High flowability, low viscosity and high impact resistance ABS resin and preparation method

A technology of ABS resin and high impact resistance, which is applied in the field of polymer material synthesis and preparation, can solve the problems of large environmental pollution and a large amount of waste water, and achieve the effects of high melt index, poor fluidity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

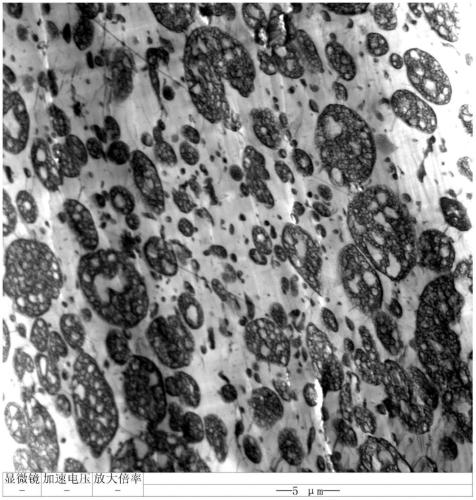

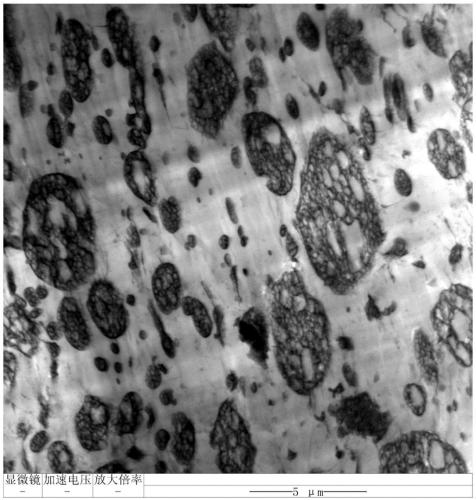

Image

Examples

Embodiment 1

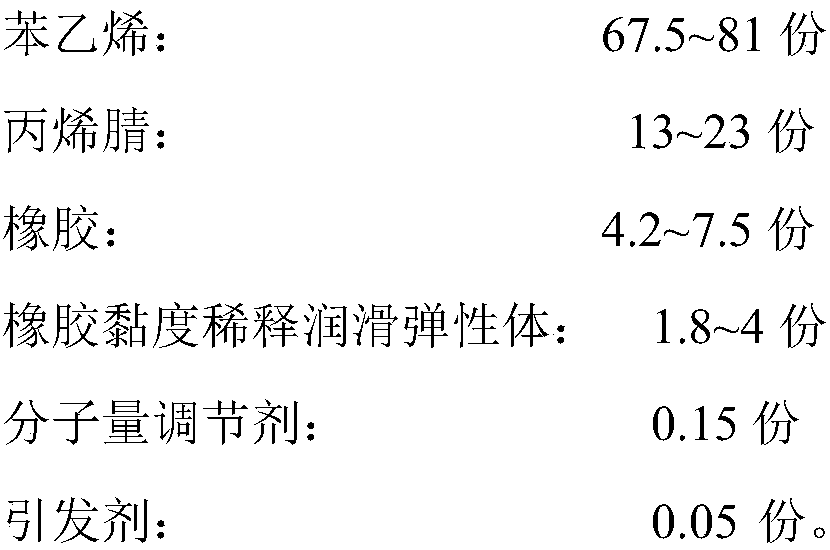

[0048] The high-flow, low-viscosity, high-impact body ABS resin in this embodiment includes 70% monomer and rubber mixture and 30% diluent; the body and rubber mixture include the following components in parts by weight: 77 parts of styrene 13 parts of acrylonitrile; 6 parts of polybutadiene rubber; 4 parts of SBS rubber viscosity dilution lubricating elastomer; 0.05 part of initiator; 0.15 part of molecular weight regulator. The ratio of xylene to ethylbenzene in said particular diluent is 70 / 30.

[0049] The preparation method of the high-flowability, low-viscosity and high-impact bulk ABS resin comprises the following steps:

[0050] Preparation of pre-polymerization raw material solution: styrene, acrylonitrile, and diluent are prepared into a mixed solution, polybutadiene rubber and rubber viscosity-diluted lubricating elastomer are pulverized and added to the mixed solution, and stirred until the rubber is completely dissolved to obtain a pre-polymerized Raw material li...

Embodiment 2

[0054] The high-flow, low-viscosity, high-impact body ABS resin in this embodiment includes 70% monomer and rubber mixture and 30% diluent; the body and rubber mixture include the following components in parts by weight: 77 parts of styrene 13 parts of acrylonitrile; 7 parts of polybutadiene rubber; 3 parts of SBS rubber viscosity dilution lubricating elastomer; 0.05 part of initiator; 0.15 part of molecular weight regulator. The ratio of xylene to ethylbenzene in the particular solvent is 70 / 30.

[0055] The preparation method of the high-flowability, low-viscosity and high-impact bulk ABS resin comprises the following steps:

[0056] Preparation of pre-polymerization raw material solution: styrene, acrylonitrile, and diluent are prepared into a mixed solution, polybutadiene rubber and rubber viscosity-diluted lubricating elastomer are pulverized and added to the mixed solution, and stirred until the rubber is completely dissolved to obtain a pre-polymerized Raw material liq...

Embodiment 3

[0060] The high-flow, low-viscosity, high-impact body ABS resin in this embodiment includes 70% monomer and rubber mixture and 30% diluent; the body and rubber mixture include the following components in parts by weight: 81 parts of styrene 13 parts of acrylonitrile; 4.2 parts of polybutadiene rubber; 1.8 parts of SBS rubber viscosity dilution lubricating elastomer; 0.05 part of initiator; / 30.

[0061] The preparation method of the high-flowability, low-viscosity and high-impact bulk ABS resin comprises the following steps:

[0062] Preparation of pre-polymerization raw material solution: styrene, acrylonitrile, and diluent are prepared into a mixed solution, polybutadiene rubber and rubber viscosity-diluted lubricating elastomer are pulverized and added to the mixed solution, and stirred until the rubber is completely dissolved to obtain a pre-polymerized Raw material liquid;

[0063] Polymerization reaction step: adding the pre-polymerization raw material liquid into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com