Production of alpha-olefins

a technology of alpha-olefin and alpha-olefin, which is applied in the direction of lyases, polypeptides with his-tags, lubricant compositions, etc., can solve the problems of mixing that may not be desired, and achieve specific decarboxylase activity, facilitate the identification of similar enzymes, and specific decarboxylase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

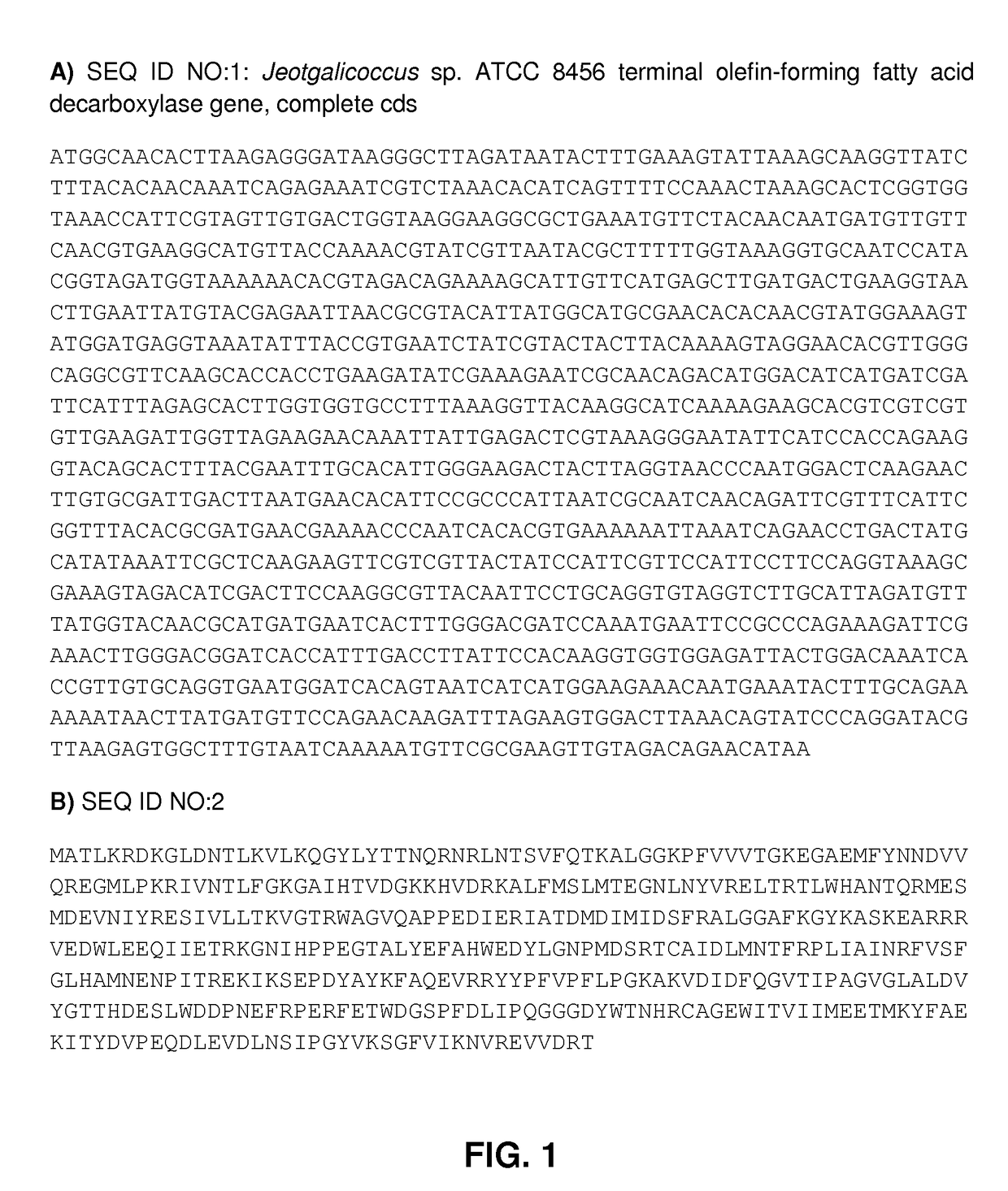

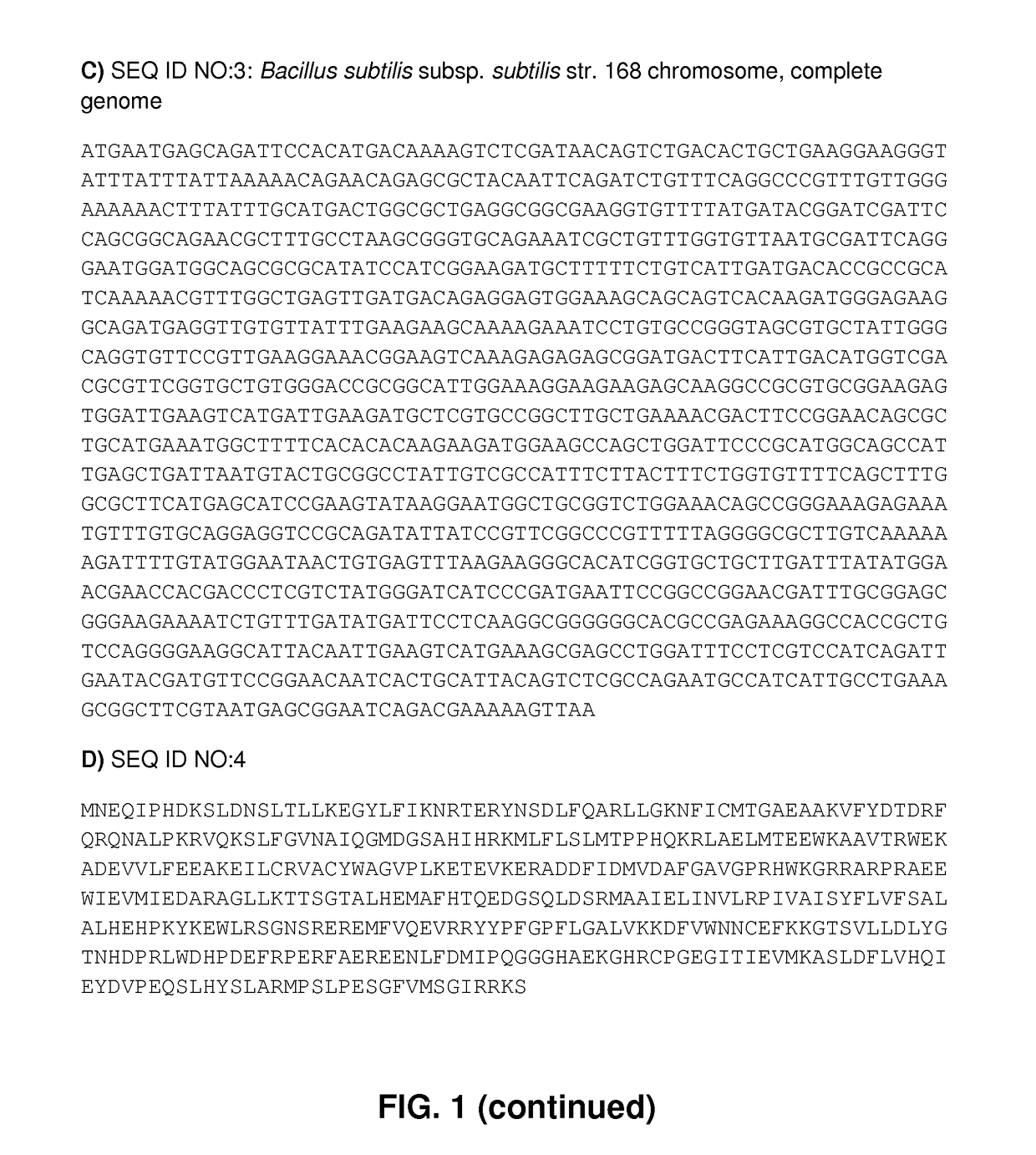

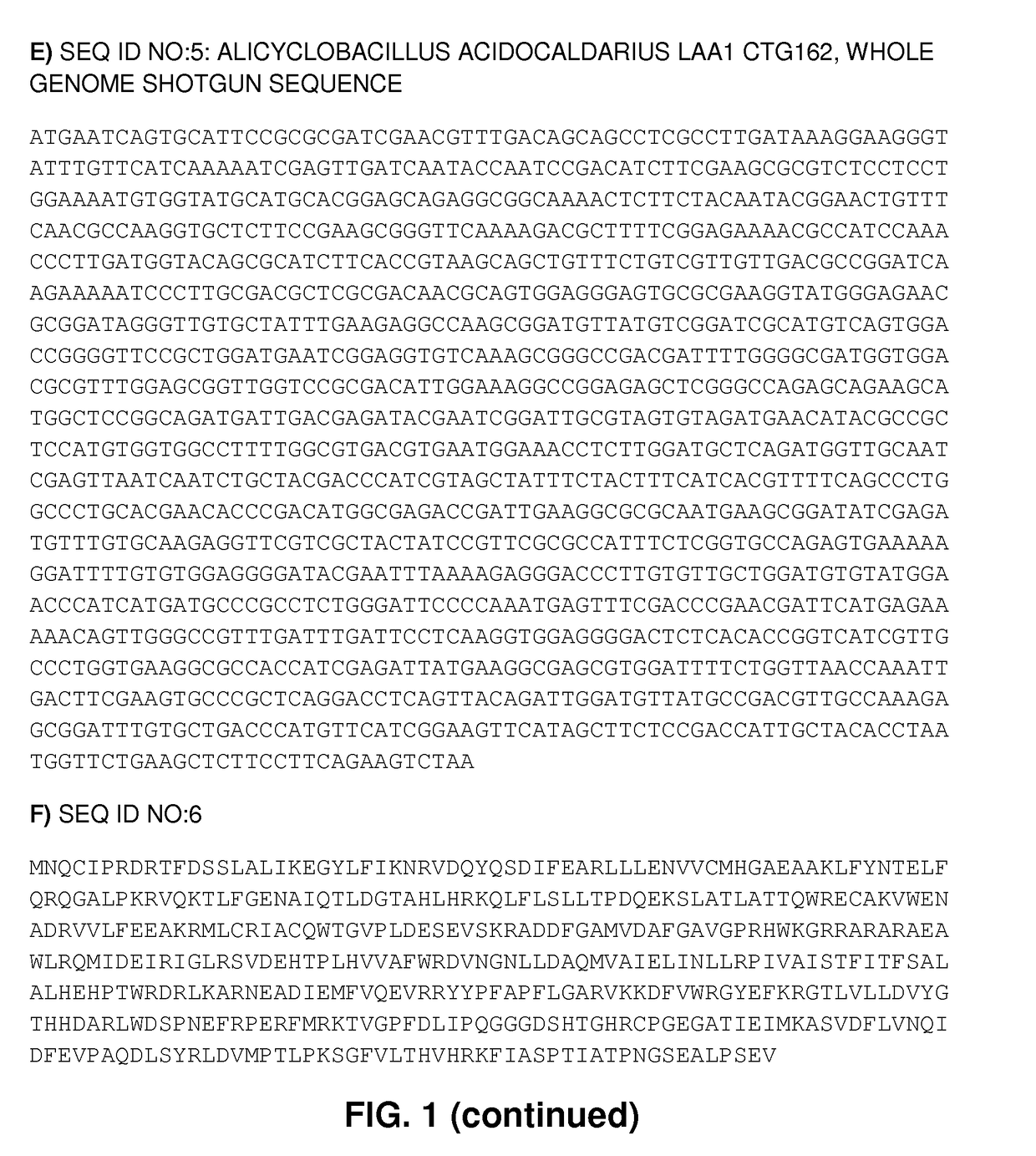

Image

Examples

example 3

n of α-Olefins and Hydroxy Fatty Acids by Sm46-Del29, Bs168 and Aa162

[0170]Recombinantly expressed and purified Bs168 and Aa162 from Example 1 and Sm46-de129 of Example 2 were reacted with C14 fatty acid and the products of decarboxylation (C13 α-olefin) and hydroxylation (α-OH—O14 fatty acid and β-OH—C14 fatty acid) reactions were analyzed.

[0171]All enzymes tested were able to decarboxylate myristic acid (C14), but also catalyzed α- and β-hydroxylation of myristic acid as side reactions. Fatty acid decarboxylation was the dominant reaction for all tested enzymes, but Sm46-del29 formed less hydroxy fatty acids, indicating that these enzymes have specific decarboxylase activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| freezing temperature | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com