Wind turbine and method for ice removal in wind turbines

a wind turbine and wind turbine technology, applied in the direction of engine control parameters, active/predictive/anticipative control, input signal generation, etc., can solve the problems of aerodynamic loss in certain parts of the blade, inadequate operation in terms of production and load, increase in wind turbine loads and vibrations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

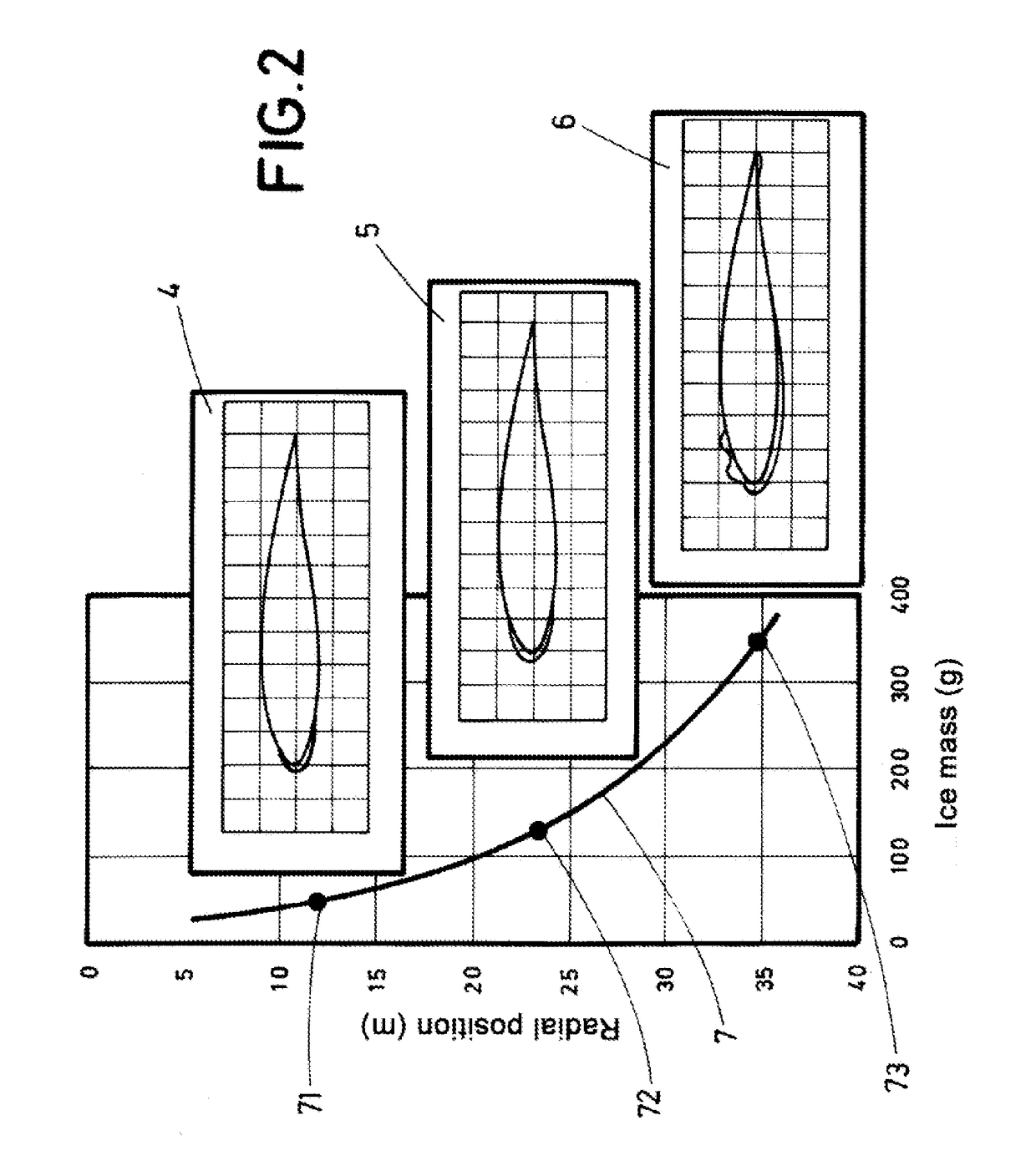

[0007]The present invention discloses a wind turbine that solves the problems of the prior art allowing the removal of ice from the blades with less energy consumption than the devices of the prior art. Also, it does not require substantial modifications in the structural design of the blades.

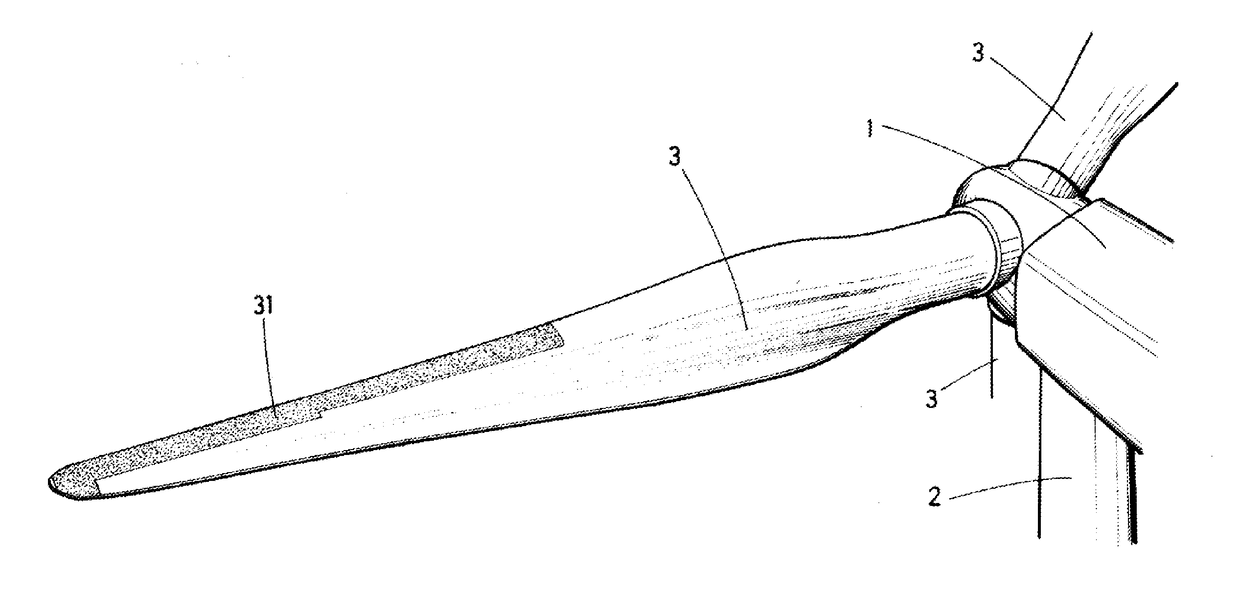

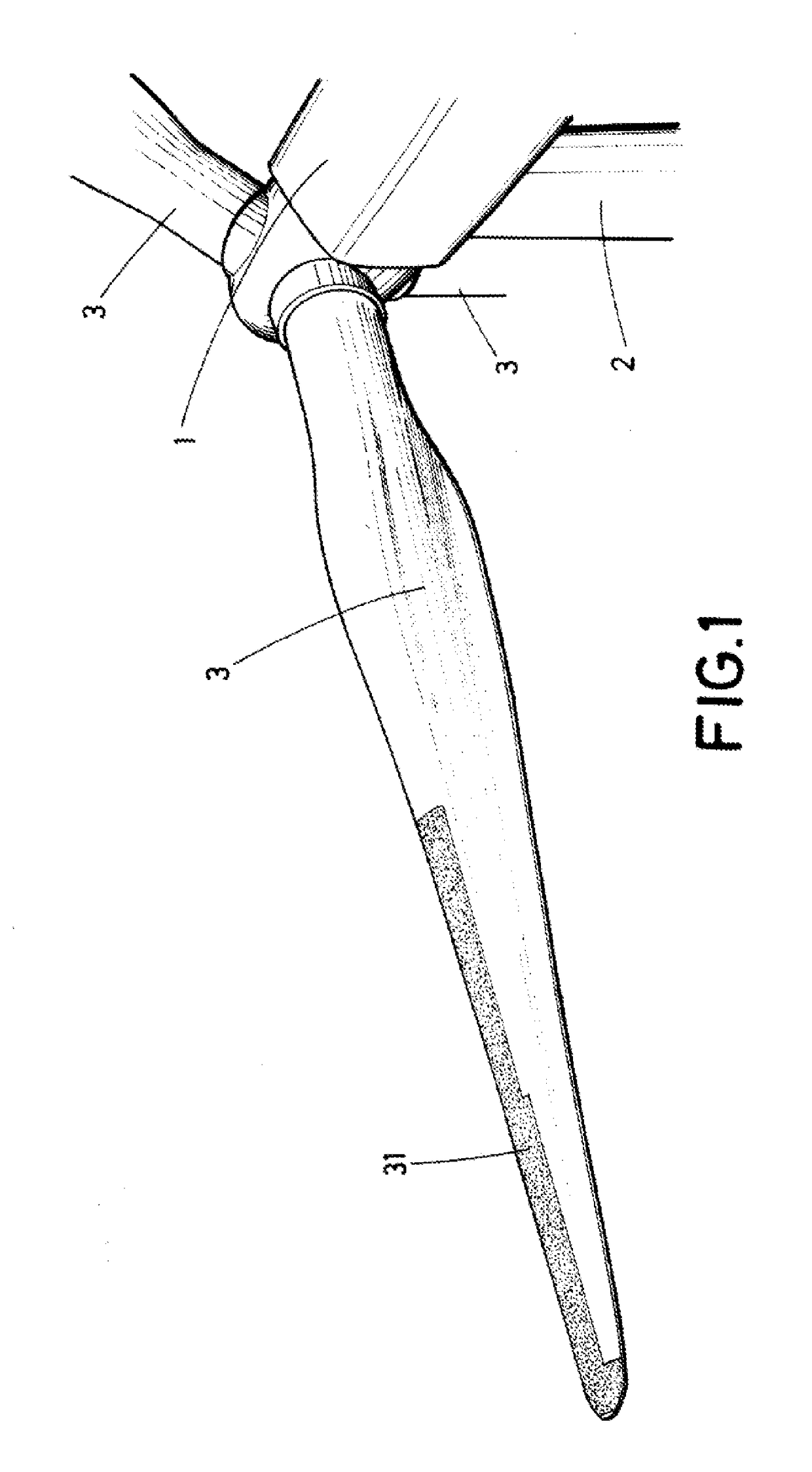

[0008]Specifically, the present invention discloses a wind turbine of the type comprising:[0009]a rotor having at least two blades;[0010]a control system;[0011]means for detecting the presence of ice on the blades;[0012]a heating system having at least one heating element configured to carry out a heating stage of at least one of the blades.

[0013]Preferably, the heating system is connected to the control system and is configured to carry out a heating stage of at least one of the blades by activating the power supply of at least one heating element disposed in each of the blades. To this purpose, the control system comprises at least one ice removal routine that comprises the following stages:[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com