Balanced rotary engine

a rotary engine and balance technology, applied in the direction of reciprocating piston engines, machines/engines, positive displacement engines, etc., can solve the problems of few custom-made machines, and achieve the effects of reducing the number of parts, generating significant torque, and reducing the size of the cubicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Definitions

[0121]Unless otherwise specified, the following definitions apply:

[0122]The singular forms “a”, “an” and “the” include corresponding plural references unless the context clearly dictates otherwise.

[0123]As used herein, the term “comprising” is intended to mean that the list of elements following the word “comprising” are required or mandatory but that other elements are optional and may or may not be present.

[0124]As used herein, the term “consisting of” is intended to mean including and limited to whatever follows the phrase “consisting of”. Thus, the phrase “consisting of” indicates that the listed elements are required or mandatory and that no other elements may be present.

1. General Rotary Engine Construction

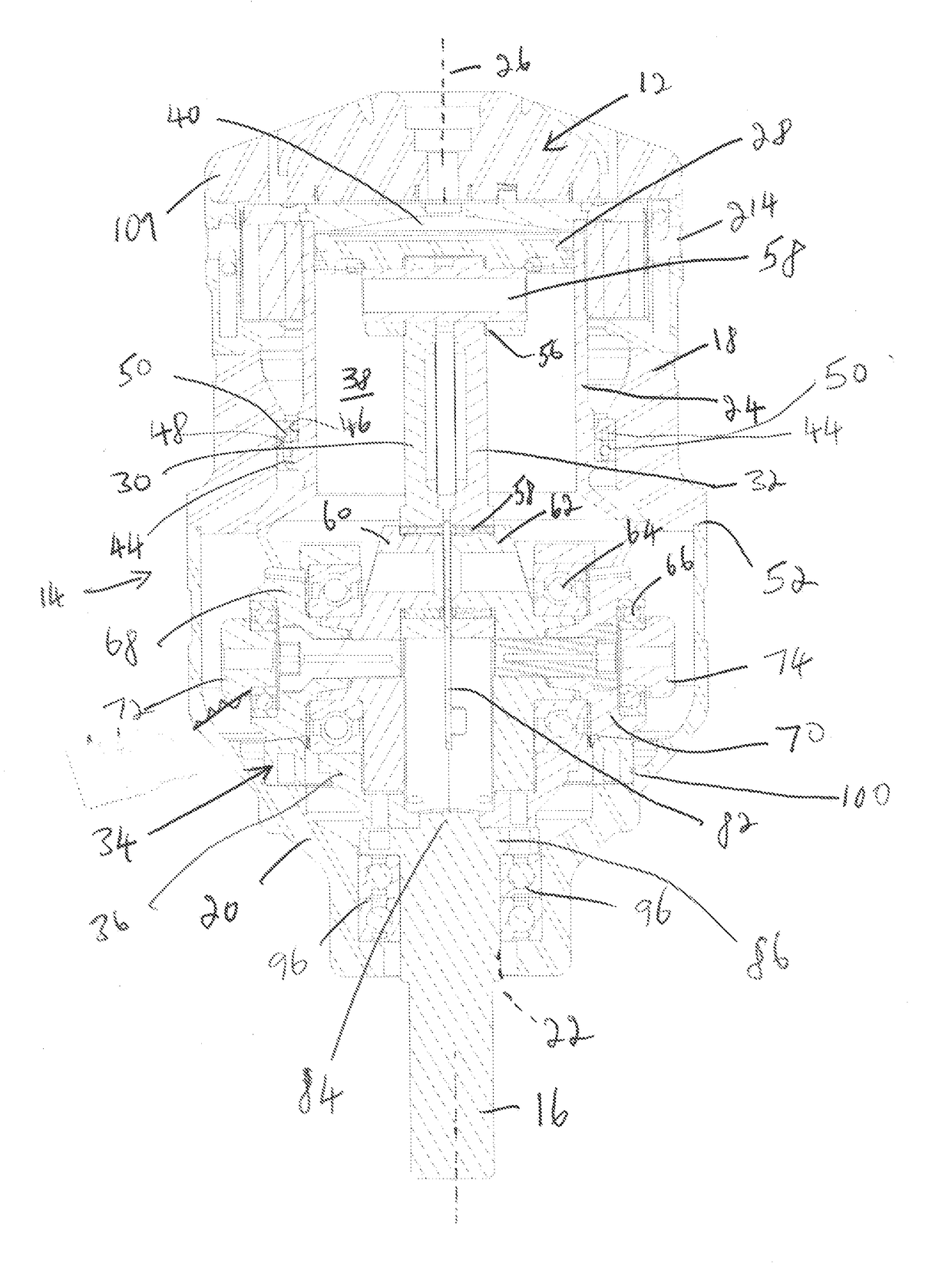

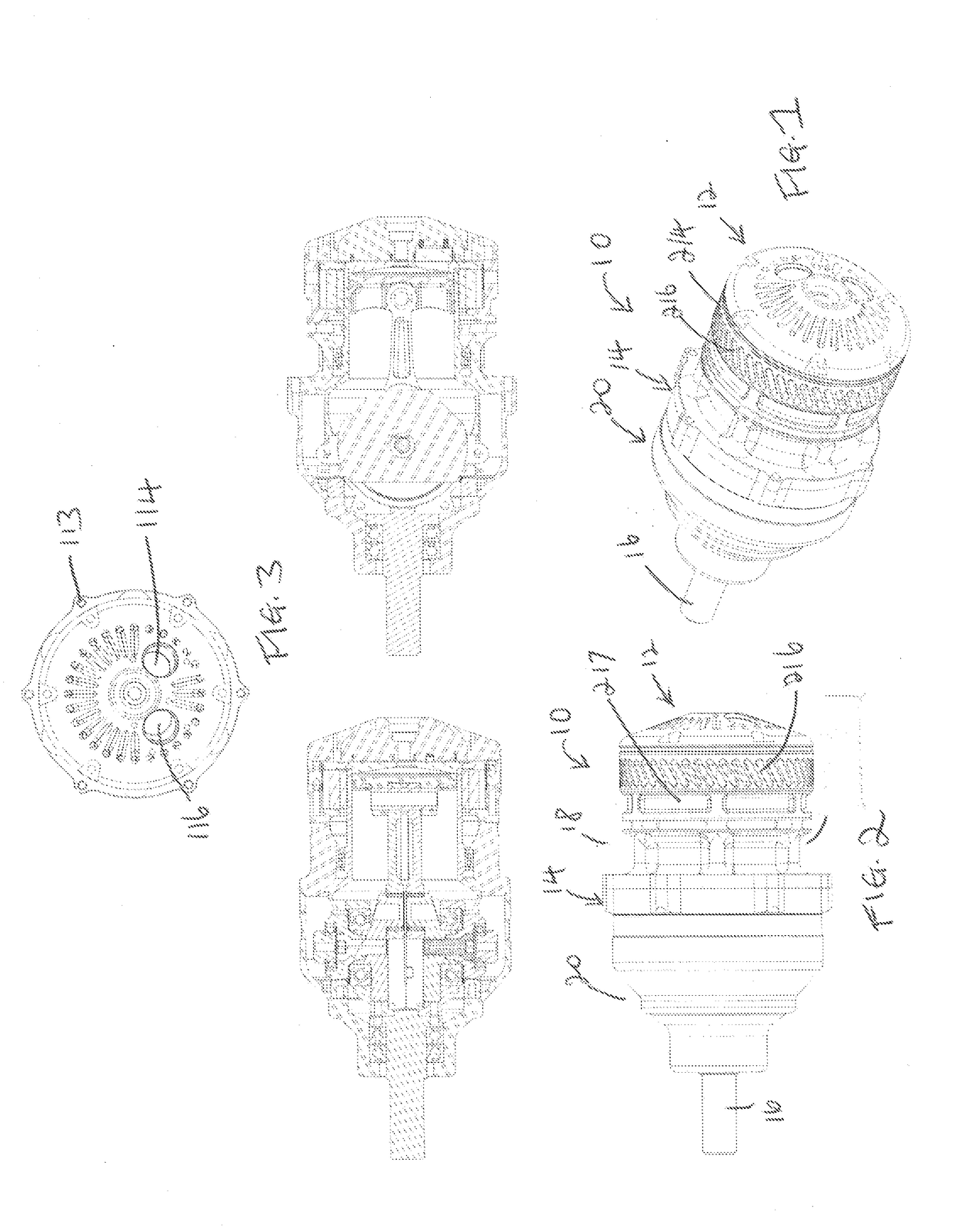

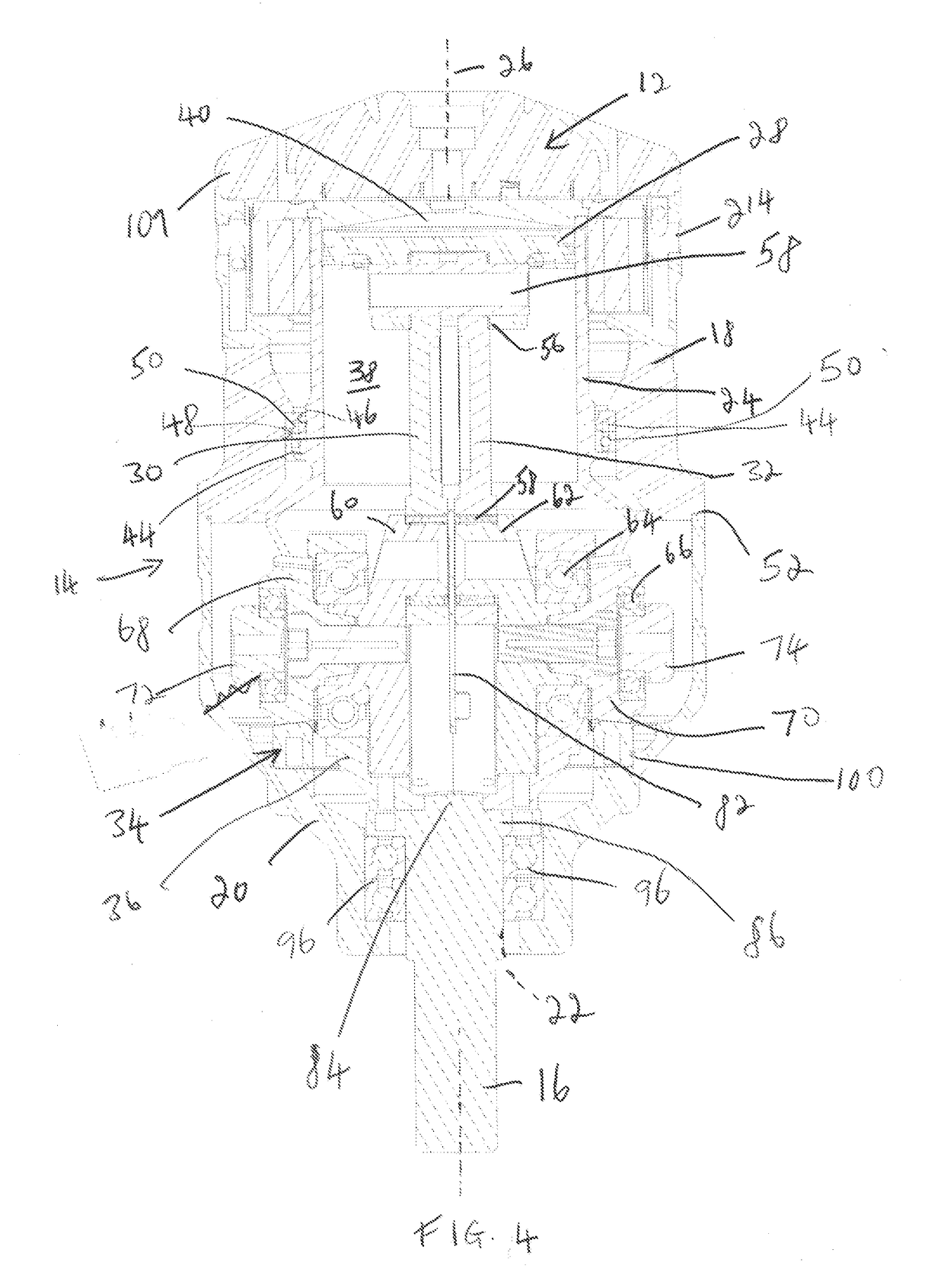

[0125]Referring now to FIGS. 1-11, a balanced rotary engine is shown generally at 10. Broadly speaking, the rotary engine 10 includes a domed cylinder head 12, an outer casing 14, and a drive shaft 16 extending away from the outer casing 14. The outer casing 14 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com