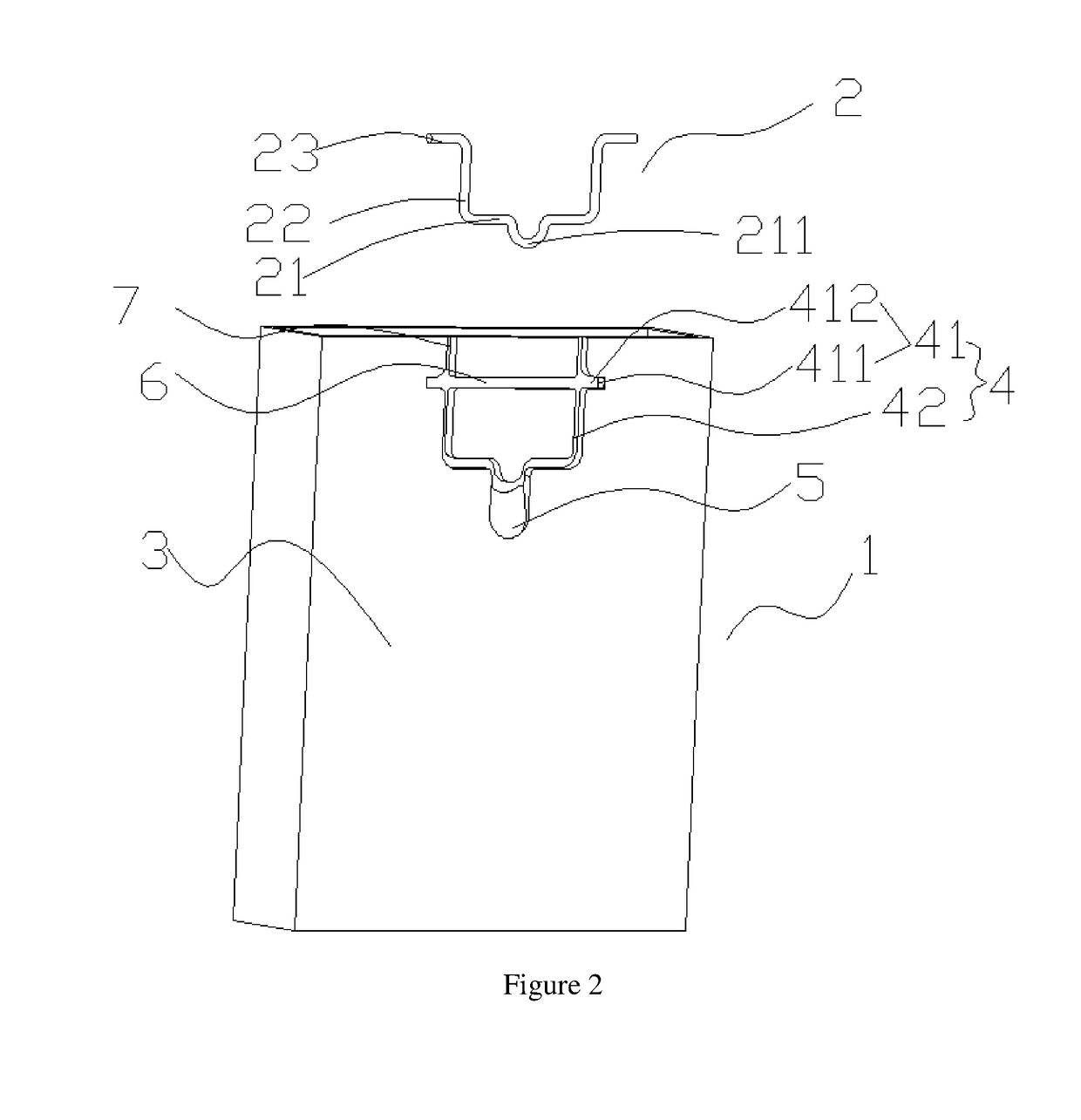

[0053]Refer to FIG. 1 to FIG. 5 in the electronic cigarette packing case, in order to make it convenient to install the hook 2 on the case body 1, the support 22 is an elastomer, two parts of the support portion 22 can close to or away from each other under the action of an external force. The hook 2 is formed by bending an elastic steel wire, a protruding part 211 which is used for hanging the hook 2 on an external support member is formed by an outward bulge of a part of the hanging portion 21.

[0054]The protruding part 211 can be an uplift arch, or an uplift sharp, by hanging the sharp part or the arch portion on the outer support piece, a position of the electronic cigarette packing case can be limited, thus the hanging is more stable.

[0055]In order to ensure the hook 2 is difficult to falling out from the first accommodation space 4 when the hook 2 is accommodated in the first accommodation space 4, a convex strip 44 (shown in FIG. 6) is defined at a position of an internal side...

second embodiment

[0058]Refer to an electronic cigarette packing case in the second embodiment in FIG. 7, and FIG. 8 and FIG. 9. Specifically, as shown in FIG. 7, one difference is that, the hook 2 is a plate plastic piece, the hanging portion 21, the support portion 22 and the connecting portions 23 are integrally formed by an injection molding. By the injection molding, the hook 2 can be processed to a mass production, saving a process, and to further save production costs, but also makes a manufacture more simple.

[0059]In order to make it convenient to hang the hanging portion 21 on the outside support piece, a hanging hole 212 which is used for hanging the hook 2 on the external support member is defined at the hanging portion 21. Meanwhile, to adapt to different external support members, a range of a diameter of the hanging hole 212 can be 10 mm to 25 mm, preferably, a diameter of 15 mm of the hanging hole 212 is selected.

[0060]Meanwhile, the support portion 22 may be an elastomer, two parts of ...

third embodiment

[0062]An electronic cigarette packing case of a third embodiment is shown in FIG. 10, FIG. 11 and FIG. 12, the support portion 22 is a metal shrapnel, the connecting portions 23 comprise a rotating shaft, the support portion 22 is bent and covers an outside of the rotating shaft.

[0063]In the above situation, in order to facilitate an installation, the rotating shaft can move along an axial direction of the rotating shaft under an action of an external force.

[0064]The hanging portion 21 is a plate shaped piece, a concave 213 which is used for hanging the hook 2 on the external support member is defined at a side of the hanging portion 21 which is close to the connecting portions 23. Understandably, a shape of the concave 213 can be various, such as an arc shape, a triangle or a rectangle, and so on.

[0065]A specific installing process is that, two rotating shafts move in opposite directions to ensure that one end of the metal shrapnel which is coated in a rotating shaft can just dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com