Prefabricated fencing system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

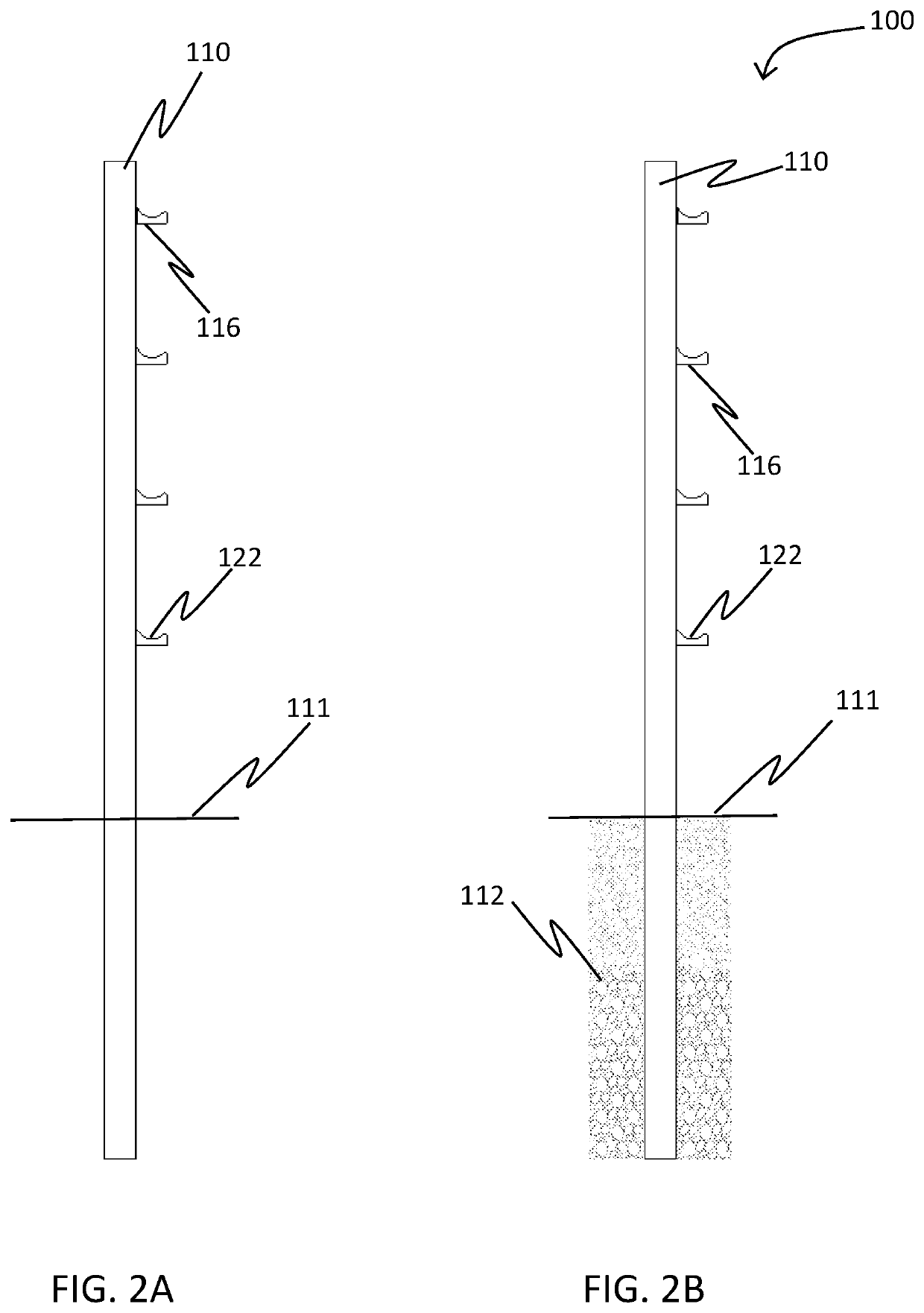

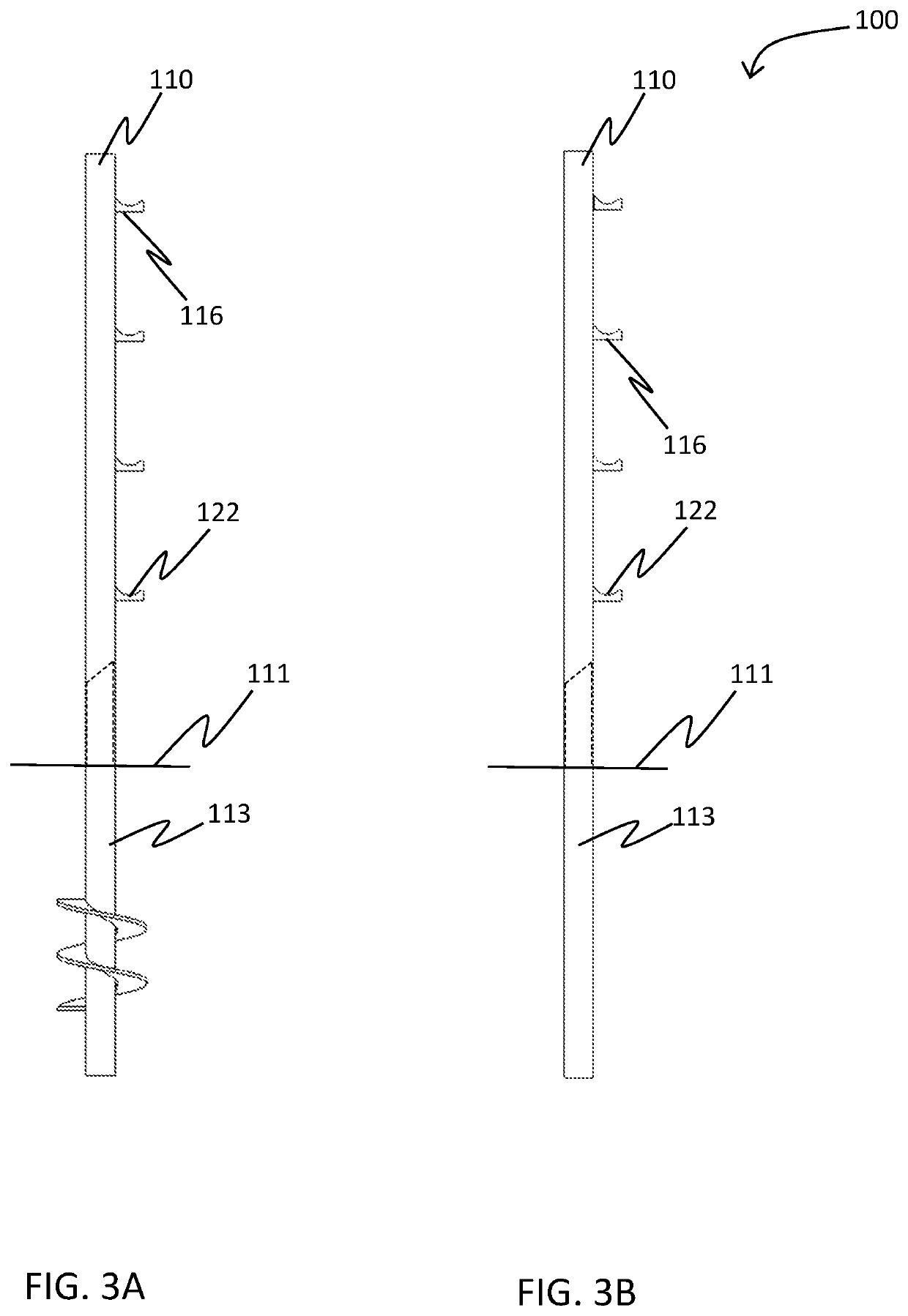

[0018]As discussed above, embodiments of the present disclosure relate to fences and more particularly to a prefabricated fencing system as used to improve fencing for a continuous fencing system.

[0019]Generally speaking, a prefabricated fence post may be constructed from sections of steel to be used for continuous fencing. The fence post preferably includes hooked gussets welded on the side of the post that allows the installer to use pipe as the rail. Preferably, each gusset has a curved notch about the same size as the diameter of the pipe being used for the rails. The notch is helpful in holding the pipe in place, as the fence is being erected by keeping the pipe sections in place while the sections are being coupled together. Once the posts have the sections of pipe perched on the gussets and coupled, the rails can then be welded to the gussets creating a high quality, long lasting fence achieved with minimal time to install using lower cost tubing.

[0020]Referring now, more spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com