Combi box for the transport and storage of goods

a technology for transporting and storage goods and boxes, applied in the direction of lids, packaging, removable lids/covers, etc., can solve the problems of design not being practical, and achieve the effect of low weight, low cost of series production, and zero cost of extending the product lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

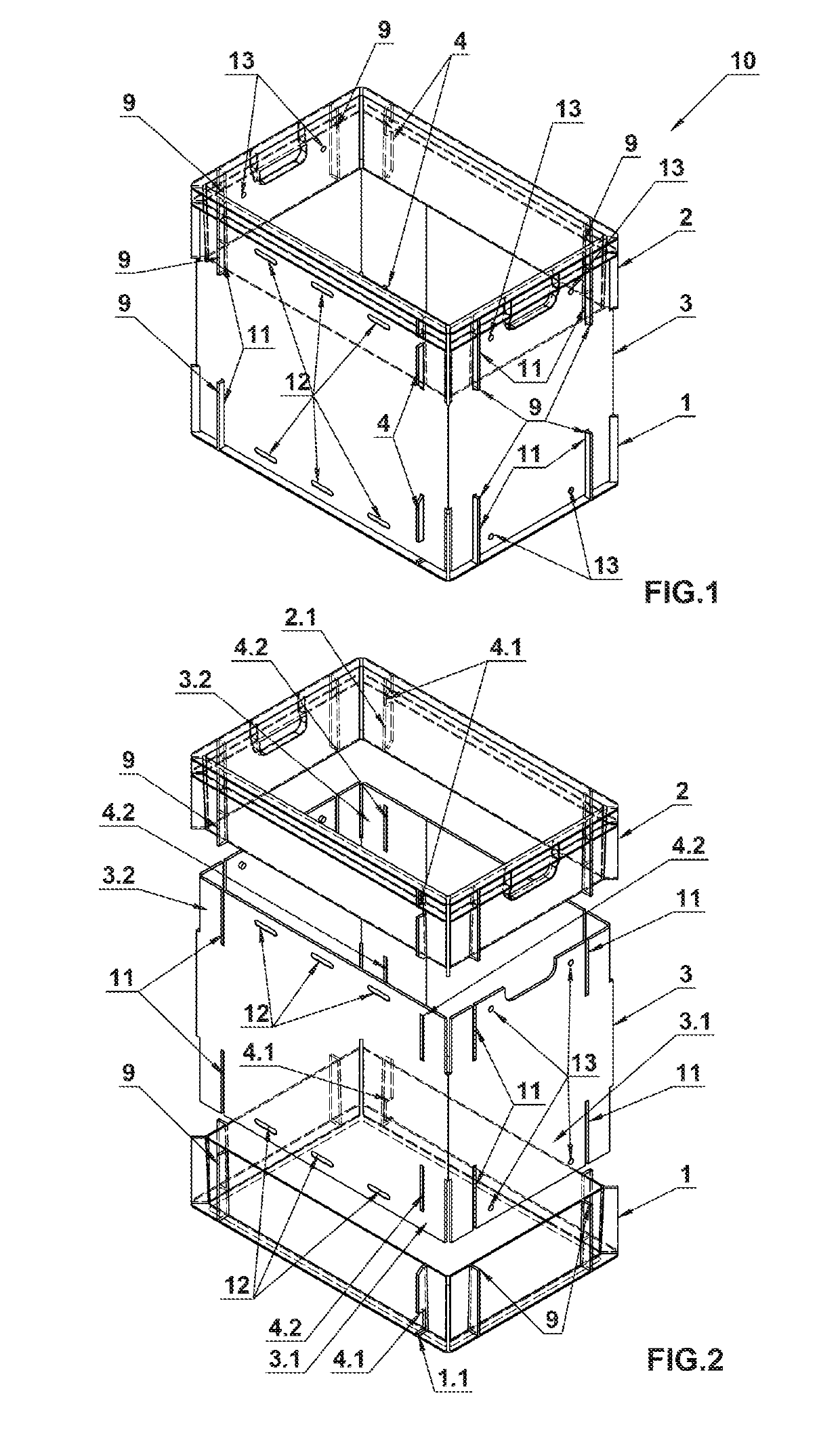

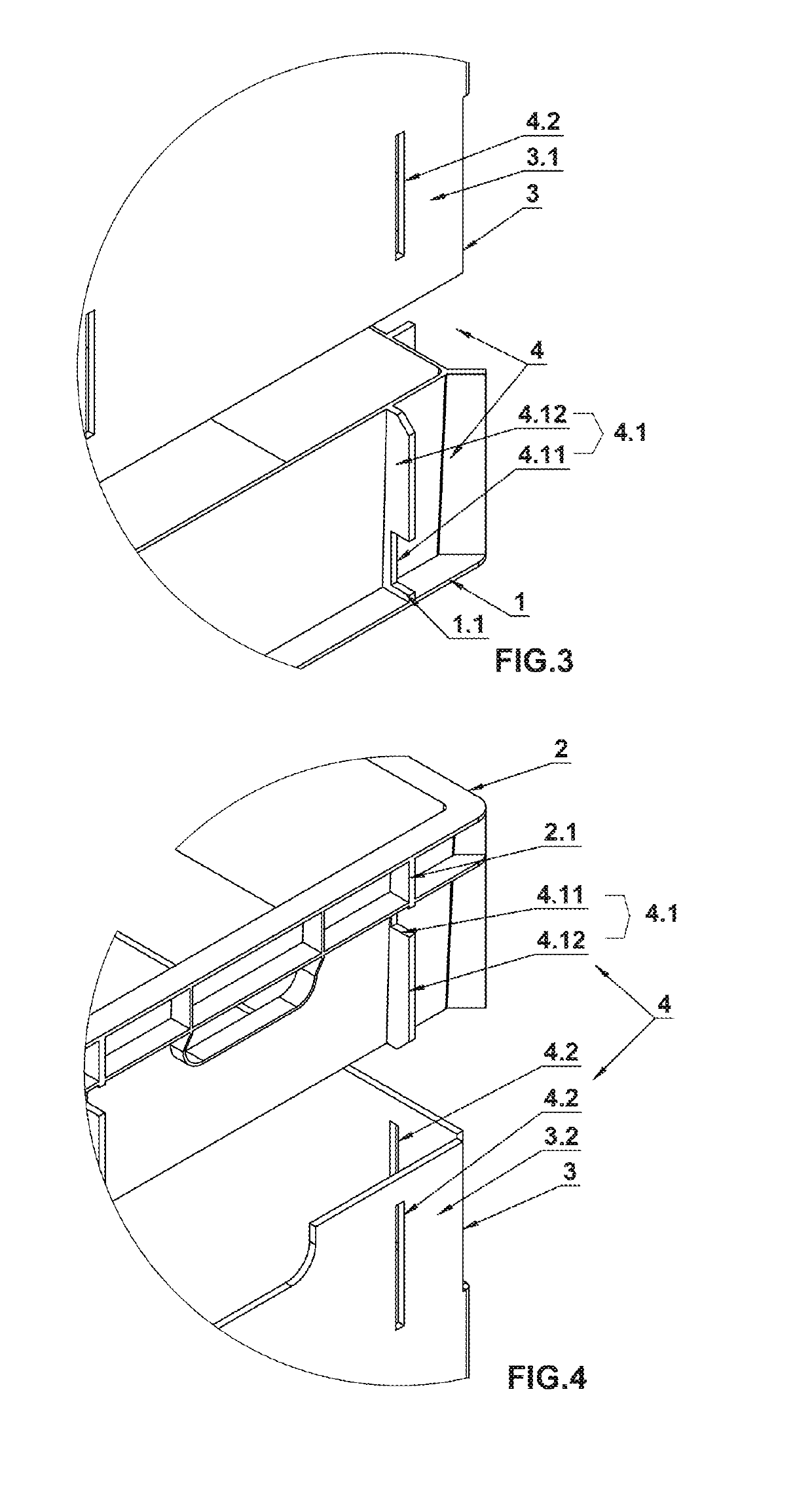

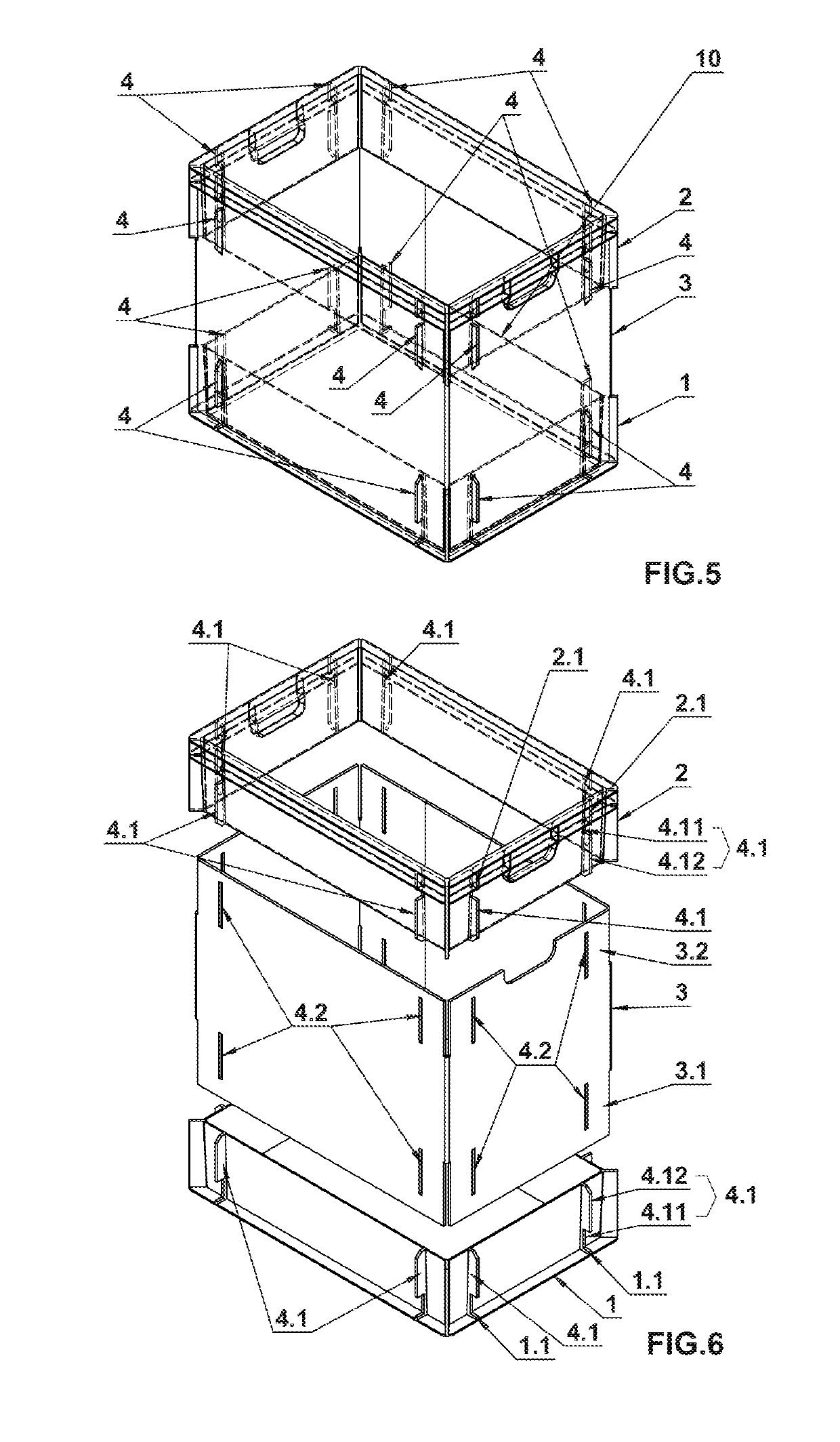

[0025]The combi box 10 for the transport and storage of goods depicted in FIGS. 1 to 18 is made from a conventional or used injection moulded or construction crate. This conventional injection moulded or construction crate is cut approximately in half to create a lower part 1 (hereinafter referred to as a lower frame 1) and an upper part 2 (hereinafter referred to as an upper frame 2). The middle part 3, which is formed by a casing with two open sides, is inserted between the lower frame 1 and the upper frame 2, wherein this middle part 3 may be of different height depending on the type of transported or stored goods. The shape of this middle part 3 corresponds to the shape of the lower frame 1 and the upper frame 2. The middle part 3 is by open sides connected with the lower frame 1 and with the upper frame 2 by means of locking joints 4. Locking joints 4 are formed on the surfaces of the lower perimeter 3.1 and on the surfaces of the upper perimeter 3.2 of the middle part 3 and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com