Motor and spoke-type rotor structure thereof

a rotor and spoke-type technology, which is applied in the direction of dynamo-electric machines, magnetic circuit rotating parts, magnetic circuit shape/form/construction, etc., can solve the problems of loss of magnetic lines of force and affect the efficiency of the motor, and achieve the effect of reducing the number of rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

ss="d_n">[0025]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

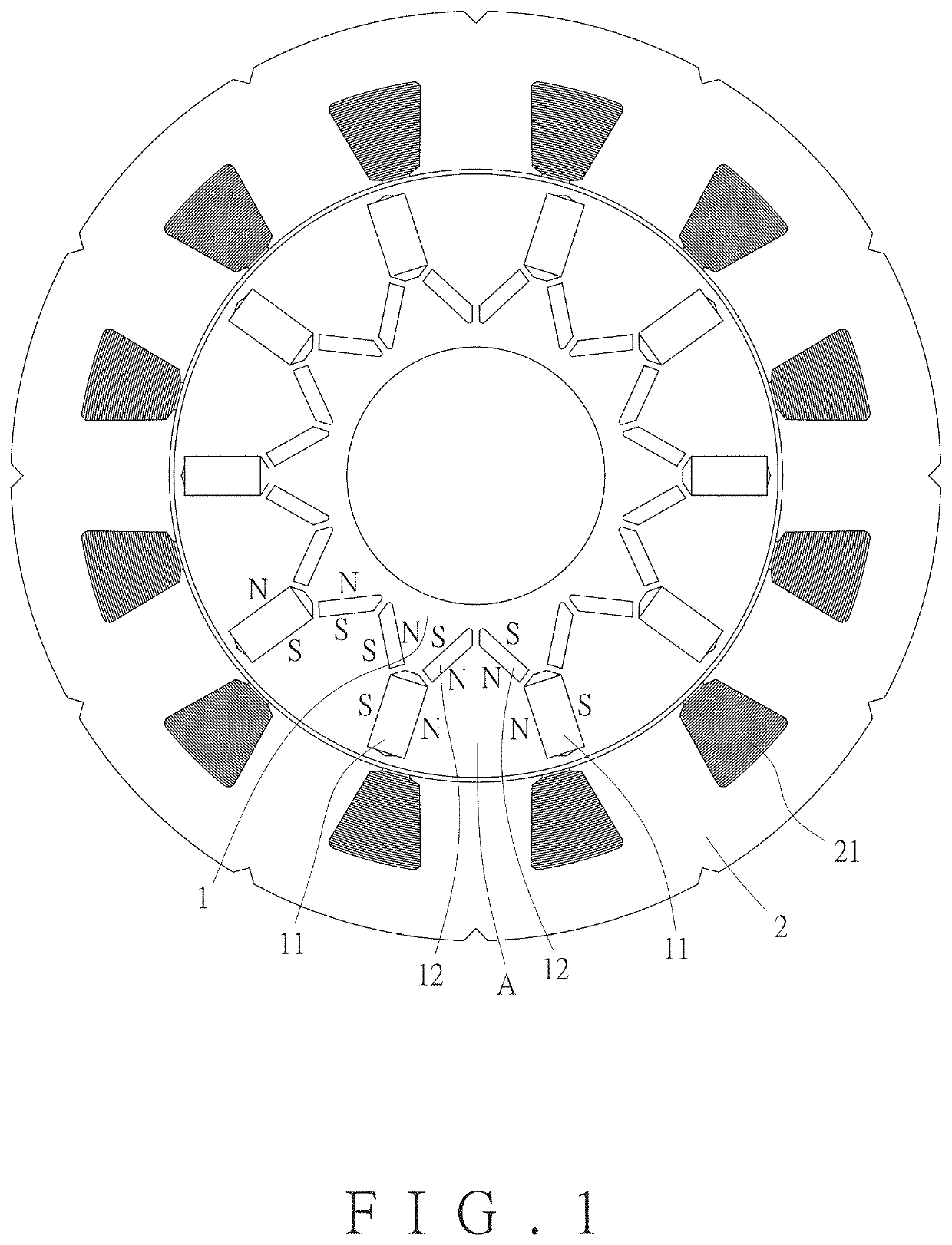

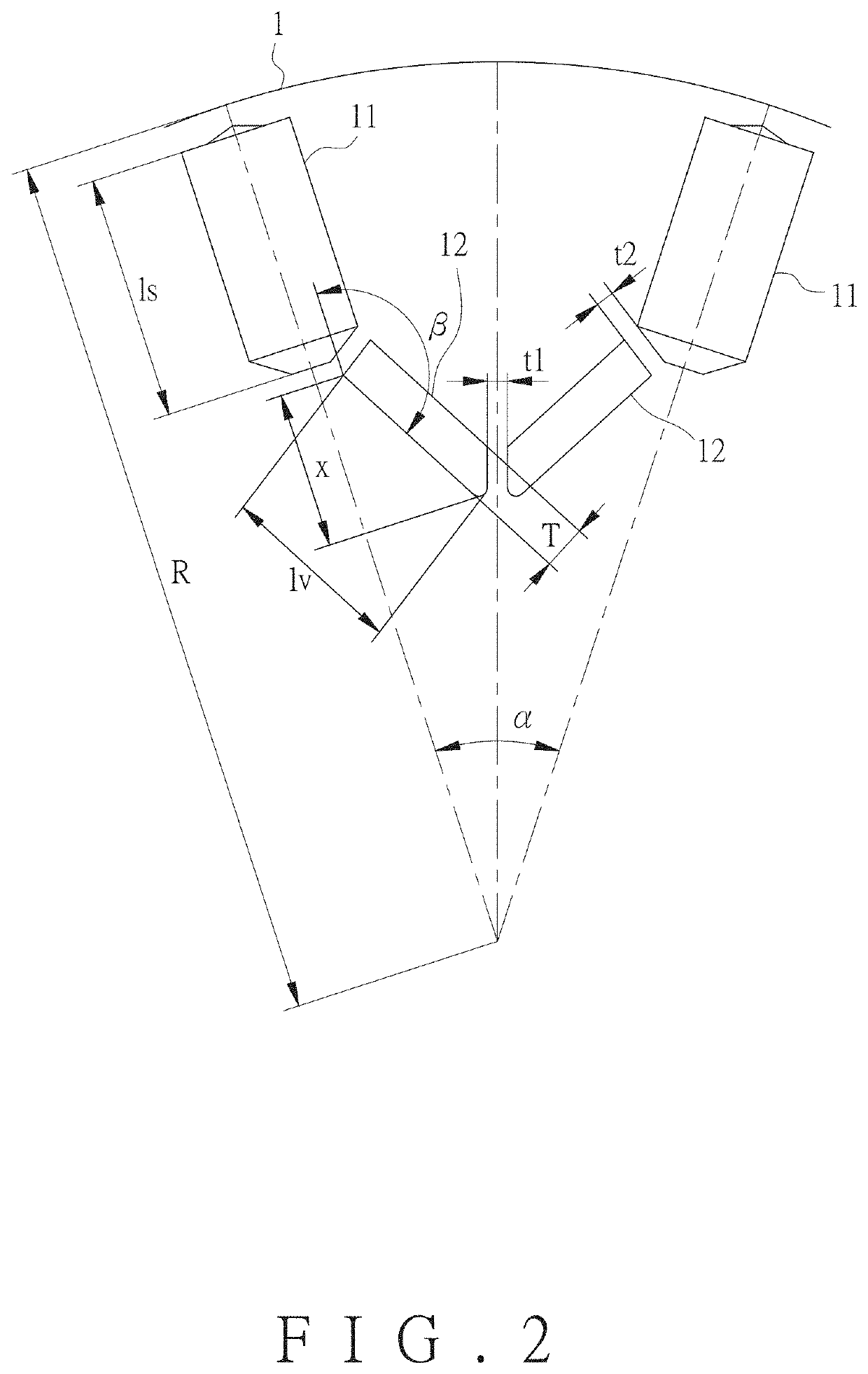

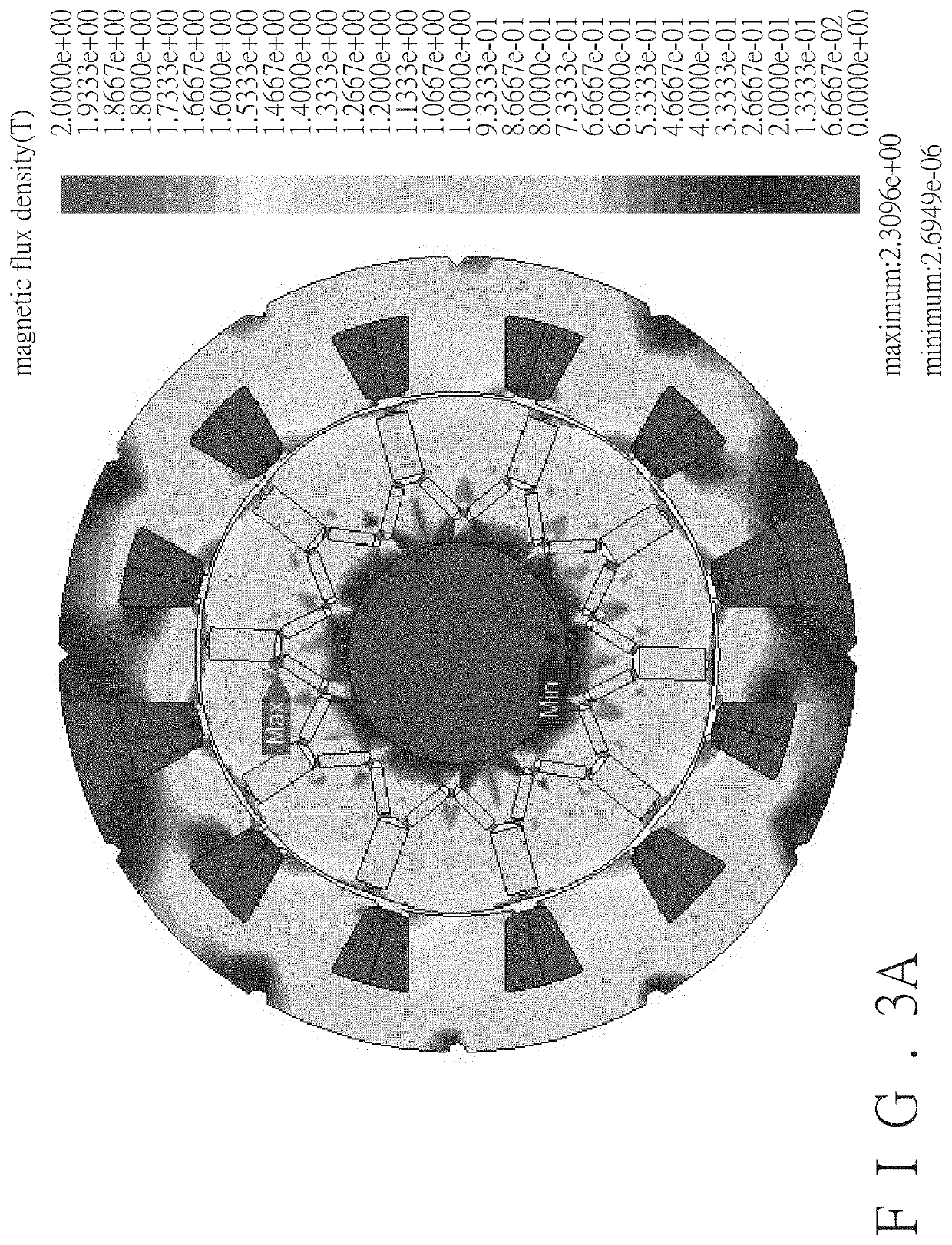

[0026]As shown in FIG. 1, a motor according to an embodiment of the present invention comprises a rotor core (1) and a stator core (2). The rotor core (1) has a plurality of spoke-type first magnetic members (11) that are arranged radially around the periphery of the rotor core (1). Two oblique second magnetic members (12) are provided between every adjacent two of the first magnetic members (11). The two second magnetic members (12) are arranged in a Vshape relative to the center of the rotor core (1). Every adjacent two of the first magnetic members (11) and the two second magnetic members (12) jointly surround an area (A). The first magnetic members (11) and the second magnetic members (12) face the area (A) with the same magnetic pole. The stator core (2) covers the rotor core (1). The stator core (2) has a plurality of stator windings (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com