An industrial textile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]FIG. 1 shows an industrial textile 1 from above. A first surface of the industrial textile 1 is up. The industrial textile 1 has a cross machine direction CMD and a machine direction MD. The cross machine direction CMD corresponds to a weft direction and the machine direction corresponds to a warp direction, i.e. a longitudinal direction of the industrial textile 1. The industrial textile 1 extends from a first edge E1 to a second edge E2.

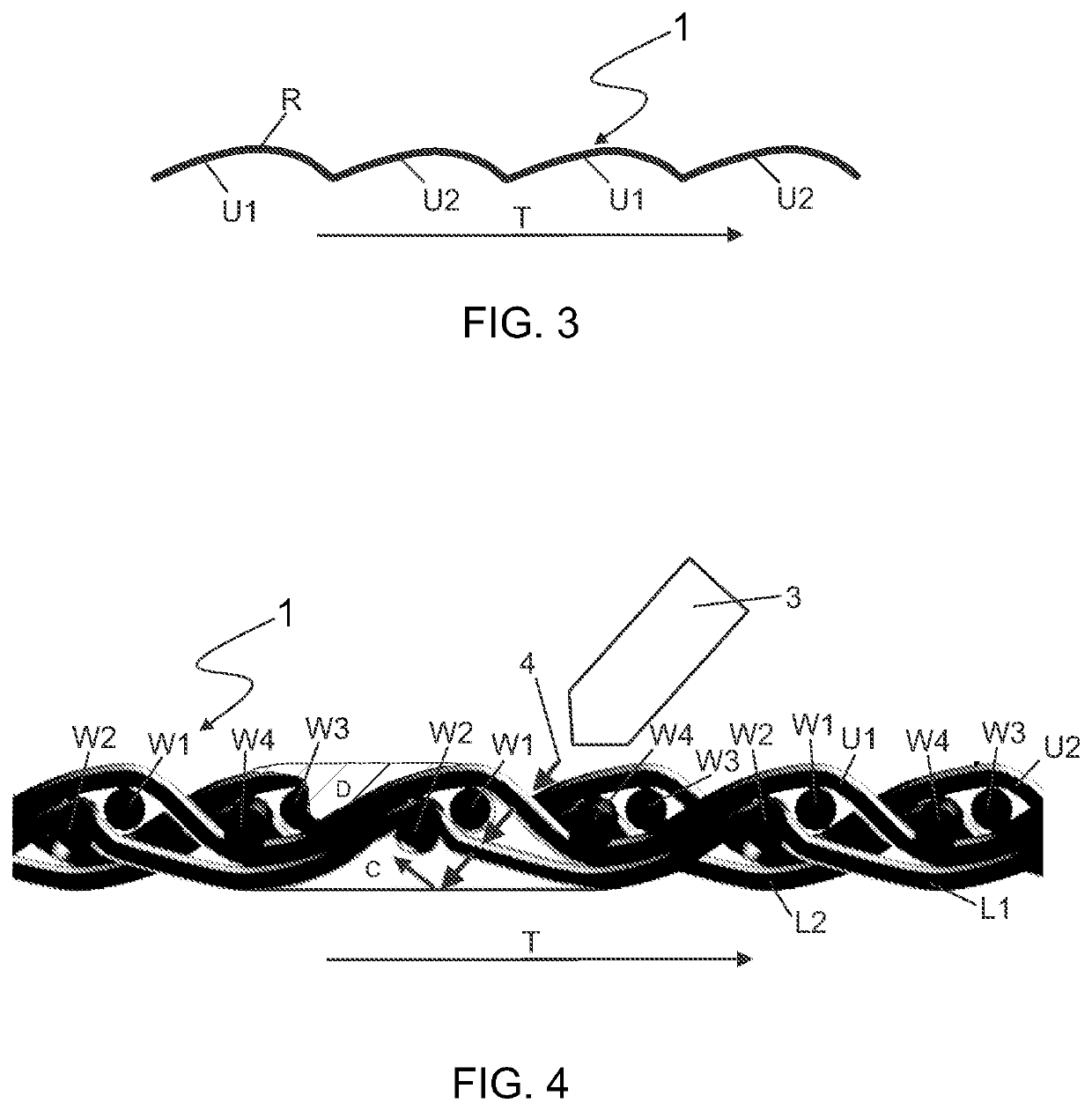

[0025]FIG. 2 shows an industrial textile 1 in a perspective view with the first surface up. The industrial textile 1 comprises yarns U1 and U2 of the first warp, and yarns L1 and L2 of the second warp. The yarns U1 and Ll are essentially one upon the other but the yarns U2 and L2 are offset, i.e. the yarn U2 is shifted laterally in respect of the yarn L2. However, it is possible that also the yarns U1 and L1 are offset. The yarns U1, U2, L1 and L2 are usually monofilament yarns and they may be flat yarns. The warp cover of each warp is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com