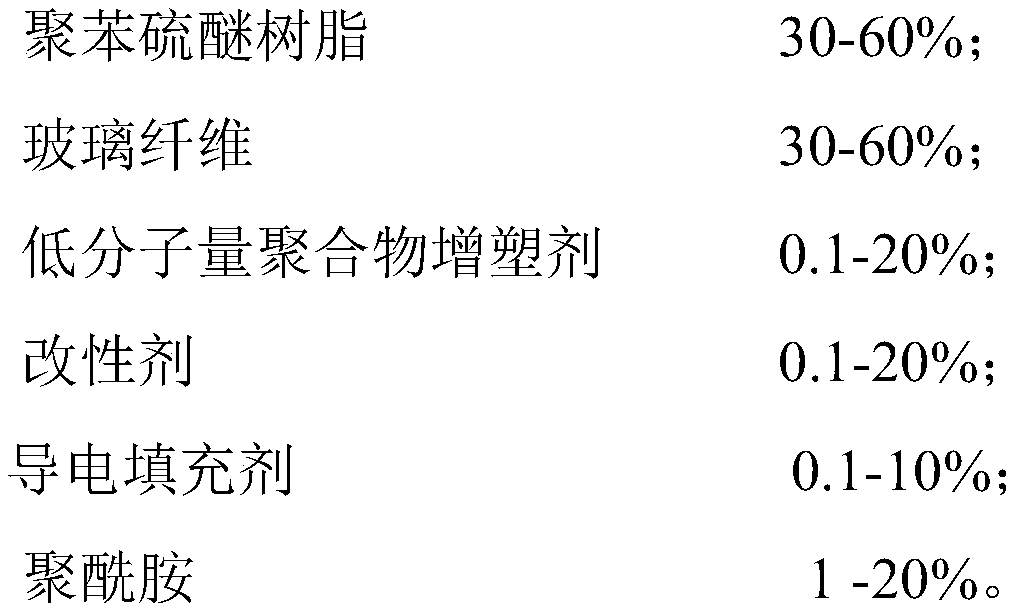

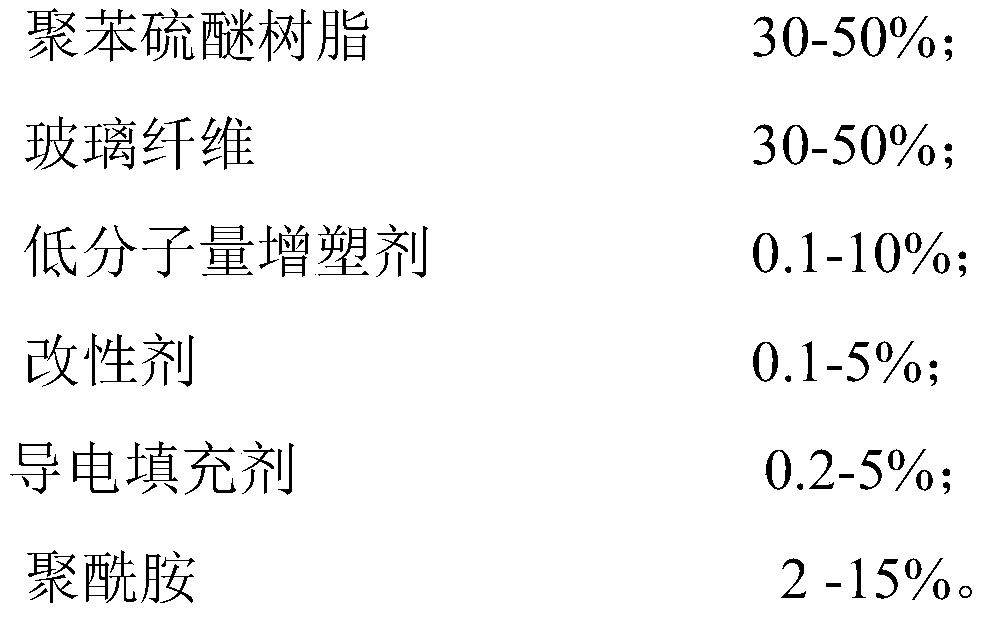

A kind of polyphenylene sulfide composite material and its preparation method and application

A composite material and polyphenylene sulfide technology, which is applied in the field of high-comparison tracking index polyphenylene sulfide reinforced composite materials and their preparation fields, can solve the problems of tracking, poor fluidity of the polyphenylene sulfide composite, etc. The effect of improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In addition, the present invention also provides a kind of preparation method of above-mentioned polyphenylene sulfide composite material, and described method comprises the following steps:

[0061] (1) Take polyphenylene sulfide resin, low molecular weight plasticizer, modifier, and conductive filler by weight and mix evenly to obtain premix 1;

[0062] (2) Add premix 1 to the twin-screw extruder, then add glass fiber, and turn on the vacuum exhaust pump after the extrusion is stable, and the molten material strip is drawn from the die of the extruder into the water tank, cooled and solidified , pelletizing to obtain the granular composite material 1;

[0063] (3) drying the granular composite material 1 obtained in step (2);

[0064] (4) Weigh the dried granular composite material 1 and polyamide in proportion by weight and mix them uniformly to obtain a premix 2;

[0065] (5) Add the premix 2 obtained in step (4) to the twin-screw extruder, turn on the vacuum exha...

Embodiment 1

[0074] (1) Take polyphenylene sulfide resin, low molecular weight plasticizer, modifier, conductive filler and mix uniformly according to the weight ratio in Table 1 to obtain premix 1;

[0075] (2) Add the premix 1 into the preheated twin-screw extruder from the main feeding port, and add the long glass fiber from the side feeding port; after the extrusion is stable, turn on the vacuum exhaust pump; melt the material The strip is pulled from the die of the extruder into the water tank to cool and solidify, and then enters the pelletizing device to be cut into granular composite materials 1;

[0076] (3) Dry the granular composite material 1 in a blast drying oven at a temperature of 90-110° C. for 1-2 hours;

[0077] (4) Take the dried granular composite material 1 and polyamide according to the weight ratio in Table 1 and mix them uniformly to obtain the premix 2;

[0078](5) Add the premix 2 from the main feeding port into the twin-screw extruder that has been preheated in...

Embodiment 2

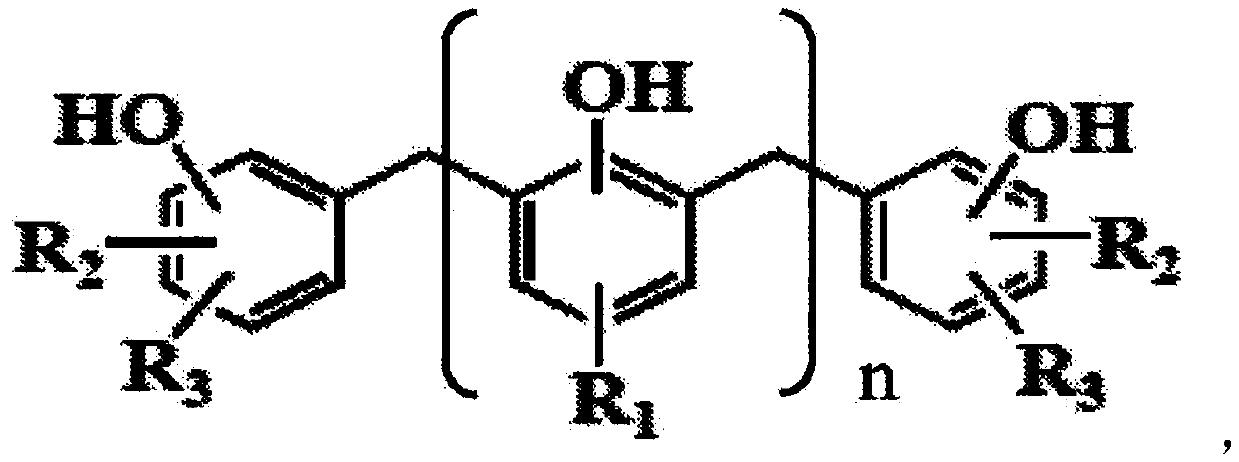

[0097] A polyphenylene sulfide reinforced composite material is prepared in the same manner as in Example 1, and is prepared according to the weight ratio including the raw materials in the following table 5:

[0098] Table five

[0099] components weight(%) polyphenylene sulfide resin 45 Low molecular weight plasticizer (low molecular weight polystyrene) 7 Modifier (compound of formula I) 2 glass fiber 30 Conductive filler (conductive graphite) 1 Polyamide resin (polytoluene adipamide) 15

[0100] The low molecular weight polystyrene in Table 5 has a weight average molecular weight of 60,000-70,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com