Liquid storage method and storage device

a liquid storage and storage device technology, applied in tobacco treatment, tobacco, food science, etc., can solve the problems of limited storage time, inconvenient filling tobacco tar into the liquid storage unit/cabinet, and a lot of troublesome spilling of liquids such as tobacco tar, etc., to achieve short delivery time, avoid assembly, and avoid the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0017]This embodiment provides a liquid storage device for storing tobacco tar in an electronic cigarette. As shown in FIG. 1, in this embodiment, the liquid storage device 100 is of an entirely columnar shape, molded by a porous material. The porous material may be selected from ceramic materials such as silicon carbide and aluminum oxide, and porous metallic materials such as stainless steel, copper and nickel. The porosity of the porous material is 5-100 μm. The tobacco tar is stored in pores of the porous material. The tobacco tar enters the pores of the porous material in the capillary principle and siphon principle. In practice, the liquid stock can be adjusted by adjusting the porosities of the porous materials. Generally, the porosity can be 40%, and can be selected within a range of 20%-70% according to demands.

[0018]In this embodiment, it is very easy to place the liquid storage device for storing the tobacco tar. The liquid storage device for storing the tobacco tar is di...

embodiment 2

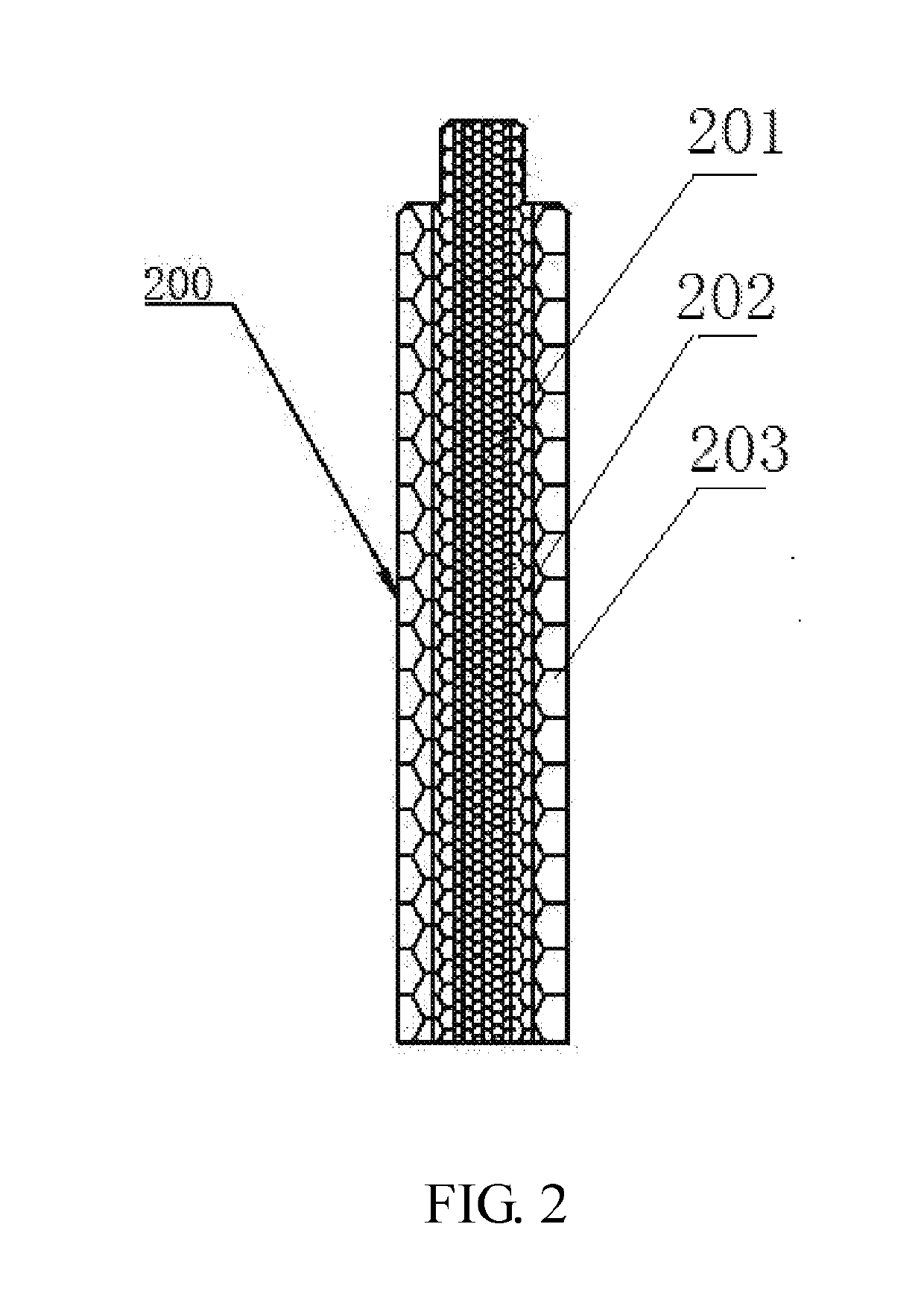

[0021]This embodiment provides a liquid storage device for storing different liquids at the same time. As shown in FIG. 2, in this embodiment, the liquid storage device 200 is comprised of three layers upon demands; different layers have different porosities; the pores of different layers are increasingly increased or reduced in aperture, and are used to store different liquids. As shown in FIG. 2, the liquid storage device in this embodiment is comprised of three layers, respectively an inner liquid storage core 201 that is located in the center and has a aperture of 5-50 μm, a middle liquid storage layer 202 that is located outside the liquid storage core, has an aperture of 30-70 μm and is used to store liquids with a relatively small molecular groups, and an outer liquid storage layer 203 that is located on the outer layer, has an aperture of 50-100 μm and is used to store liquids with a relatively large molecular groups. It is well known that different liquid molecules have dif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap