System and method for side insertion of a bicondylar mini knee implant

a technology of bicondylar and knee implants, which is applied in the field of resurfacing prosthesis, can solve the problems of high failure rate of unicondylar implants, large soft tissue disruption, and large scarring of major anatomical structures, and achieves improved accuracy and precision in preparation, greater spatial accuracy, and more reliable and reproducible results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

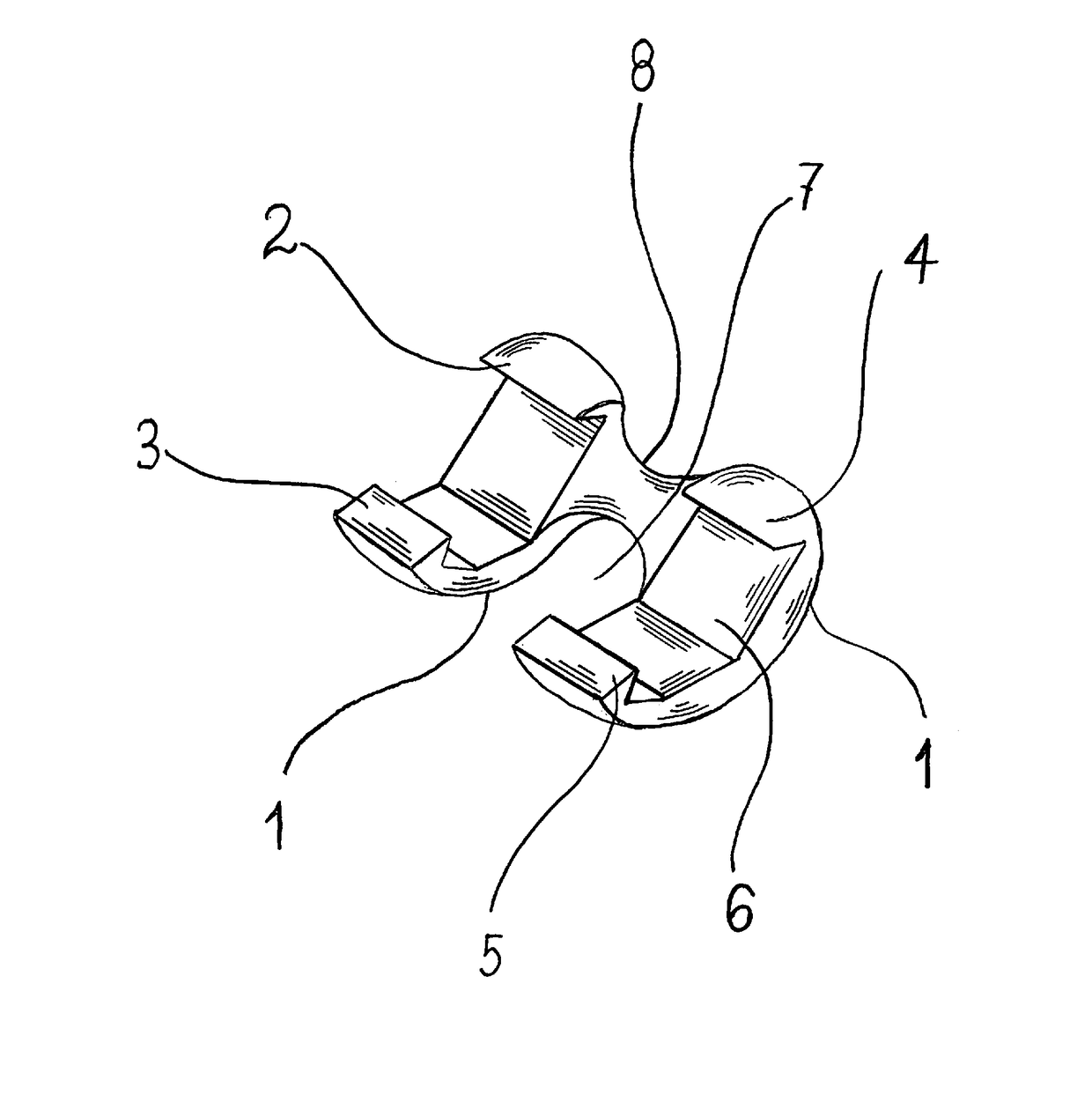

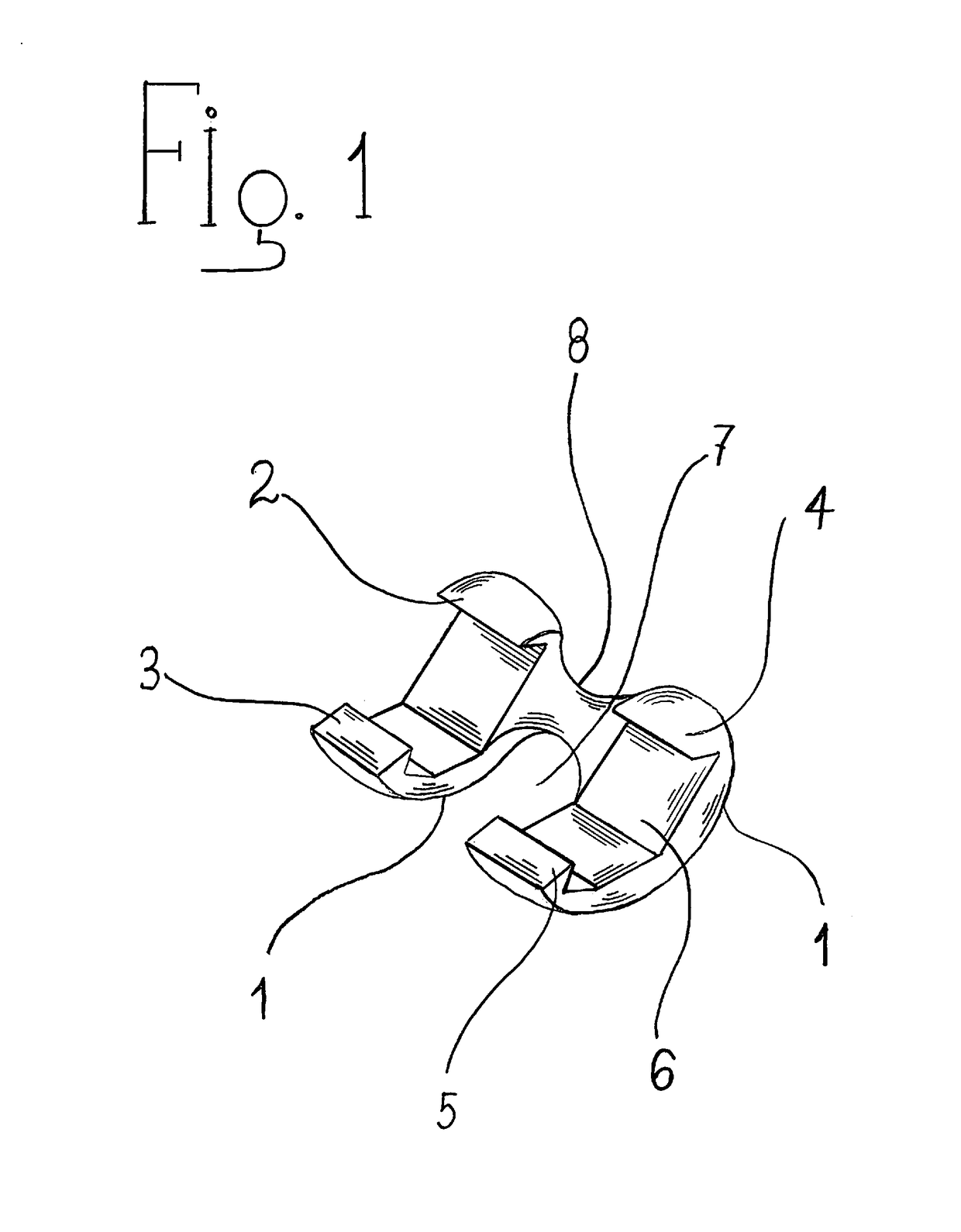

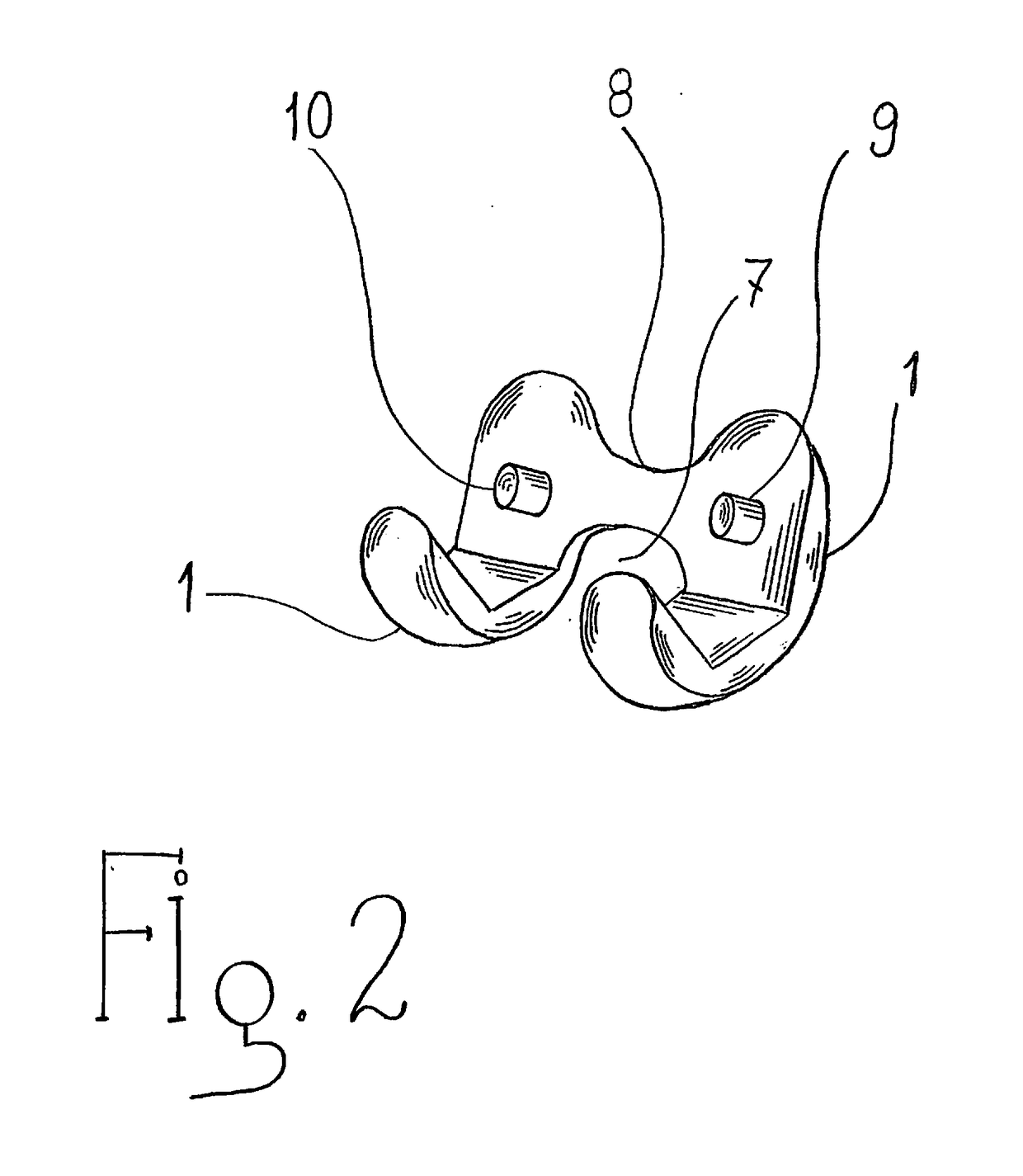

[0062]Turning now descriptively to the drawings, in which similar references characters denote similar element throughout the several views, the attached figures illustrate a concise bicondylar knee resurfacing prosthesis, which comprises a thin metallic femoral arcuate component, a metallic tibial tray and a polyethylene tibial insert. Furthermore, the present invention provides a detailed description of the method to insert the mini bicondylar implant through a small surgical incision made over the lateral aspect of the operated knee away from the patella and without any disruption or damage to the quadriceps muscle or the patellar tendon.

[0063]As opposed to conventional surgical total knee replacement surgery, where the patient lies supine on his back, the surgical technique utilized in the present invention is performed with patient lying on his side on the operative table. The operated knee placed onto a surgical platform 15 firmly attached to the side rails of the operative ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com