A blast-retaining panel wall and connectors thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

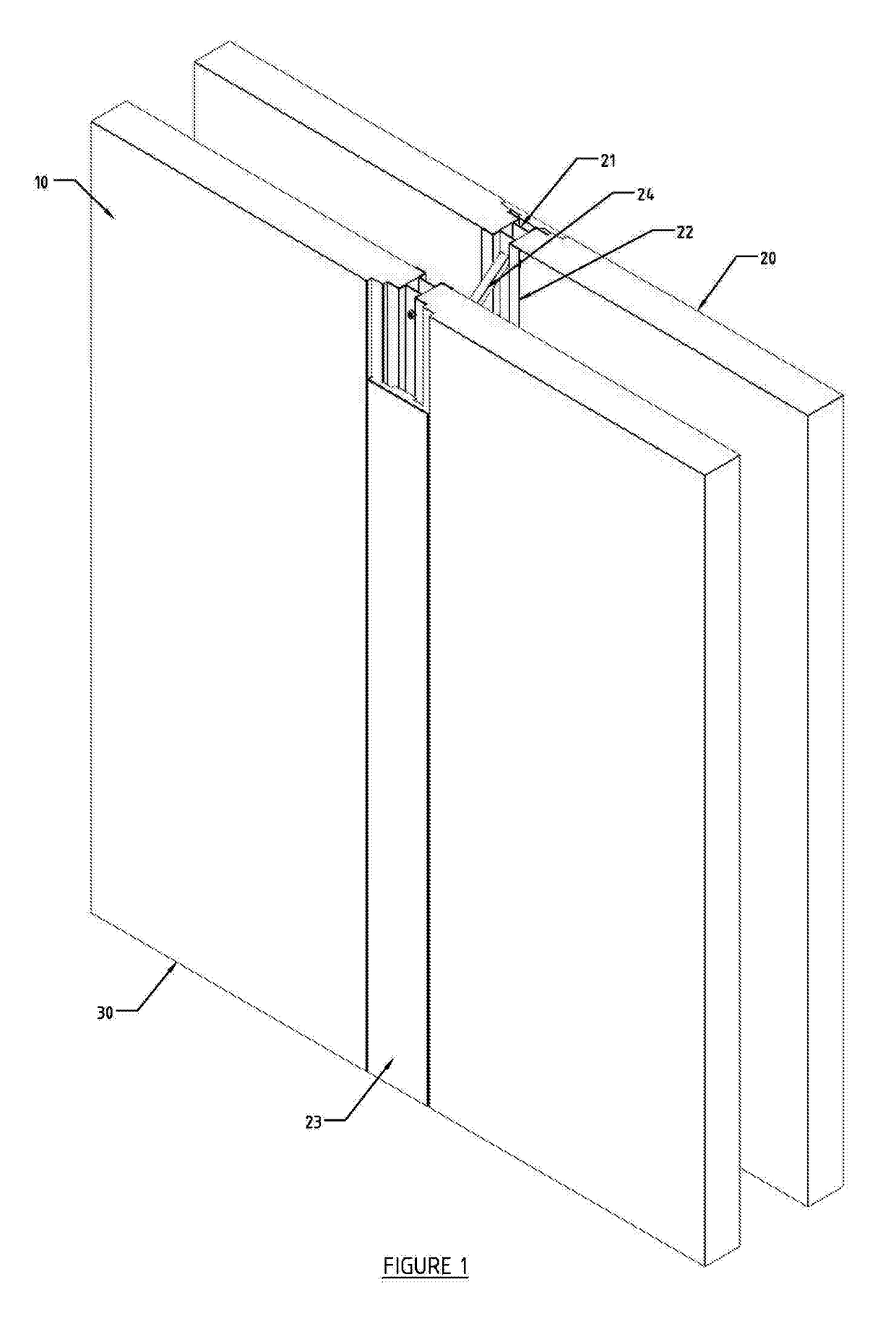

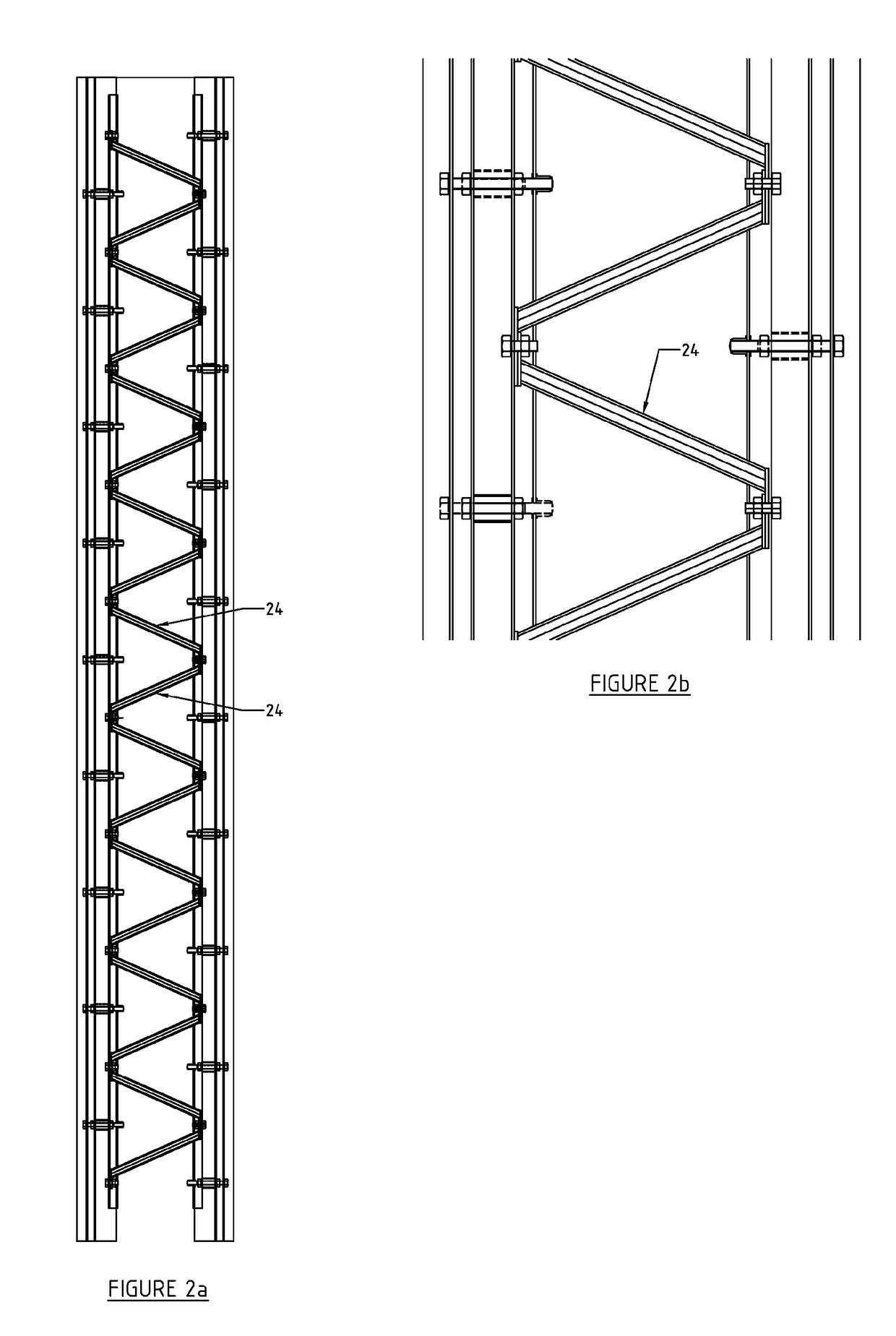

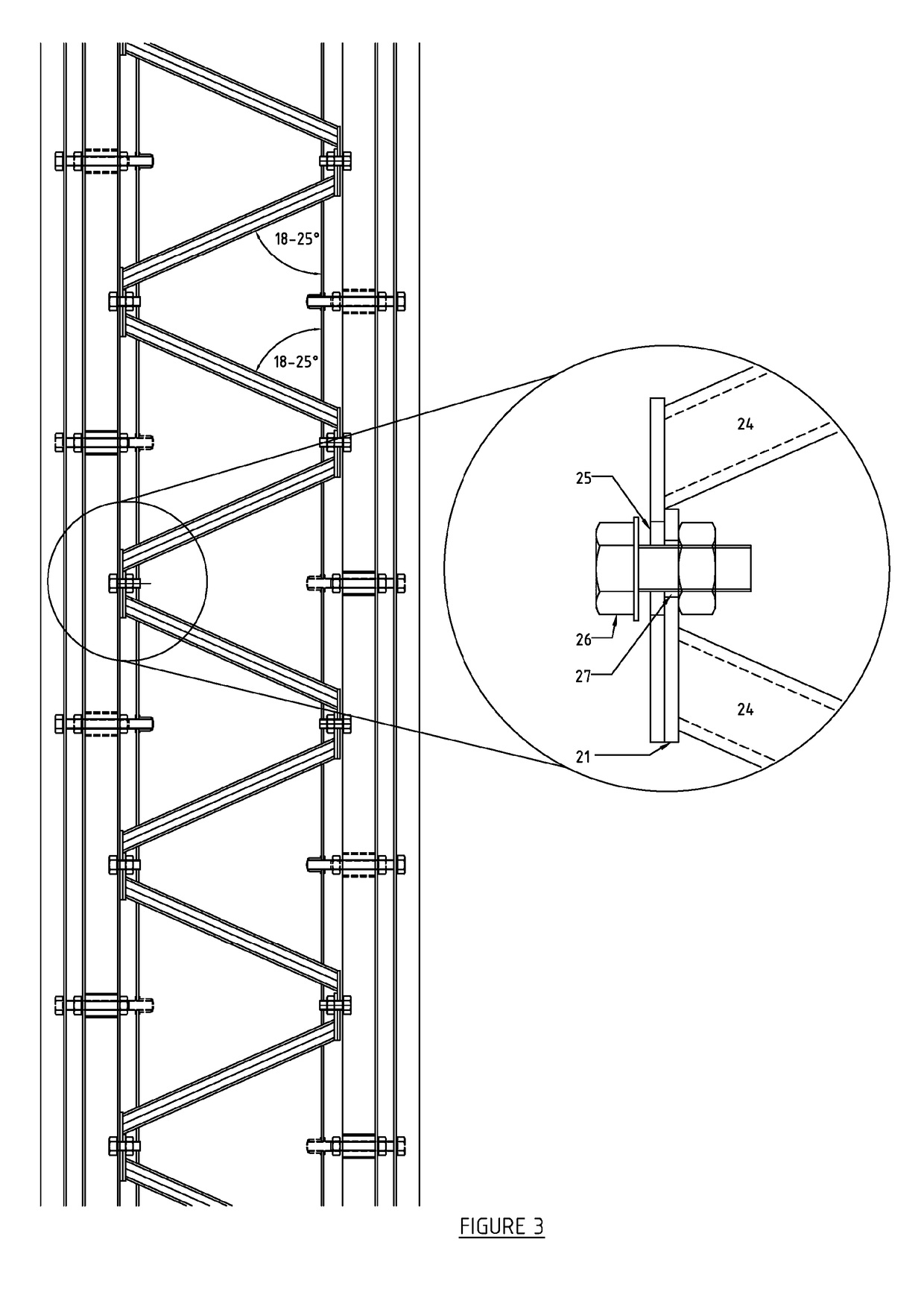

[0033]The invention herein described relates to a series of panels, assembled together in edge-to-edge configuration to form a barrier wall to contain an explosion and / or fire from one side of the wall. Due to the modular nature of the wall, this can be installed relatively quickly when required and also subsequently removed relatively quickly if the need for the wall ends or changes, or to replace a particular panel. The walls contemplated can have a single layer of panels or, in a preferred embodiment, a plurality of layers with two layers being especially preferred. One standard which needs to be met relates to heat transfer which must be sufficiently low that where the temperature on one side of the wall is high, for example of the order of 1500°C., the temperature on the other side of the wall remains below 180°C., which is well below the auto-ignition temperature of many materials such as paper.

[0034]The nature of the assembly means provides for a continuous barrier, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com