Gas heater conversion system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

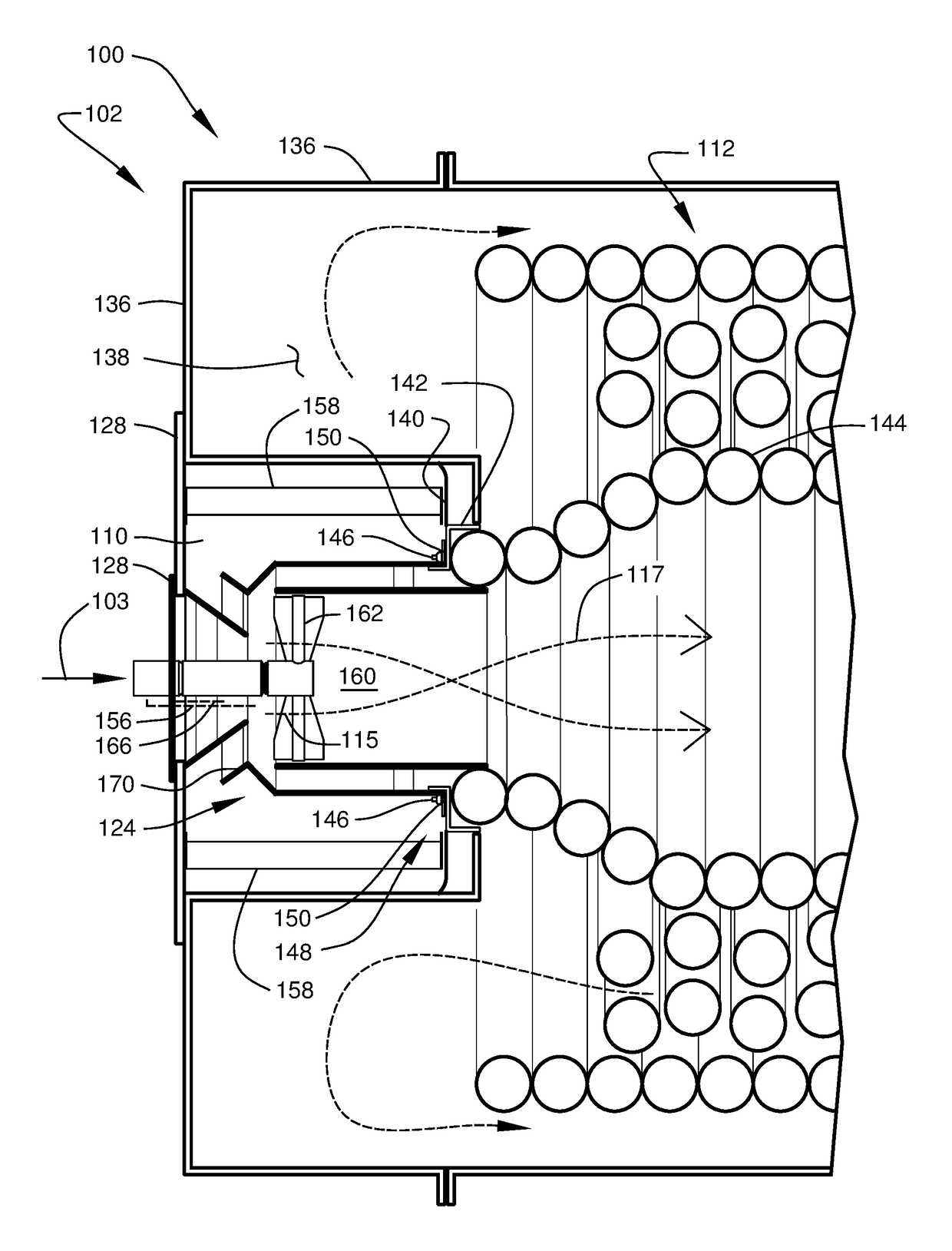

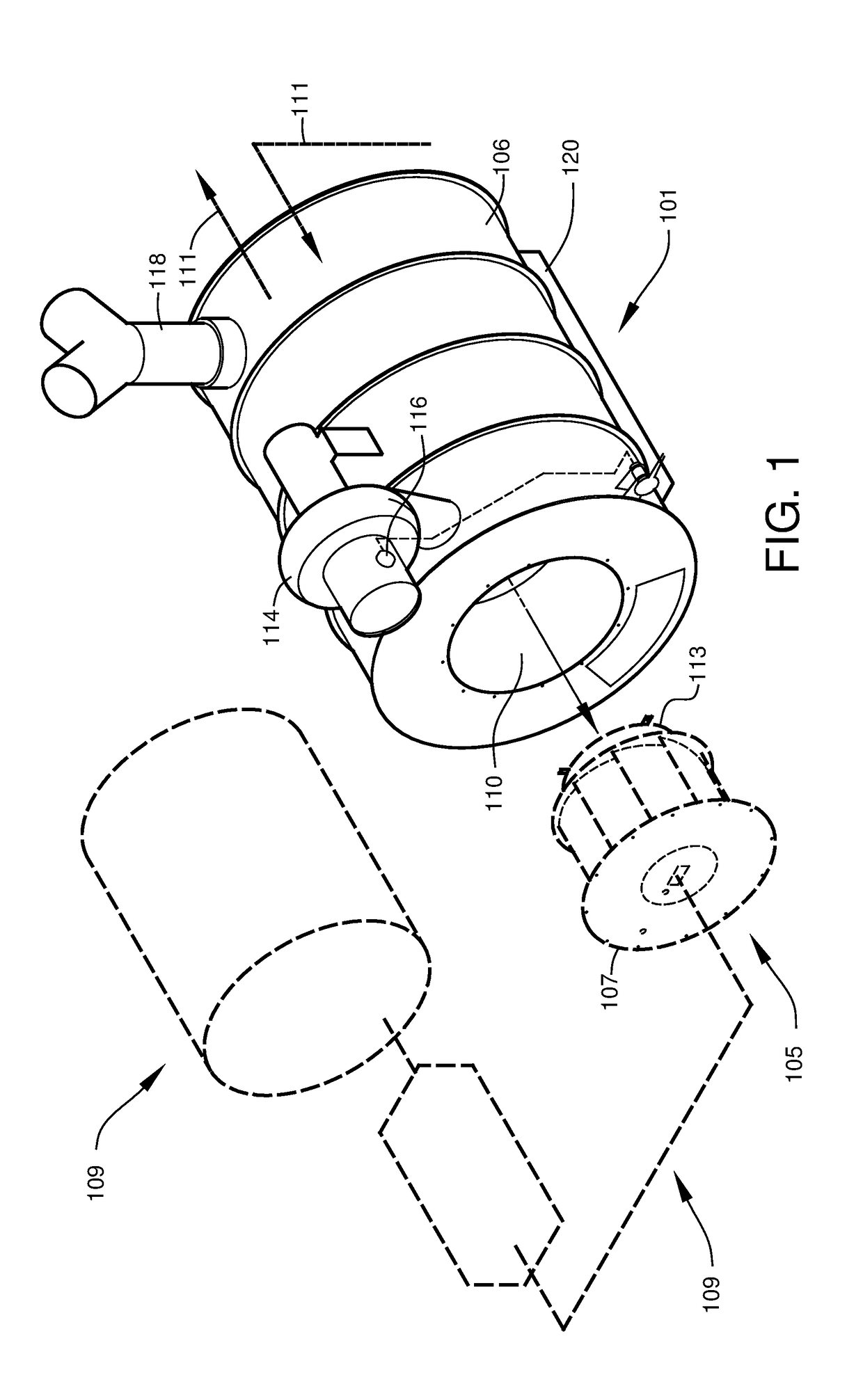

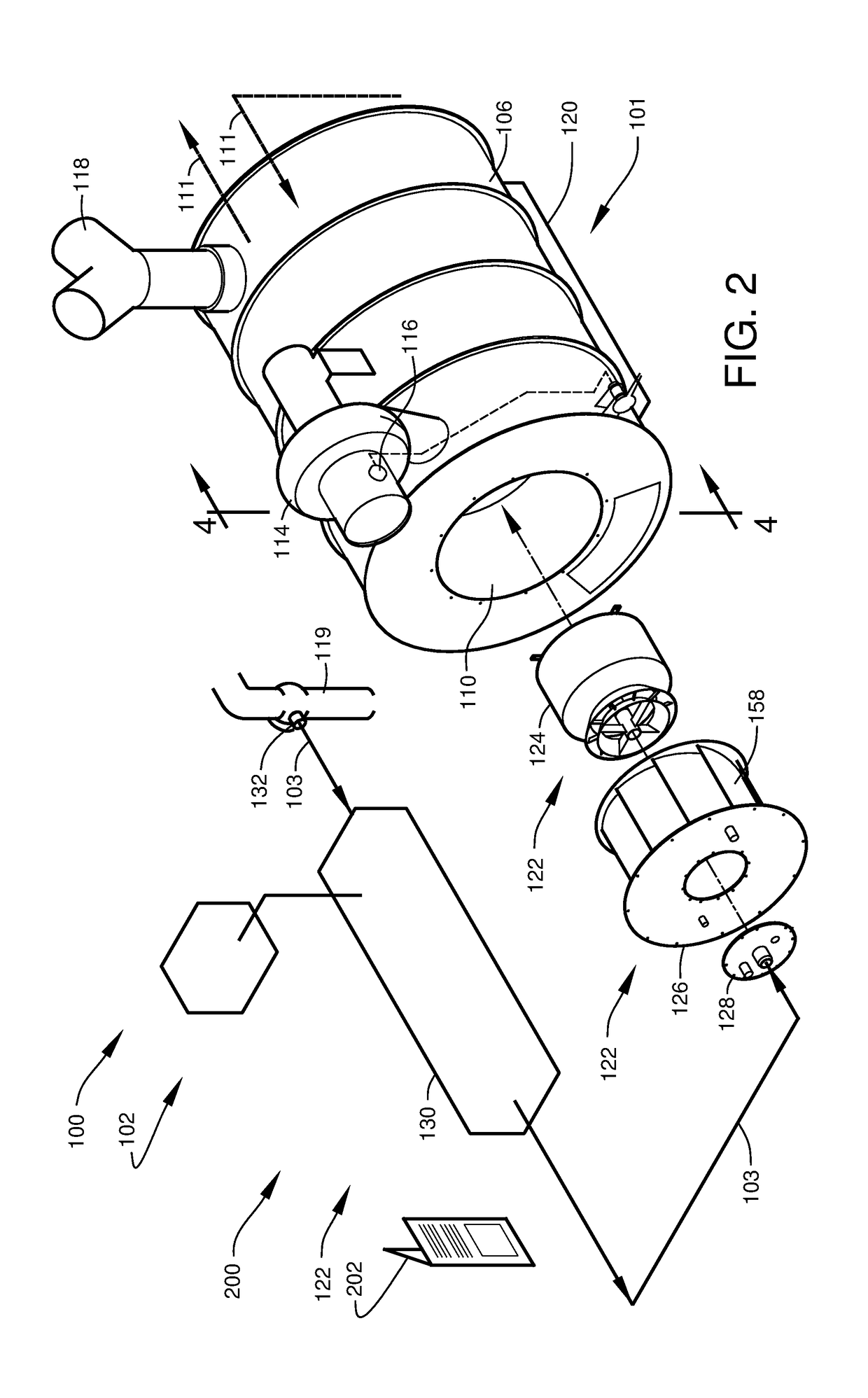

[0028]As discussed above, embodiments of the present disclosure relate to fired industrial heaters and more particularly to a liquid to gaseous fuel conversion system as used to convert a liquid-fuel combustion heater to a combustion heater using at least one gaseous fuel.

[0029]For the last 50 to 60 years, feed-water heaters used in hydraulic fracturing oil recovery have operated on diesel fuel. The current market seeks more economical and emissions friendly equipment. Generally speaking, the presently-disclosed system is arranged to convert diesel-fired industrial-process heaters to operate on natural gas, propane, or other gaseous fuels. This allows operator to retain their existing fired heaters while taking advantage of the more economical and emissions friendly natural gas and related gaseous fuels.

[0030]During performance testing, unmodified diesel-fired units consumed diesel fuel at a rate of about 200 liters per hour. At the time of testing, the cost of diesel fuel averaged ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap