Structure for reducing the drag of a ship and its application

a technology for reducing the drag of ships and ships, applied in the direction of watercraft hull design, hull construction, etc., can solve the problems of increasing fuel consumption, slowing down the speed of ships, and ship drag, so as to and reduce the drag of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to lay out the above and other purposes, features and advantages of the present invention more explicitly, the embodiments are described herein with reference to the accompanying drawings.

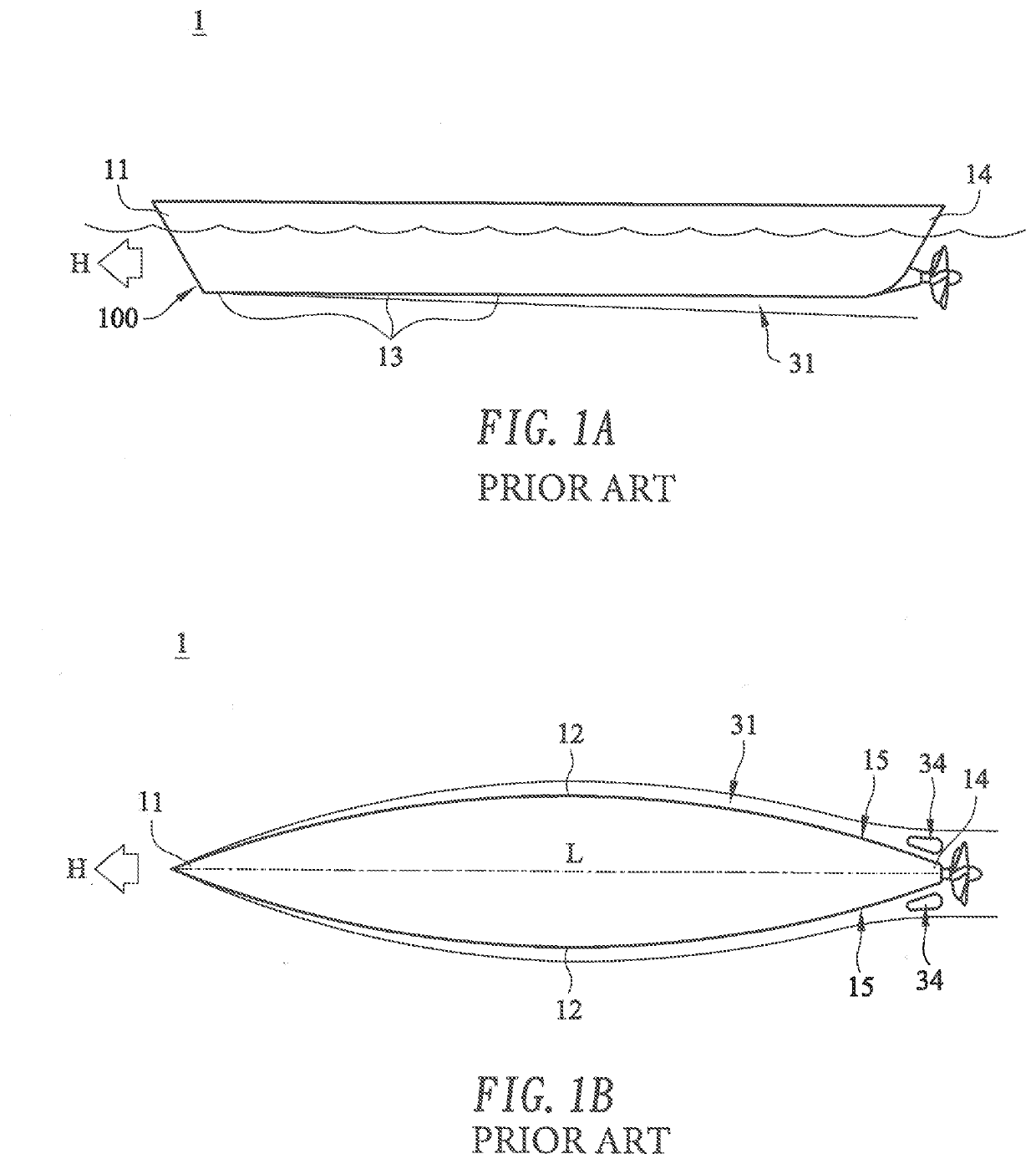

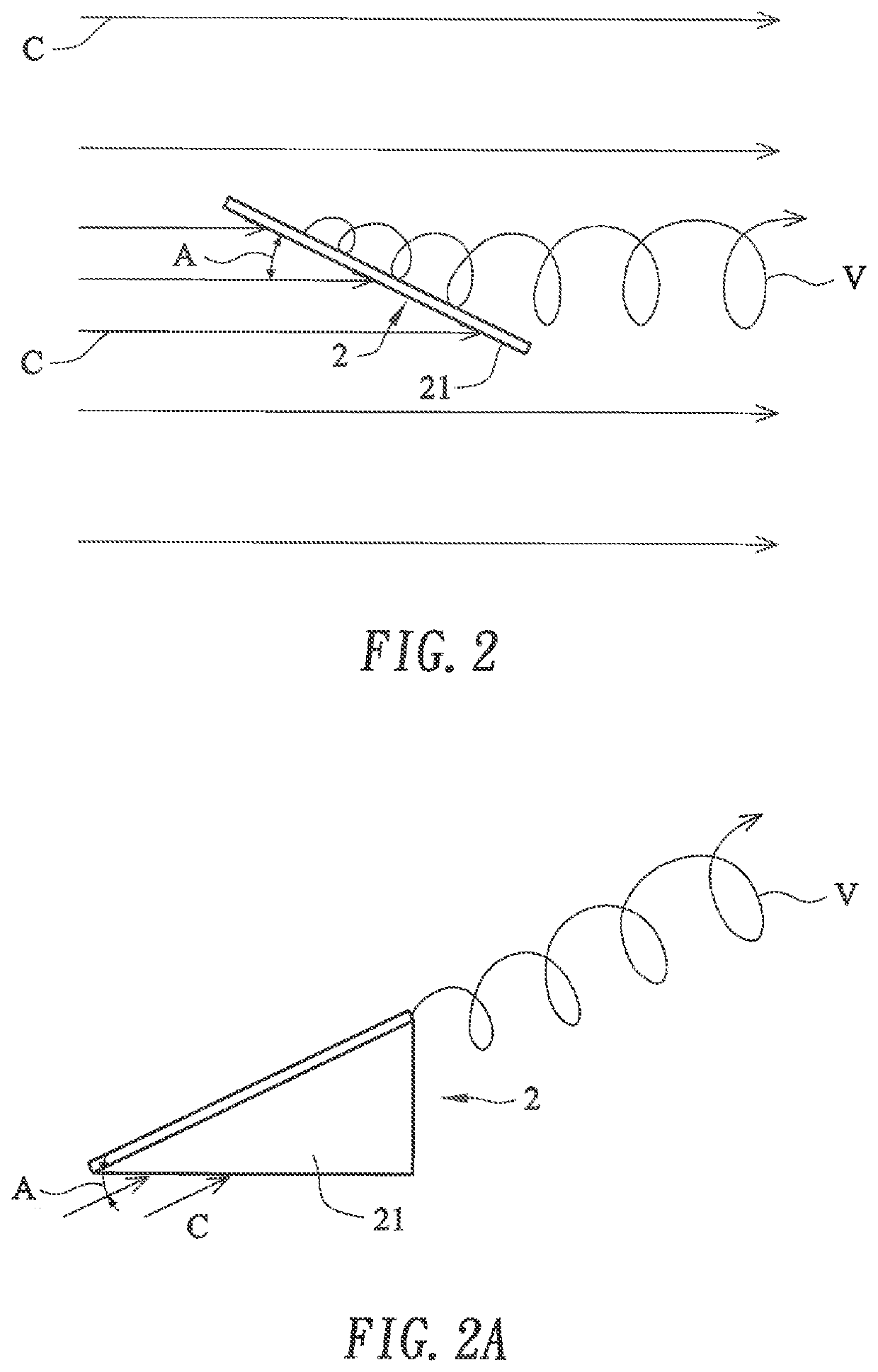

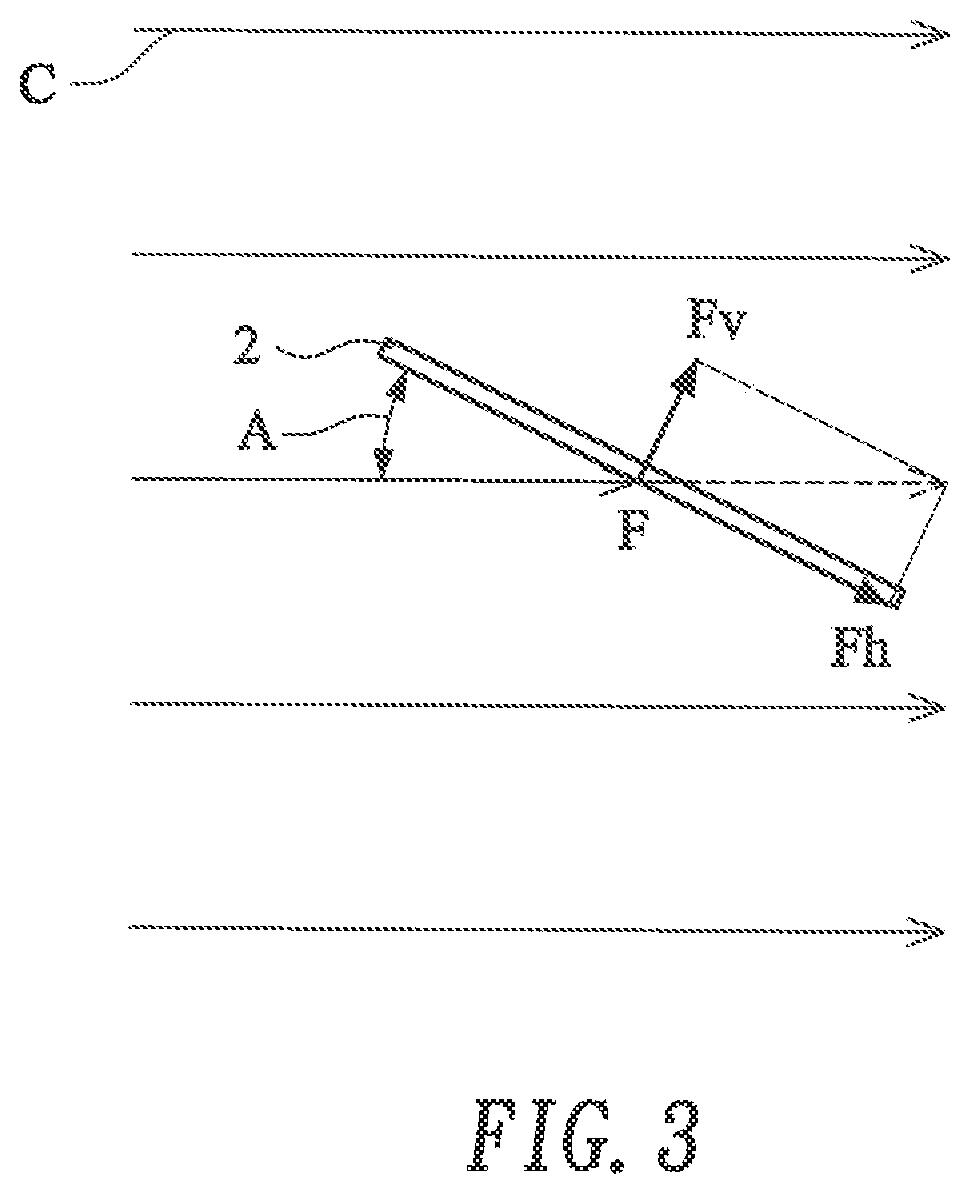

[0036]Referring to FIGS. 2 and 3, the variation and the effects of the current when it encounters the turbulence generating structure of the present invention is described as follows. As shown in FIG. 2 and FIG. 7, a turbulence generating structure 2 installed on the hull 100 of a ship 1 comprises an impact surface 21 facing the incoming flow of water for colliding with and generating turbulence when the flow collides with the impact surface 21. The turbulence generating structure 2 also comprises a front surface 22 with a shape of a slope or curved surface as shown in FIG. 12. When the ship 1 is in the H sailing traveling forward, the front surface 22 of the turbulence generating structure 2 face water current. Since the shape of the front surface 22 is a slope or curved surface, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com