Frame structure for a basket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

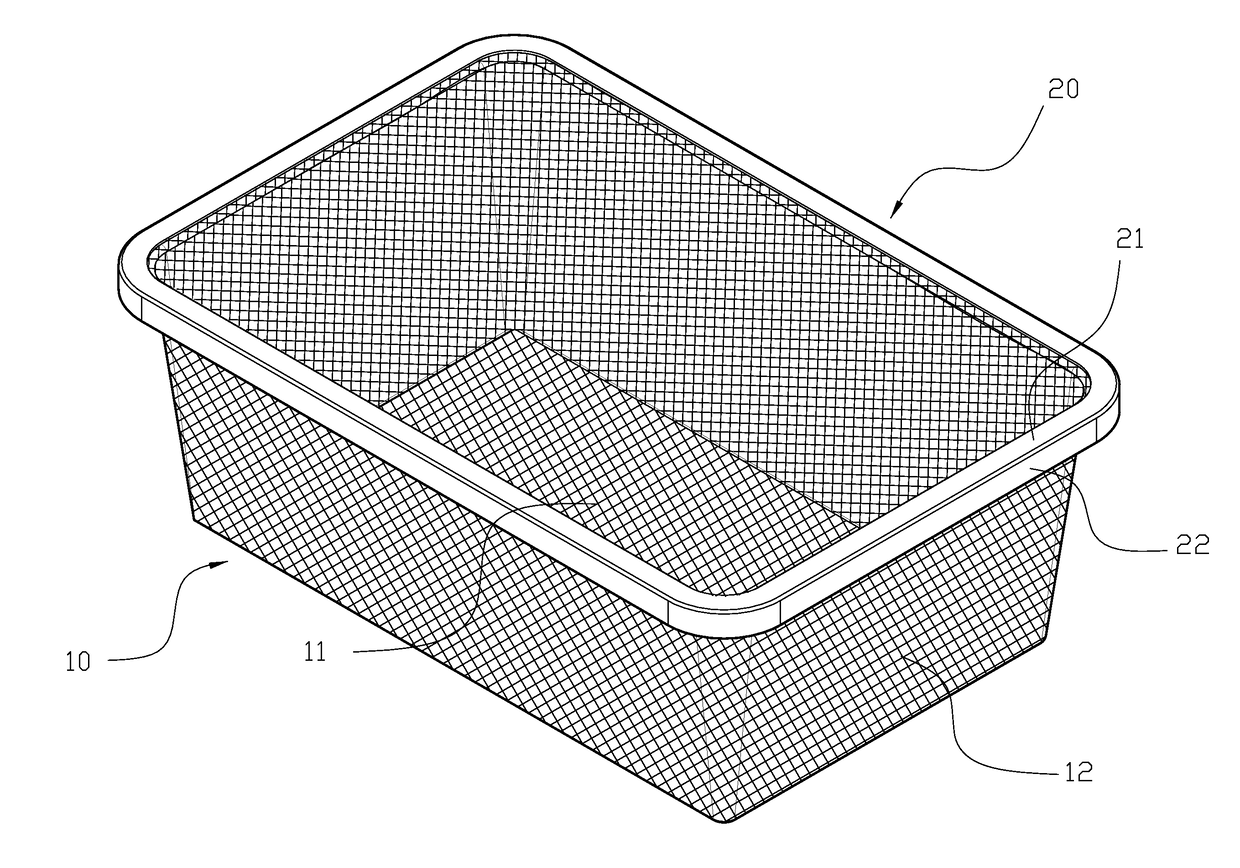

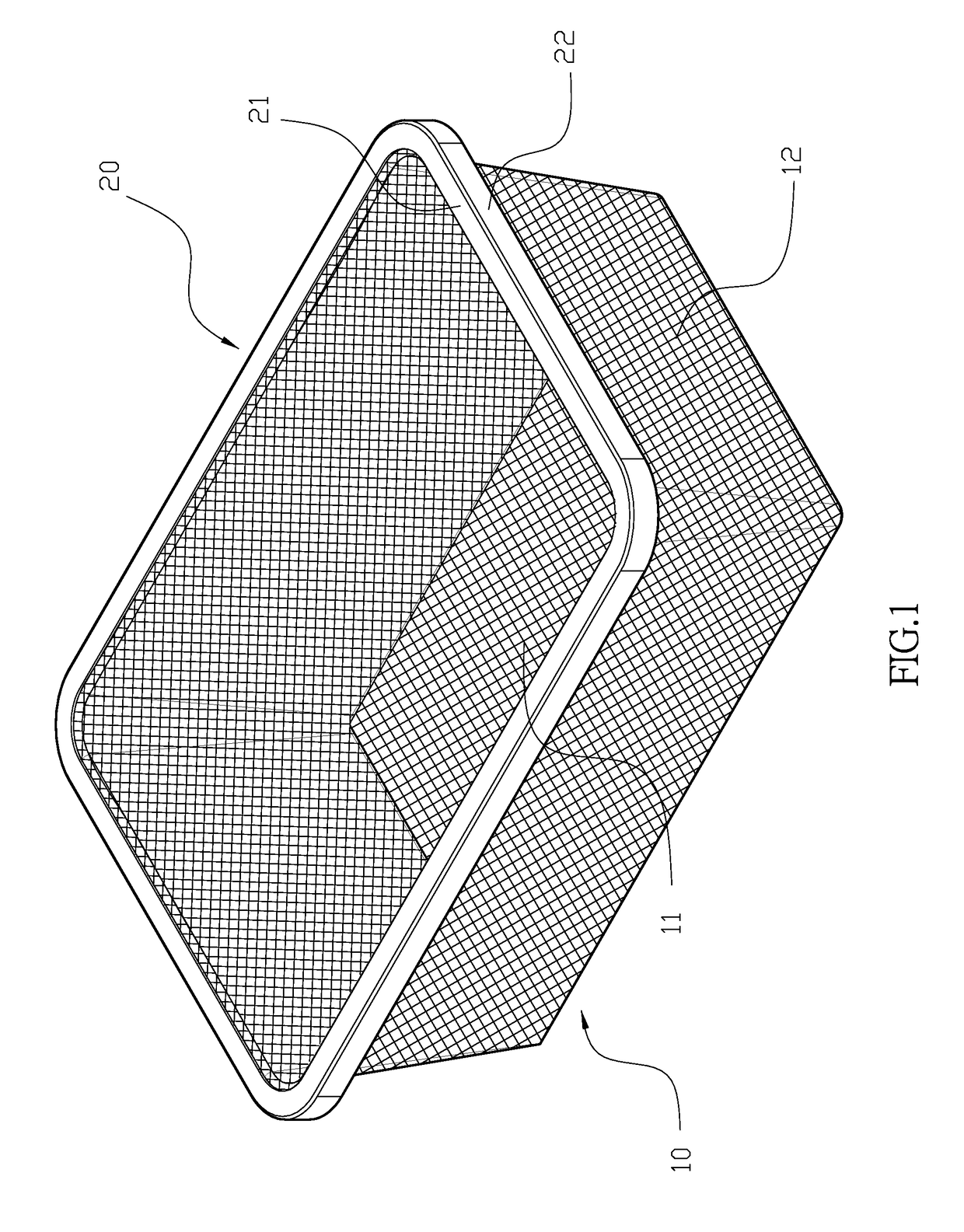

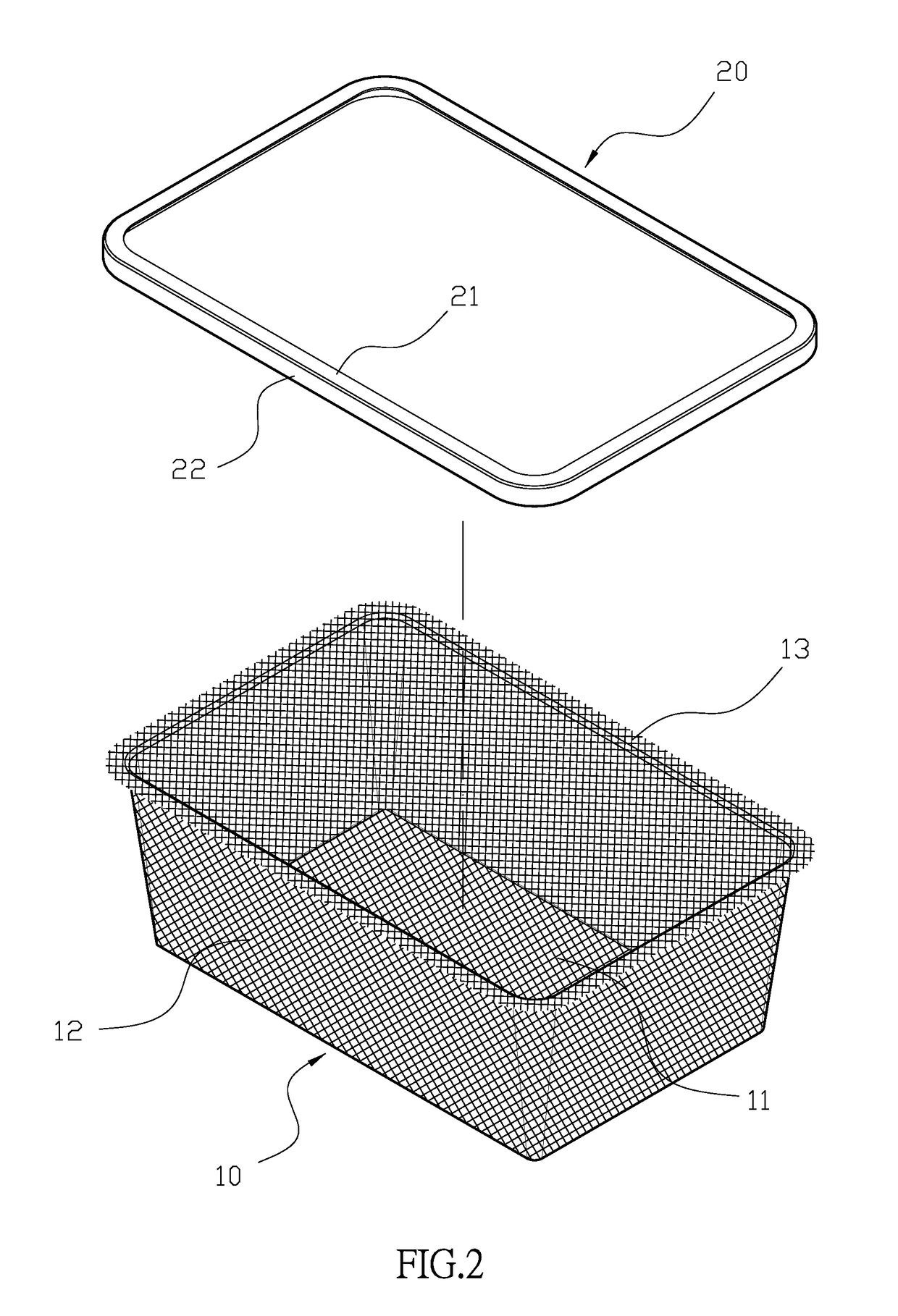

[0021]For a second embodiment of the present invention, please refer to FIG. 5. A frame structure for a basket comprises: a woven basket body 10 and a frame portion 20. The frame portion 20 has a looped shape corresponding to the integrating portion 13 of the woven basket body 10 and comprises a connecting inner edge 21 corresponding to an inner side of the frame portion 20 and an outer edge 22 corresponding to an outer side of the frame portion 20. Furthermore, an enhancing inner edge 23 is provided at an inner side of the connecting inner edge 21, and a substantially 90° angle is formed between the outer edge 22 and the connecting inner edge 21 such that the frame portion 20 has an asymmetric U-shaped cross section. The frame portion 20 utilizes the connecting inner edge 21 to secure onto the integrating portion 13 of the woven basket body 10 and the enhancing inner edge 23 to secure onto to an inner side of the sidewall portion 12 such that the outer edge 22 of the frame portion ...

Example

[0022]For a third embodiment of the present invention, please refer to FIG. 6. A frame structure for a basket comprises: a woven basket body 10 and a frame portion 20. The frame portion 20 has a looped shape corresponding to the integrating portion 13 of the woven basket body 10 and comprises a connecting inner edge 21 corresponding to an inner side of the frame portion 20 and an outer edge 22 corresponding to an outer side of the frame portion 20. Furthermore, a curved portion 24 is disposed between the connecting inner edge 21 and the outer edge 22 such that the frame portion 20 has a U-shaped cross section. The frame portion 20 utilizes the curved portion 24 to cover the integrating portion 13 of woven basket body 10, the frame portion, also utilizes the connecting inner edge 21 to secure onto to an inner side of the sidewall portion of the woven basket body 10, such that the outer edge 22 of the frame portion 20 is adjacent to an outer edge of the sidewall portion 12 and slidabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap