Composite textile product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 2

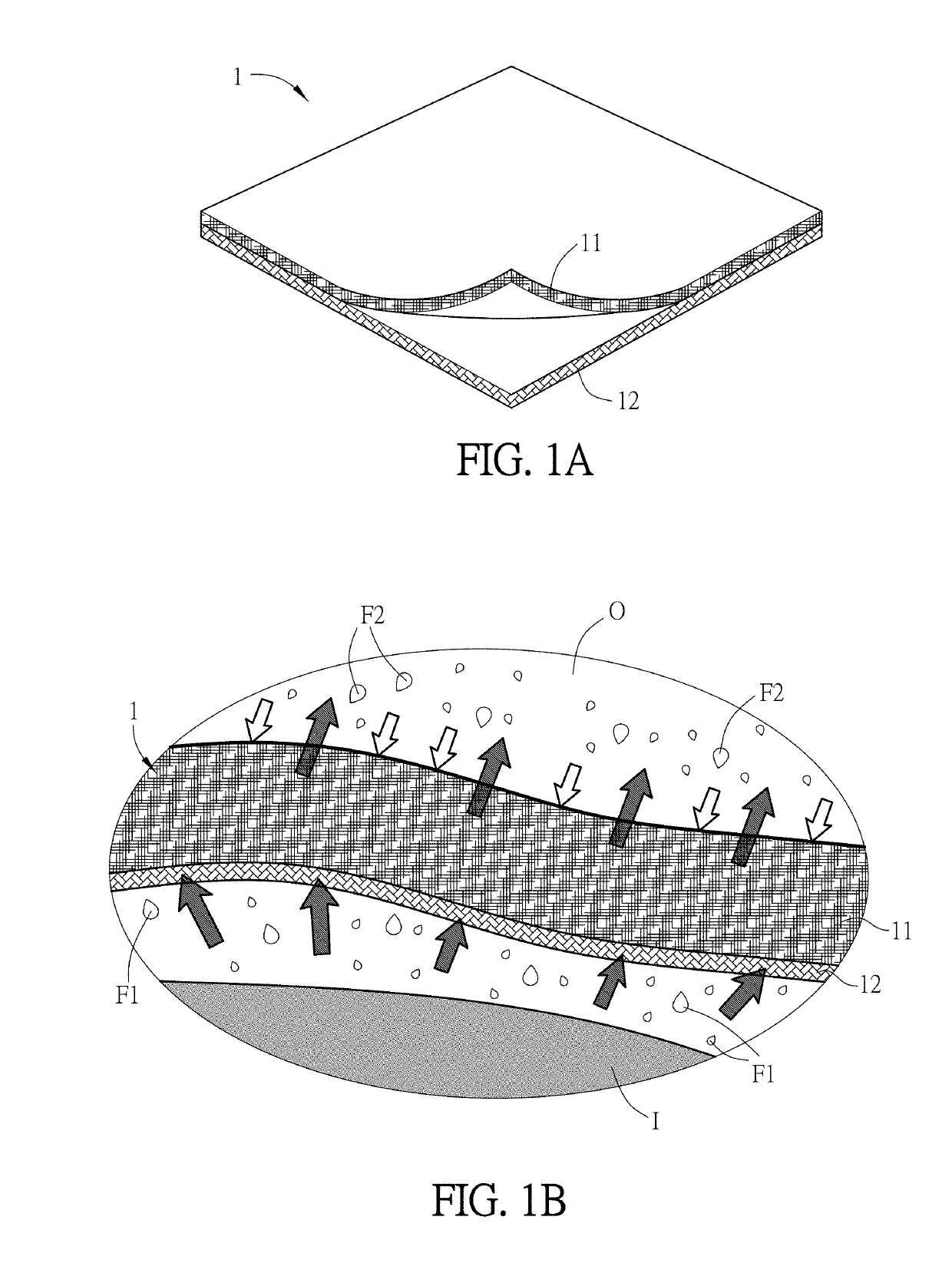

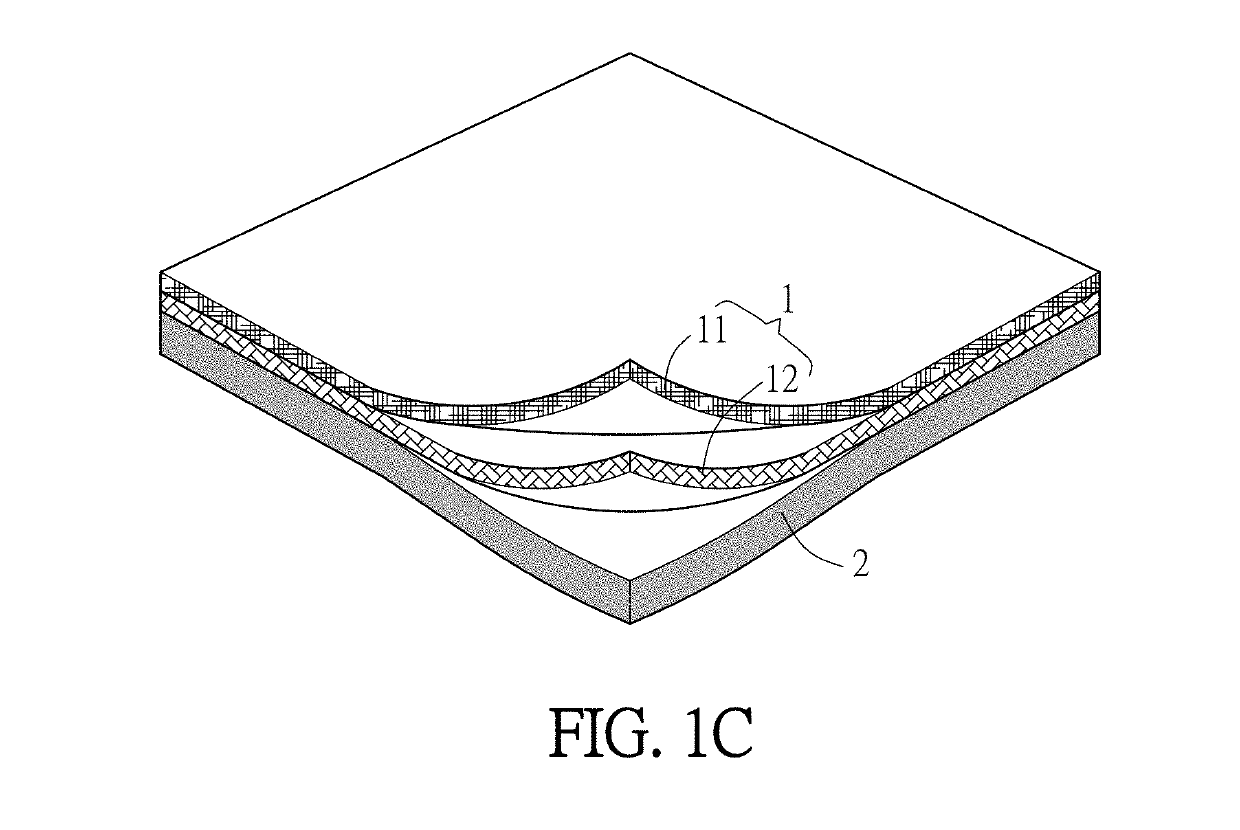

Observation of Composite Textile Product

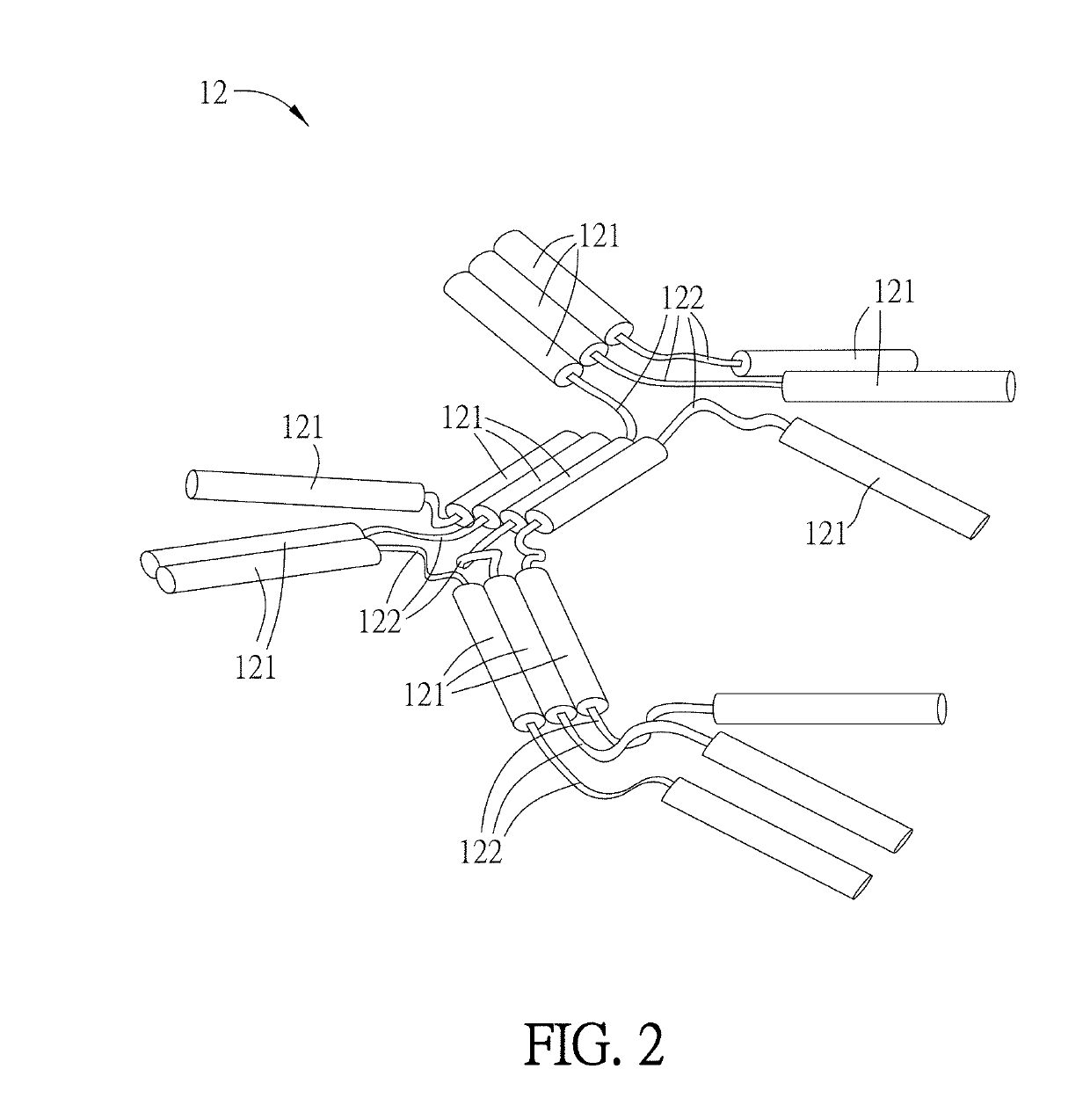

[0045]In this experimental example, the polyamide film of the composite textile product of this embodiment is provided and observed under the electronic microscope so as to realize the pore size of the polyamide film. This experiment is assigned to Plastics Industry Development Center (Taiwan). The electronic microscope observation results are shown in FIGS. 3 and 4. Referring to FIGS. 3 and 4, the pore size of the polyamide film ranges from 11.42 μm to 149.6 μm. Accordingly, the polyamide film can block the passage of liquid water molecules, but allow the passage of gaseous water molecules (water vapor).

[0046]In summary, the composite textile product of this disclosure has a polyamide textile layer and a polyamide film, so that the first fluid containing water molecules (gaseous water) can penetrate through the polyamide film and the polyamide textile layer and then be transmitted to the outer environment, and the second fluid containing wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com