All-secondary air cooled industrial steam condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

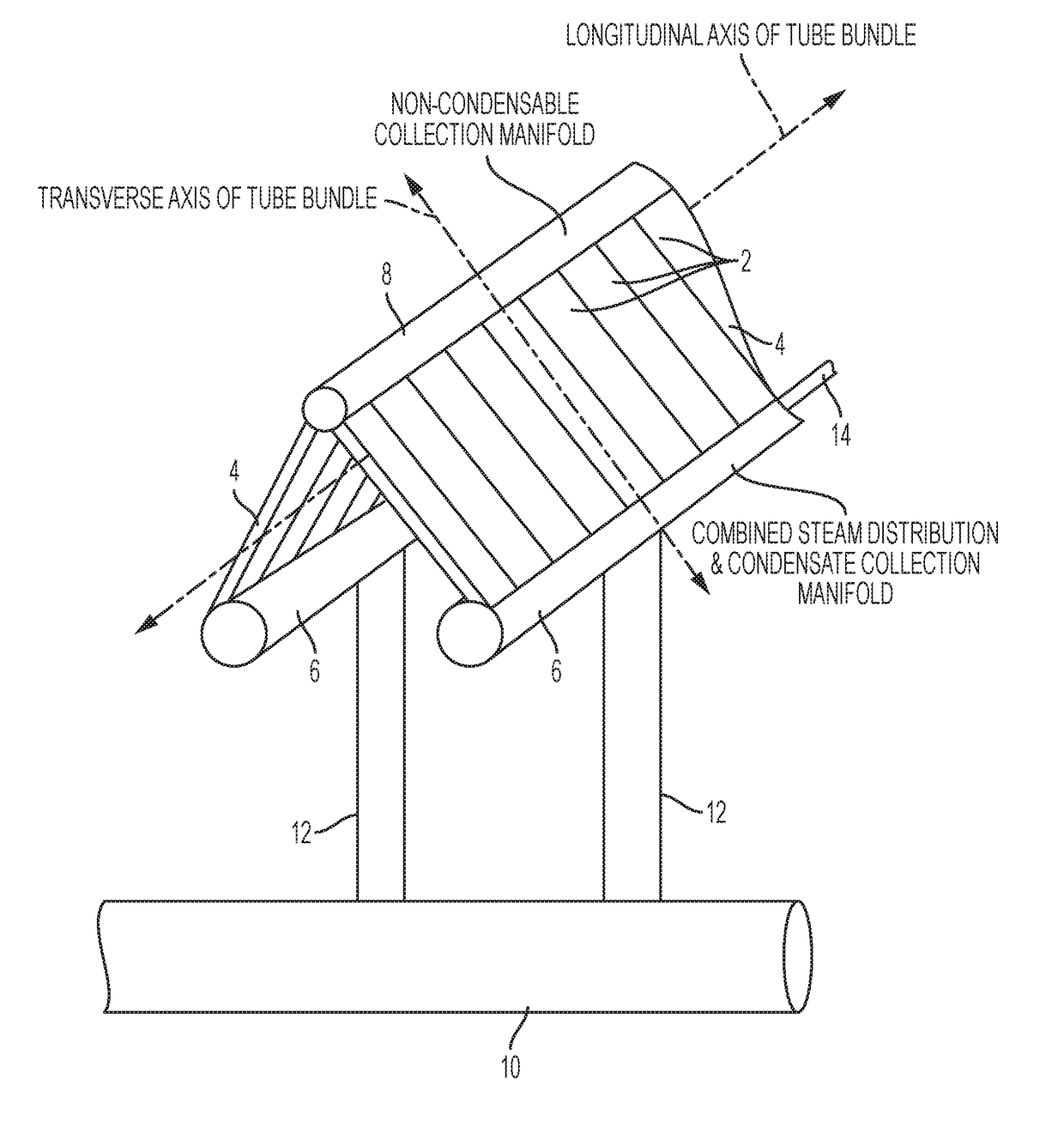

[0042]A-Frame ACC with All Secondary Bundles

[0043]Referring to FIG. 2, tubes 2 are arranged in secondary bundles 4. The longitudinal axes of the tubes 2 are aligned parallel with the transverse axis of the tube bundle, each tube generally oriented 25°-35°, and preferably 30°, from the vertical). Combination steam distribution / condensation collection manifolds 6 are attached at the bottom of each of two secondary bundles 4 that are joined at their top in an A-frame configuration. Steam is distributed to the tubes 2 via the combined steam distribution / condensate collection manifolds 6, and condensate forms in the tubes 2 as the steam condenses and travels down the tubes 2 into the combined steam distribution / condensate collection manifold 6. A single non-condensable collection manifold 8 is attached to the top of both bundles 6 to collect the non-condensable gases that travel to the top of the tubes 2. Steam is supplied to the combined steam distribution / condensate collection manifold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com