Silicone-modified epoxy resin composition and semiconductor device

a technology of epoxy resin and semiconductor devices, which is applied in the direction of semiconductor devices, basic electric elements, electrical apparatus, etc., can solve the problems of reducing heat resistance, affecting reliability, and difficult to secure space distances and creepage distances, so as to reduce modulus, suppress cracking or separation risk, and enhance tracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

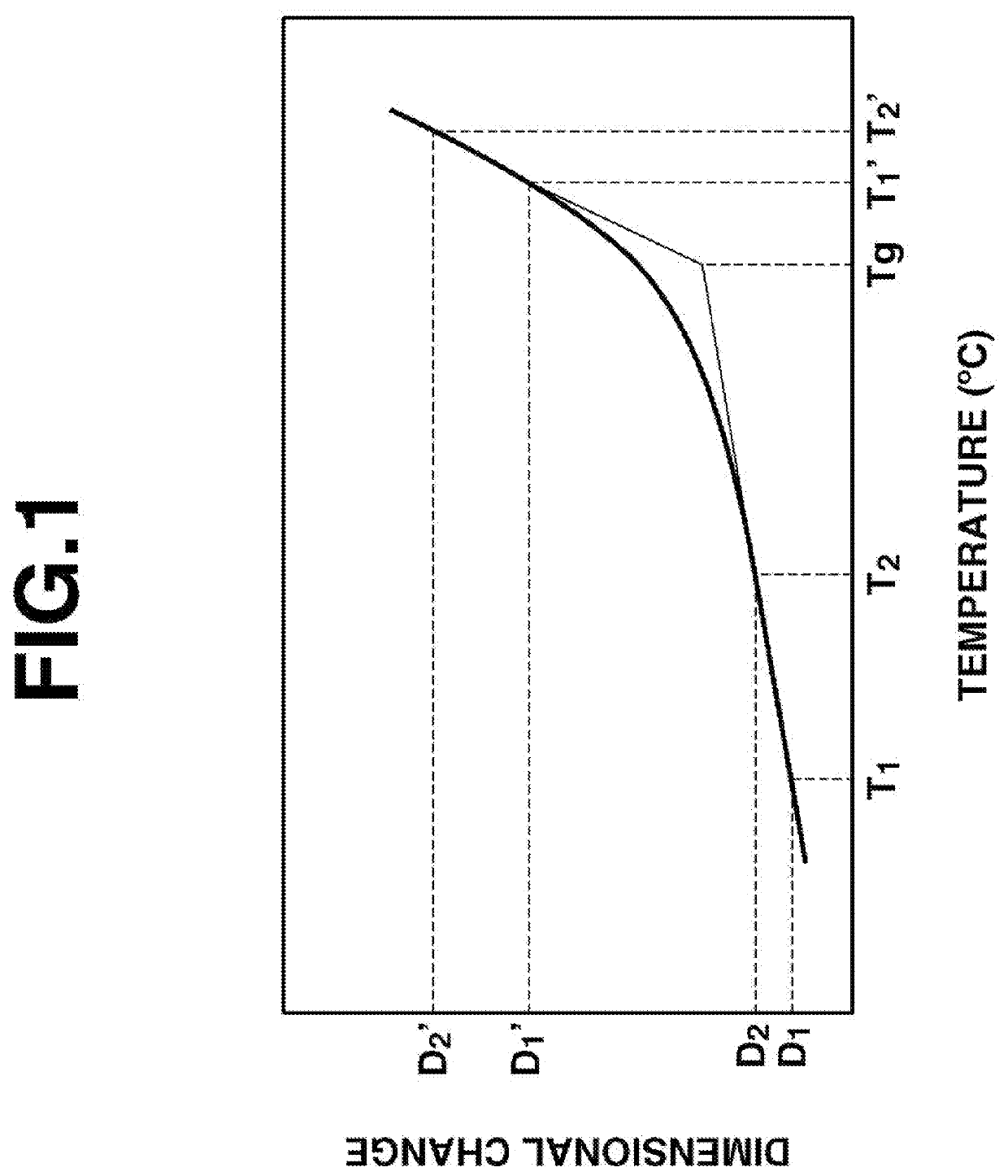

Image

Examples

first embodiment

[0047]The first embodiment of the invention is a resin composition comprising:

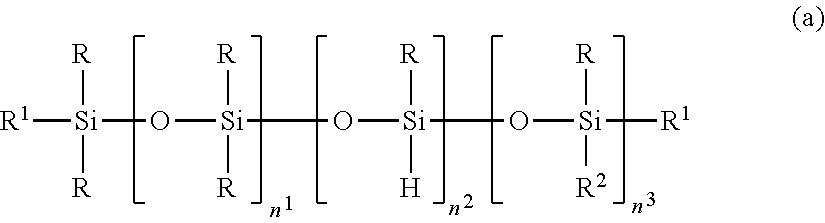

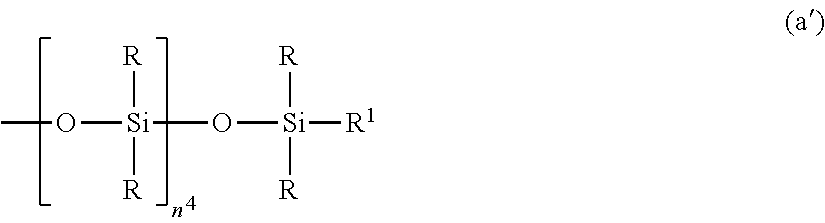

[0048](A) a silicone-modified epoxy resin obtained from hydrosilylation reaction of an alkenyl-containing epoxy compound with an organopolysiloxane having the average compositional formula (1),

[0049](B) a silicone-modified phenolic resin obtained from hydrosilylation reaction of an alkenyl-containing phenol compound with an organopolysiloxane having the average compositional formula (1),

[0050](C) a black pigment, and

[0051](D) an inorganic filler exclusive of the black pigment (C).

(A) Silicone-Modified Epoxy Resin

[0052]Component (A) is a copolymer obtained from hydrosilylation reaction of an alkenyl-containing epoxy compound with a hydrogenorganopolysiloxane having the average compositional formula (1). The inclusion of the copolymer ensures that the resin composition of the first embodiment has high heat resistance, hygroscopicity, tracking resistance, and flow.

[0053]The alkenyl-containing epoxy compound u...

second embodiment

[0081]The second embodiment of the invention is a resin composition comprising:

[0082](P) a cyanate ester compound having at least two cyanato groups per molecule,

[0083](A) a silicone-modified epoxy resin obtained from hydrosilylation reaction of an alkenyl-containing epoxy compound with an organopolysiloxane having the average compositional formula (1), and

[0084](F) a phenol compound having at least two phenolic hydroxyl groups per molecule and / or a silicone-modified phenolic resin obtained from hydrosilylation reaction of an alkenyl-containing phenol compound with an organopolysiloxane having the average compositional formula (1).

(P) Cyanate Ester Compound

[0085]Component (P) is a cyanate ester compound having at least two cyanato groups per molecule. Any well-known cyanate may be used as long as it has at least two cyanato groups per molecule. For example, cyanate ester compounds having the general formula (2) are useful.

Herein R1 and R2 are each independently hydrogen or C1-C4 alk...

example

[0112]Examples of the invention are given below by way of illustration and not by way of limitation.

Resin Composition of First Embodiment

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com