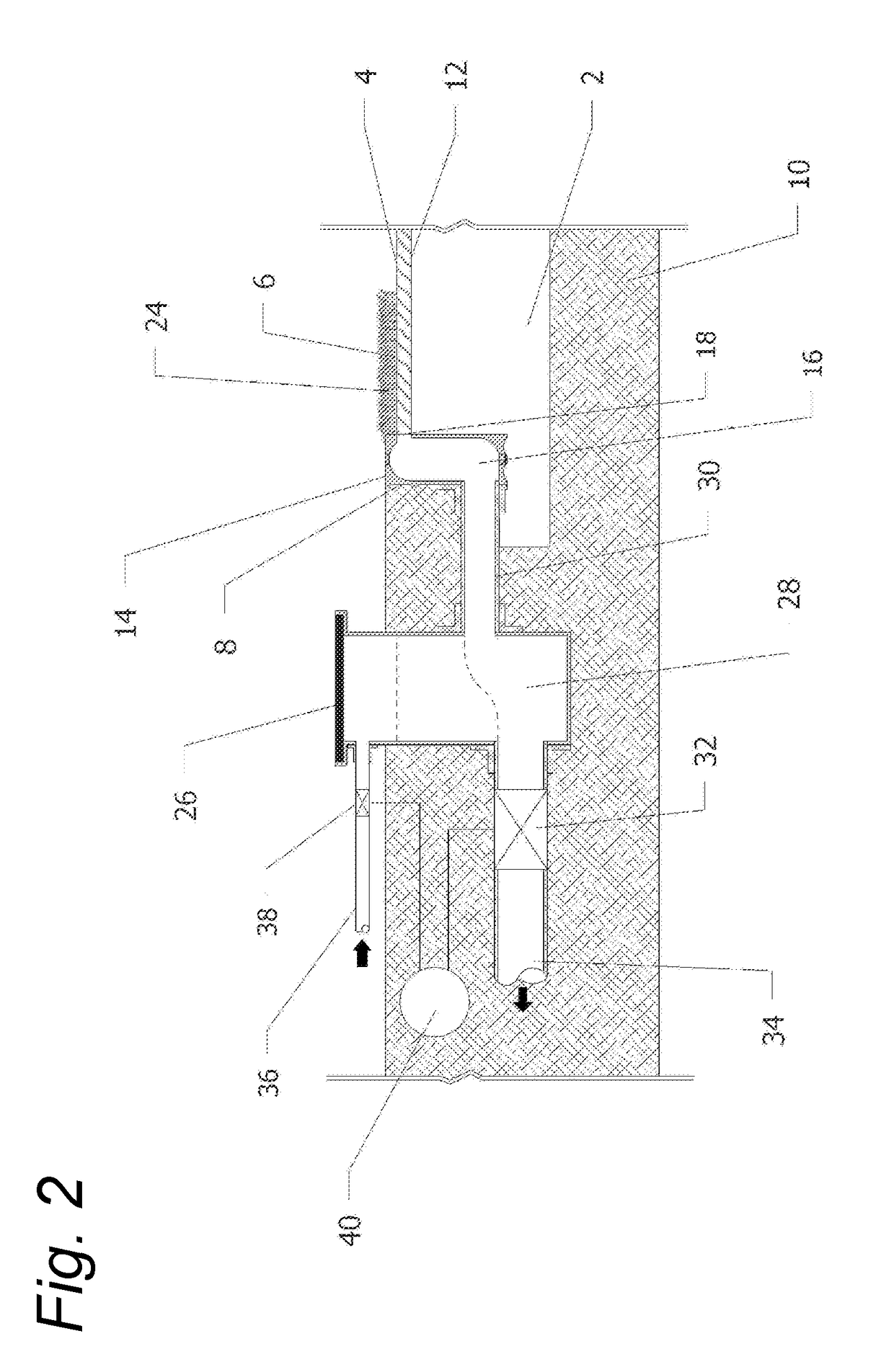

[0045]According to an important advantage of the present invention, the sports field may be formed to be completely level. It will be understood that the bund will generally be completely level, since its upper edge will define the limit to which water may rise without overflowing the bund. Furthermore, the upper surface of the water distributing layer may be substantially horizontal too. In this context, horizontal is intended to denote that it has no appreciable run-off at its surface. It will nevertheless be understood that its absolute level and evenness will be largely dictated by the accuracy and care of placement. In one embodiment the upper surface of the water distributing layer may have no gradient greater than 1 in 100 and optionally less than 1 in 300. It may also exhibit no variation in height of more than 10 mm over a 3 metre straight edge.

[0046]The substrate may also be substantially level. In that case, the thickness of the water distributing layer may be constant over the whole sports field. Producing a level substrate is significantly easier than accurately providing a desired slope in one or more directions. It also simplifies the laying of the following water distributing layer to be horizontal and makes possible the construction of the water distributing layer using pre-fabricated elements.

[0047]In one preferred embodiment of the invention, the water distributing layer comprises recycled plastic granules and a binder. Such a construction is described in WO2012 / 138216, the contents of which is included herein by reference in its entirety, and can conveniently be applied using specialist paving equipment used in sport pitch and running track installation. Preferred granule sizes may range from 0.5-20 mm although granules in the range from 3 mm to 8 mm have given good results. It is also not excluded that flakes, rods, pellets and elongated extrudates may also be used. The binder may be any binder appropriate to the granules used and to the intended use and location. Preferred binders include bitumen, polyurethane or polyolefin based binders and they may be present at between 5% and 40% by weight of the granules, preferably between 15% and 25% and in one embodiment at around 20%. The water distributing layer may also be formed according to the method described in EP1603725, whereby partially melted particles of waste plastic material are welded together to form a porous layer. This method may be particularly applicable to preformed layers although it is not excluded that it may also be used in-situ.

[0048]The water distributing layer may also comprise other components, in particular other granules. In particular, rubber or stone granules may be included at up to 50% by weight or even up to 70% by weight in the final mixture in order to adjust the technical properties of the layer. Furthermore, the water distributing layer may comprise a number of sub-layers having different properties. This may particularly be the case where the uppermost portion of the water distributing layer serves as a performance layer having required shock absorbing and energy restitution values.

[0049]According to the invention, the water distributing layer may be constructed to have a void ratio of between 20% and 70%, optionally around 45%. For an average sized pitch of 7500 m2 and for a water distributing layer having a void content of 45%, a layer thickness of 40 mm equates to 18 lts per m2 or 135,000 lts water storage capacity for the entire pitch, excluding the additional capacity of the drain channel. The void ratio may be adjusted by varying the size and shape of granules or particles forming the layer and by varying the pressure applied during manufacture. The water distributing layer may have a specific density of between 300 Kg / m3 and 700 Kg / m3, preferably between 400 Kg / m3 and 600 Kg / m3 and most preferably around 500 Kg / m3.

[0050]The water distributing layer may be provided to have engineering properties of strength and modulus according to the intended sport or activity. This will also depend on the nature of the artificial turf layer above and any other performance layers. In certain embodiments, the water distributing layer will be effectively rigid, whereby primary shock absorption for the players is provided by performance layers above the water distributing layer. According to one embodiment of the invention, the water distributing layer may have a Young's modulus in compression of greater than 0.1 MPa, alternatively greater than 1 MPa and in an embodiment, greater than 2 MPa. In general, the Young's modulus in compression will be less than 50 MPa, alternatively less than 10 MPa and in an embodiment, less than 5 MPa. In other embodiments, the sports field may further comprise a resilient layer provided between the water distributing layer and the artificial turf layer.

Login to view more

Login to view more  Login to view more

Login to view more