Rotating electrical machine connection component and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

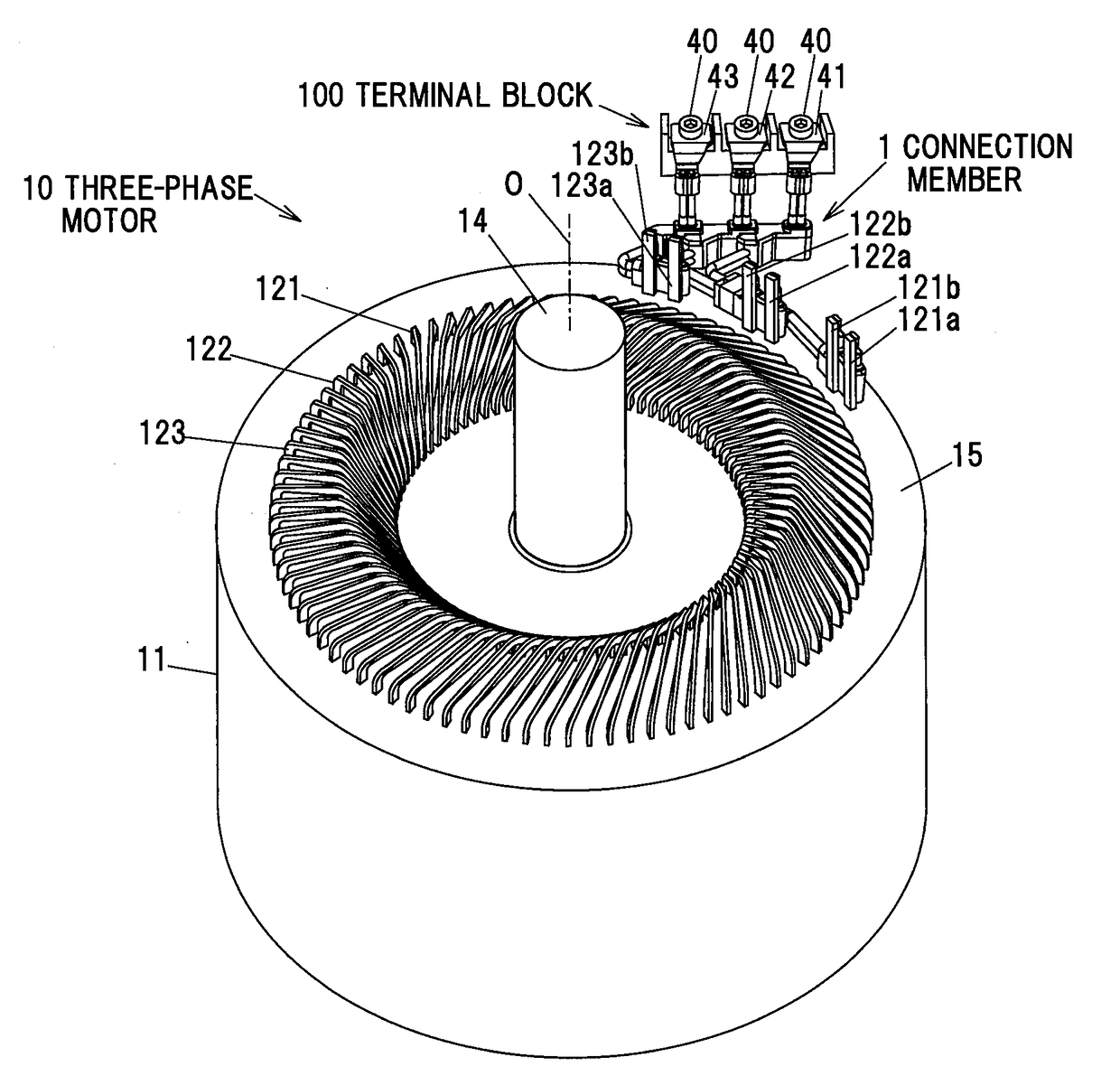

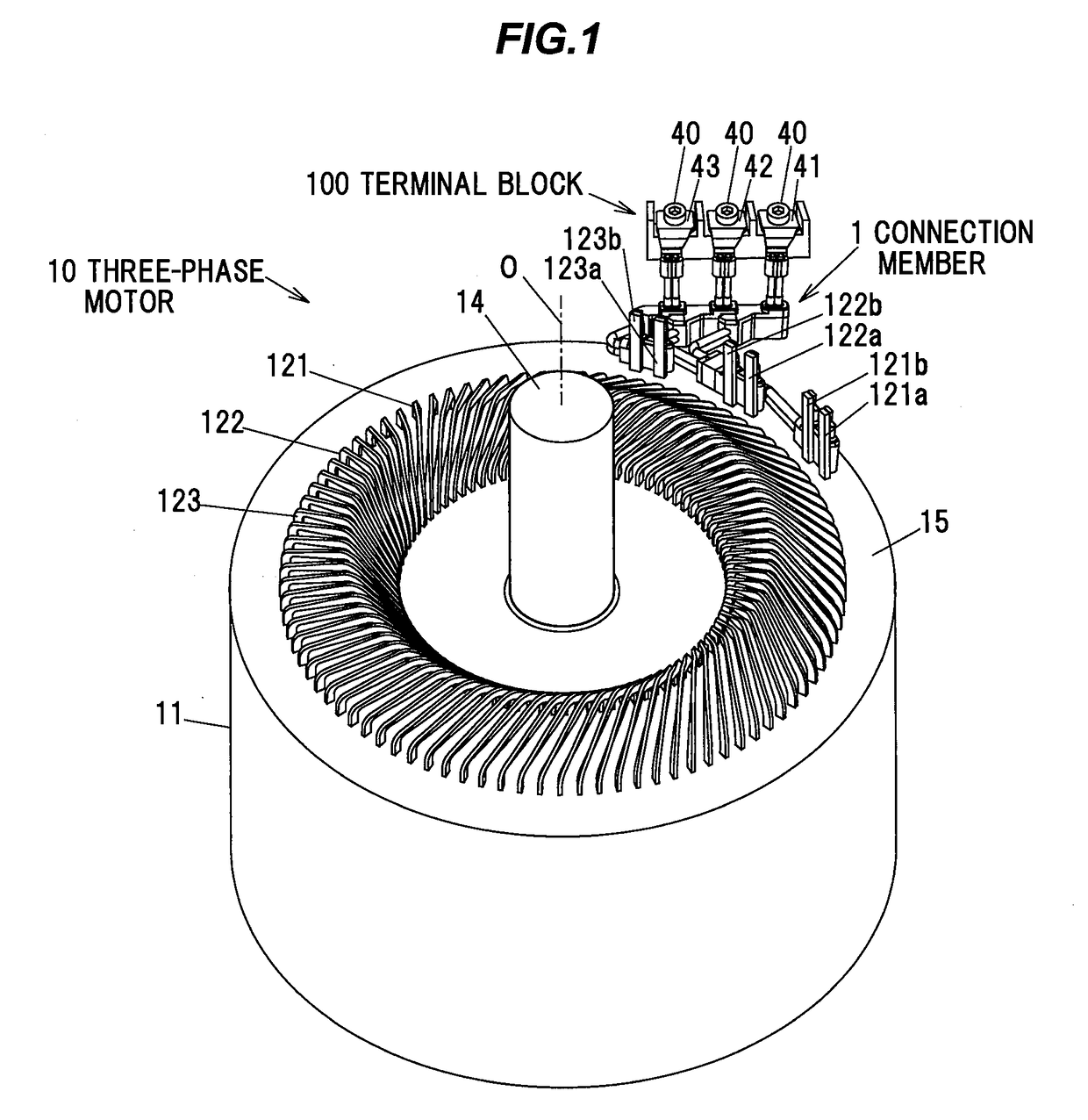

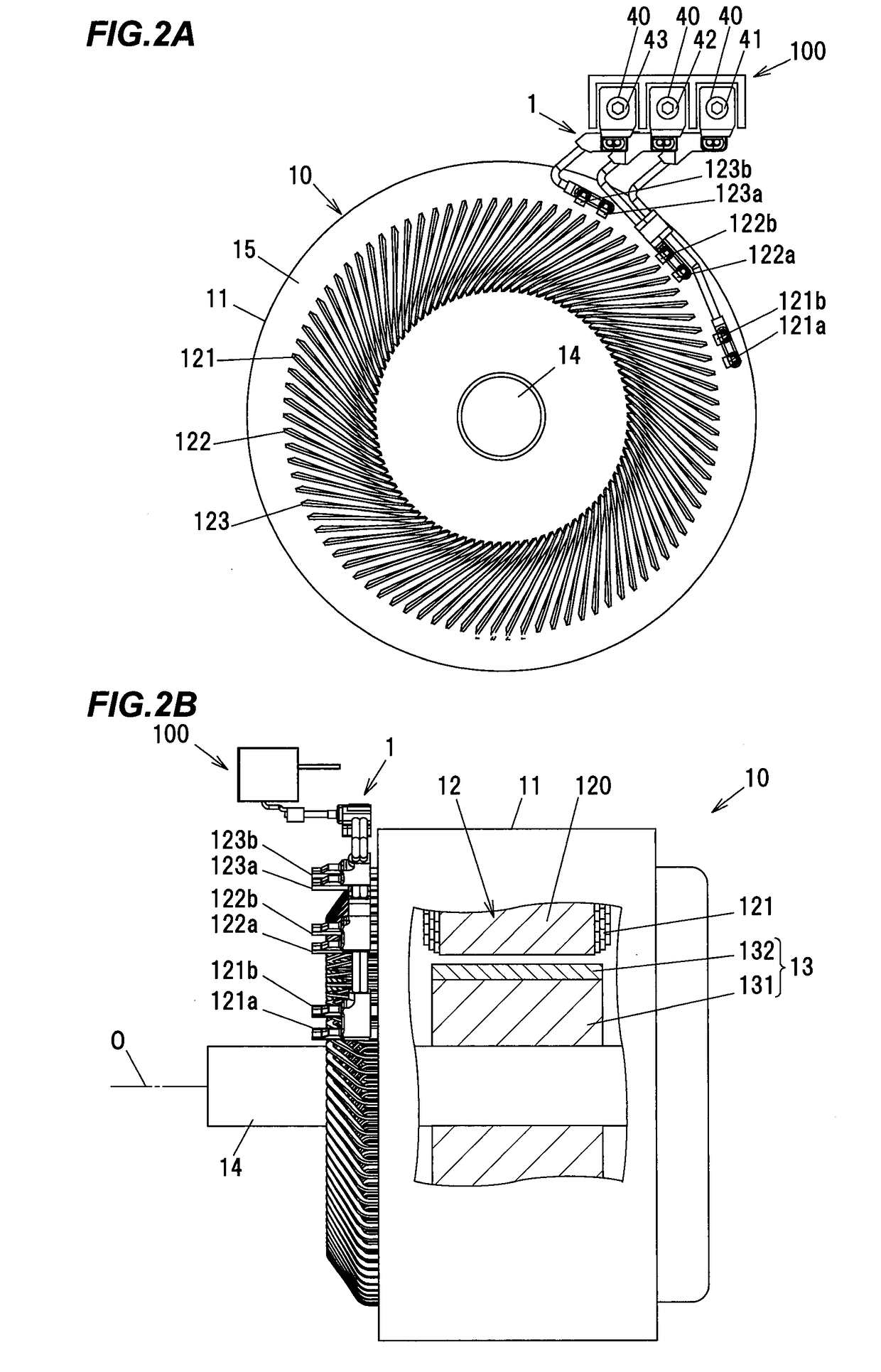

[0028]FIG. 1 is a perspective view showing a rotating electrical machine connection component 1 in an embodiment of the invention and a three-phase motor 10 as a rotating electrical machine which is supplied with an electric current through the rotating electrical machine connection component 1. FIG. 2A is a plan view showing the rotating electrical machine connection component 1 and the three-phase motor 10 and FIG. 2B is a side view showing the rotating electrical machine connection component 1 and the three-phase motor 10. In FIG. 2B, a portion of the three-phase motor 10 is cutaway to show the internal structure.

[0029]The three-phase motor 10 is mounted as a drive source on a vehicle and is supplied with three-phase AC currents from an inverted (not shown) via a terminal block 100 and the rotating electrical machine connection component 1. Hereinafter, the rotating electrical machine connection component 1 is simply referred as “connection component 1”.

[0030]The three-phase moto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap