Anti-regurgitation composition maintaining gut motility

a technology of composition and gut motility, applied in the field of medicine and human nutrition, can solve the problems of not being able to support and compensate for the pressure exerted by the gastric contents, burns or even ulcerative lesions of the esophagus, and complicating the falling asleep of the child, so as to maintain the gut motility of the child, improve the comfort of the child, and improve the effect of diet treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Formulation

[0202]The formulation of milks intended for infant feeding is most often strictly restricted by legislation setting composition standards. Depending on the countries, there may be differences of appreciation notably because of local specificities in the practice of food diversification or else minor modifications of the nutritional optima resulting from locally conducted investigations or studies. Under these conditions, the present example does not intend to represent the diversity of the thickened milk formulations according to the invention.

[0203]Conventionally, in order to meet the nutritional needs of infants, infant milks comprise about 10-15% of proteins, about 25% of lipids and about 50-65% of carbohydrates as well as minerals, vitamins and optionally growth factors. Other ingredients such as one or several prebiotics and / or probiotics may moreover be added to infant milks.

[0204]A non-limiting example of a composition of the anti-regurgitation and / or anti-reflux i...

example 2

Process for Manufacturing a Pasteurized Infant Milk as a Powder Comprising i) Cold-soluble Carob and ii) at Least Two Pectins of Different Natures

[0207]The infant milk base comprising 37% of dry extract is prepared by mixing water heated beforehand to 70° C. with the different infant milk ingredients (said ingredients comprising proteins or amino acids+cold-soluble carob+weakly esterified pectins or weakly esterified and amidated pectins+highly esterified pectins+carbohydrates+minerals+plant fats+vitamins+growth factors). The carob and pectins are incorporated into the infant milk base maintained with stirring in order to obtain their complete dissolution. The whole is maintained at 70° C. with stirring in a double-walled chamber until the homogenization step. The infant milk base then undergoes dual effect homogenization at 200 / 40 bars, i.e., a first homogenization step is carried out under a pressure of 200 bars and a second homogenization step is carried out under a pressure of 4...

example 3

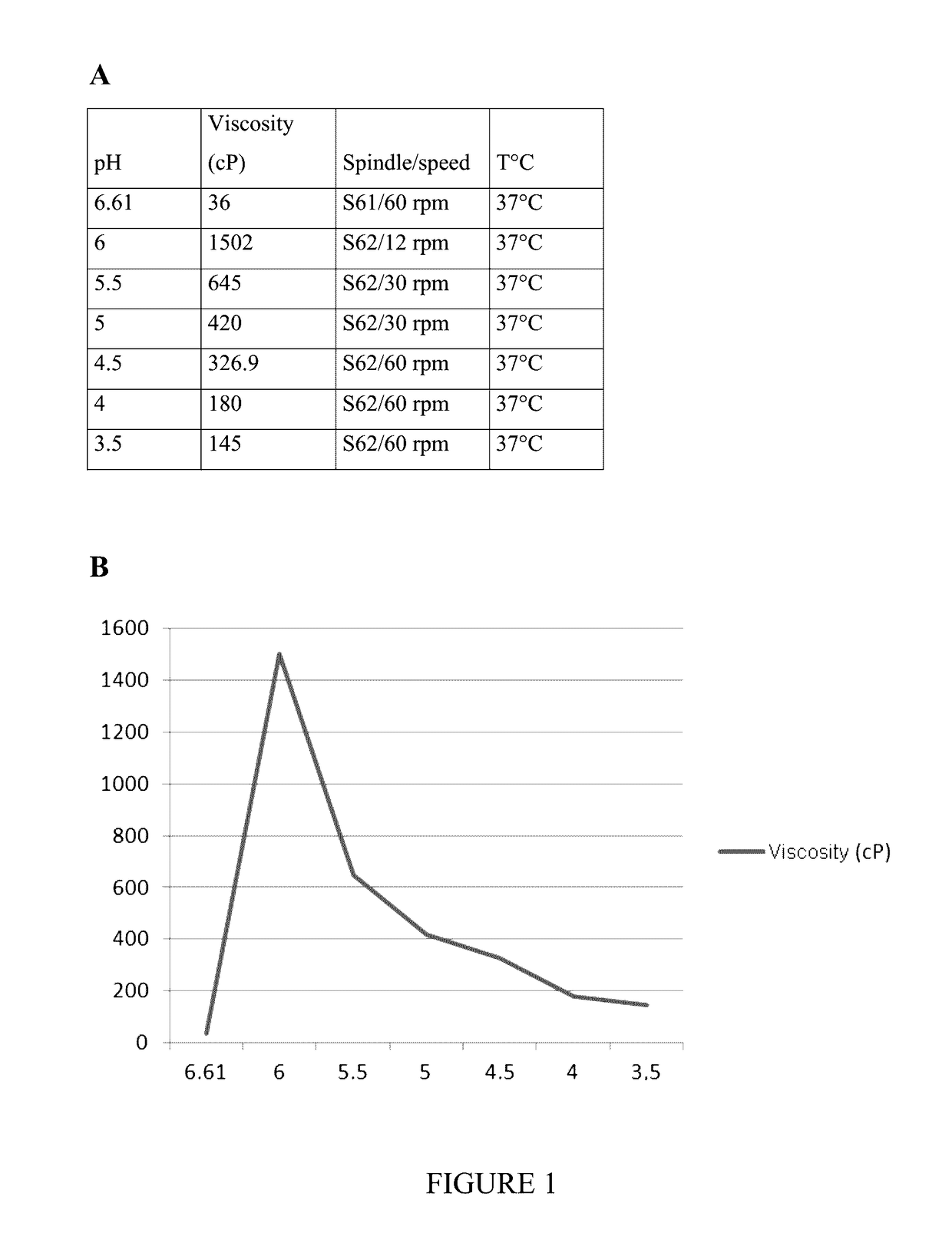

Comparison Between the Viscosity of a Reconstituted Milk Comprising a Milk in Powder Form According to the Invention with the Viscosity of a Conventional AR Milk Containing Starch (Novalac AR®)

[0211]An infant milk according to the invention is produced and collected as a powder according to the manufacturing process mentioned in Example 2. This milk according to the invention thus comprises 4.25% of weakly esterified pectins and weakly esterified and amidated pectins, 1% of highly esterified pectins and 0.5% of cold-soluble carob.

Method and Tools

[0212]The liquid infant milk is then prepared, by dilution of the infant milk as a powder according to the invention in hot water (at 60° C.) with 13% of dry extract. Said liquid infant milk is then cooled to 37° C.

[0213]The conventional AR milk based on starch is also prepared by diluting the powder in water (also at 37° C.) with 13% of dry extract.

[0214]The viscosities of both products are then measured by means of a Brookfield viscosimete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com