Plate-fin heat exchanger for gas heater

A technology of plate-fin heat exchanger and gas water heater, which is applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc. Heater to strengthen heat exchange and other issues, to achieve the effect of easy processing, remarkable performance, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

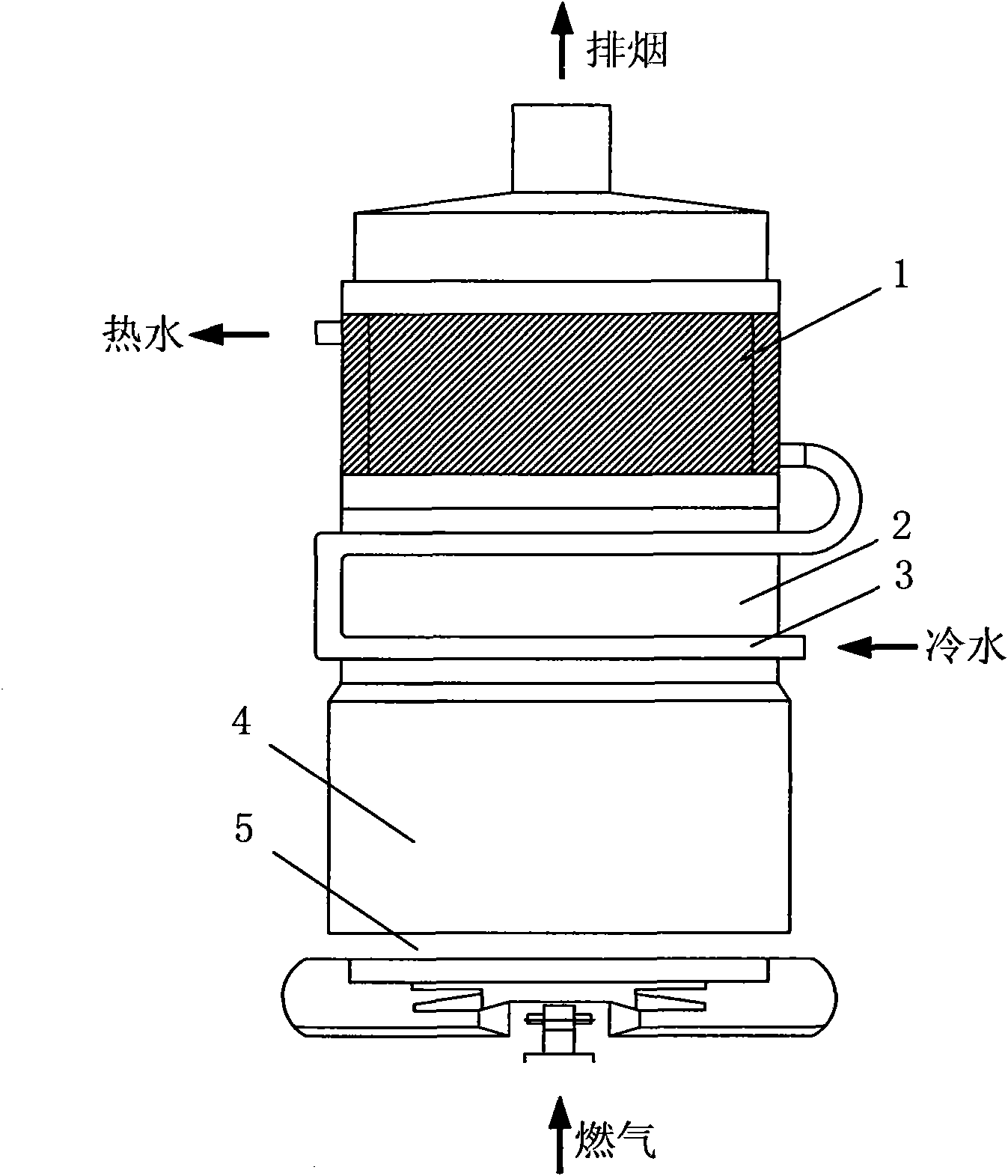

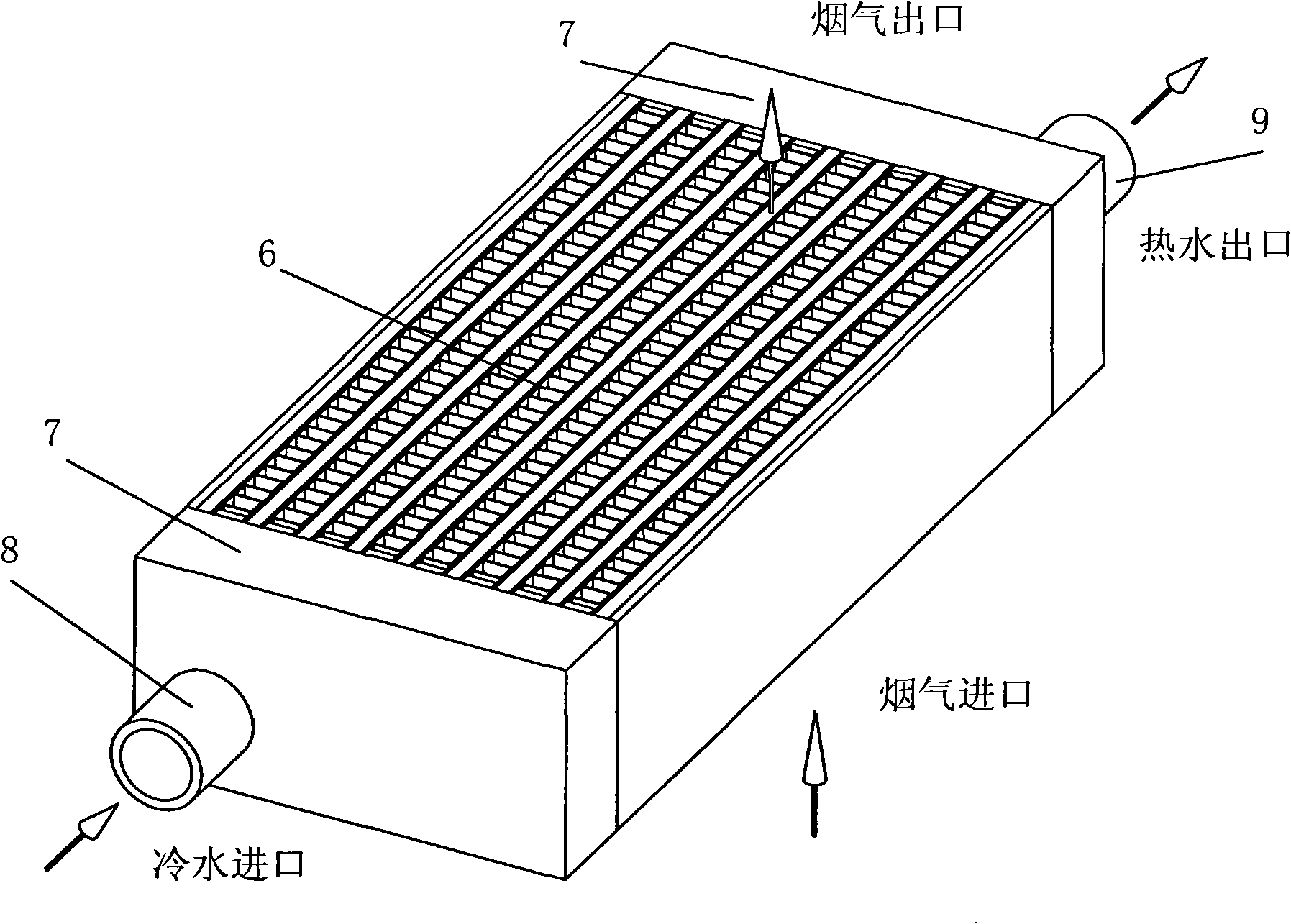

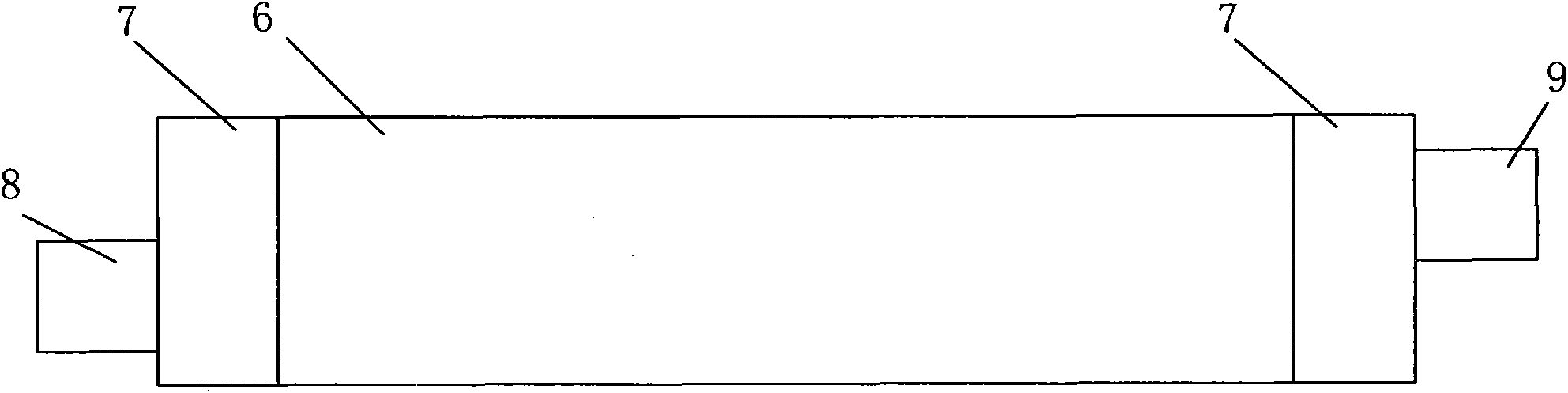

[0024] Such as figure 1 As shown, the heat exchange system of a gas water heater is mainly composed of a plate-fin heat exchanger 1 , a water tank 2 , a heat exchange coil 3 , a combustion chamber 4 and a burner 5 . The plate-fin heat exchanger 1 is the core component of the gas-water heat exchange system of the gas water heater. The plate-fin heat exchanger 1 is connected to the heat exchange coil 3 in the water tank 2, the water tank 2 is connected to the combustion chamber 4, and the burner 5 is arranged at the bottom of the combustion chamber 4. During operation, the high-temperature flue gas generated by the burner 5 enters the plate-fin heat exchanger 1 made of copper-based brazing stainless steel from the bottom through the combustion chamber 4, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com