Inorganic-organic composite nanoparticle as well as preparation method and application thereof

A technology of composite nanoparticles and silver nanoparticles, applied in the preparation of organic compounds, the preparation of hydroxyl compounds, organic chemistry, etc., can solve the problems of low utilization rate of light energy of catalysts, difficult recycling and reuse of catalysts, etc., and achieve good catalytic reaction effect. , Conducive to the control of performance, the effect of reducing waste of raw materials and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

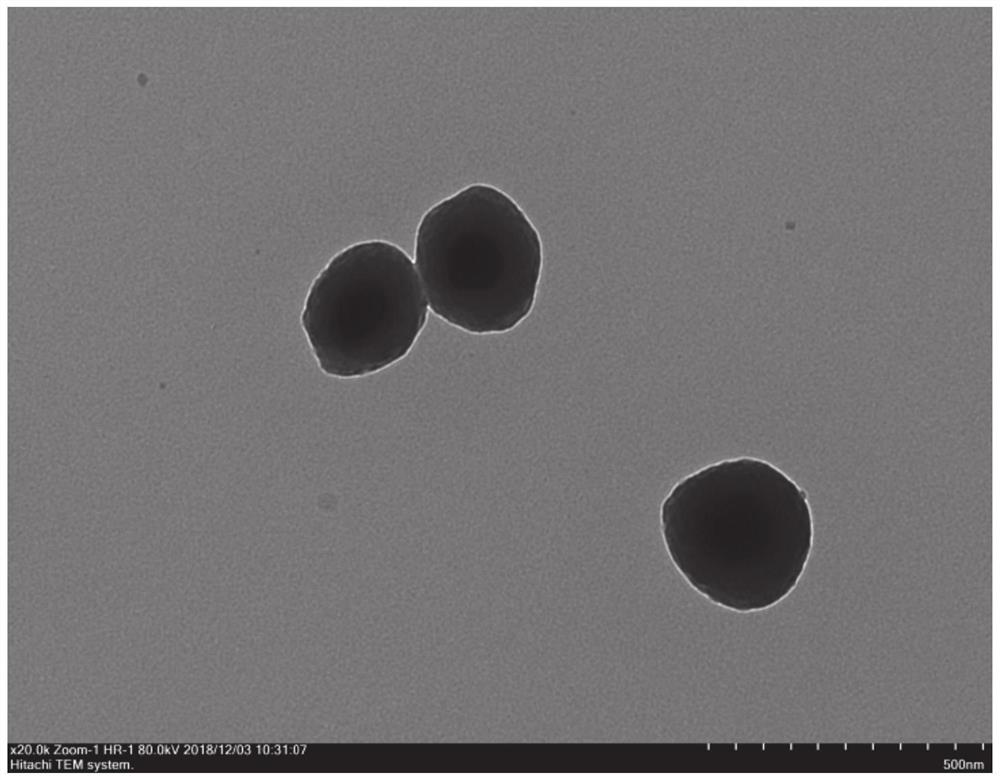

[0028] In one or some embodiments of the present disclosure, a method for preparing inorganic-organic composite nanoparticles is provided, comprising the following steps: ultrasonically dispersing silver nanoparticles in a solvent, adding vinylbenzyl chloride, divinylbenzene, and benzyl peroxide acyl, the system was slowly heated to boiling state, kept boiling to distill off most of the solvent, centrifugally dispersed to obtain inorganic-organic composite nanoparticles, dried and set aside.

[0029] Preferably, the ultrasonic dispersion solvent is acetonitrile;

[0030] Preferably, the mass ratio of silver, vinylbenzyl chloride, divinylbenzene, and benzoyl peroxide is (30-50):(40-60):(40-60):1.

[0031] Preferably, the silver nano-ions are modified with MPS;

[0032] Preferably, the MPS modification method is as follows: add silver nitrate solution, slowly add sodium citrate solution under stirring, and heat in an oil bath for one hour. Afterwards, transfer to the normal te...

Embodiment 1

[0065] This embodiment provides a preparation method of inorganic-organic composite nanoparticles, comprising the following steps:

[0066] Take a 250ml one-necked flask, add 200ml of silver nitrate solution with a concentration of 1.5mmol·L-1, slowly add 8mL of 1% sodium citrate solution under stirring, and heat in an oil bath at 100°C for one hour. Afterwards, transfer to a normal temperature water bath and continue to stir for 6 hours to obtain a silver nanoparticle sol mixed solution.

[0067] Another 500ml single-necked round-bottomed flask was added, 100ml of the above-mentioned silver nanoparticle sol mixed solution and 300ml of absolute ethanol were added, stirred at room temperature for 5 minutes, then 10ml of ammonia was added, and 200mg of 3-(methacryloyloxy)propane was added under continuous stirring. Trimethoxysilane (MPS), stirred at room temperature for 48 hours, centrifuged to remove the supernatant and washed three times with ethanol to obtain MPS-modified Ag ...

Embodiment 2

[0070] This embodiment provides a method for photocatalytic reduction of carbon dioxide to generate methanol, comprising the following steps:

[0071] Take 40 mg of the core-shell inorganic-organic composite nanoparticles in Example 1 and ultrasonically disperse them in 10 ml of tetrahydrofuran, add 200 ul of bis(trimethylsilyl) potassium amide under stirring, and react with stirring at room temperature for 4 hours. Carbon dioxide was bubbled in until saturated, after which the reaction was continued to stir for two hours. Centrifuge to remove supernatant. Continue to disperse in 1ml of 1,4-dioxane, add 50ul of deionized water, 10mg of N,N,N',N'-tetramethylbenzidine (TMB), and irradiate with a 340nm mercury lamp for 8 hours , centrifuge to take the supernatant, and rectify to distill out methanol, the product of catalytic reduction of nitrogen dioxide.

[0072] Determination of methanol production in 0.5h was 20mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com