Sanding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

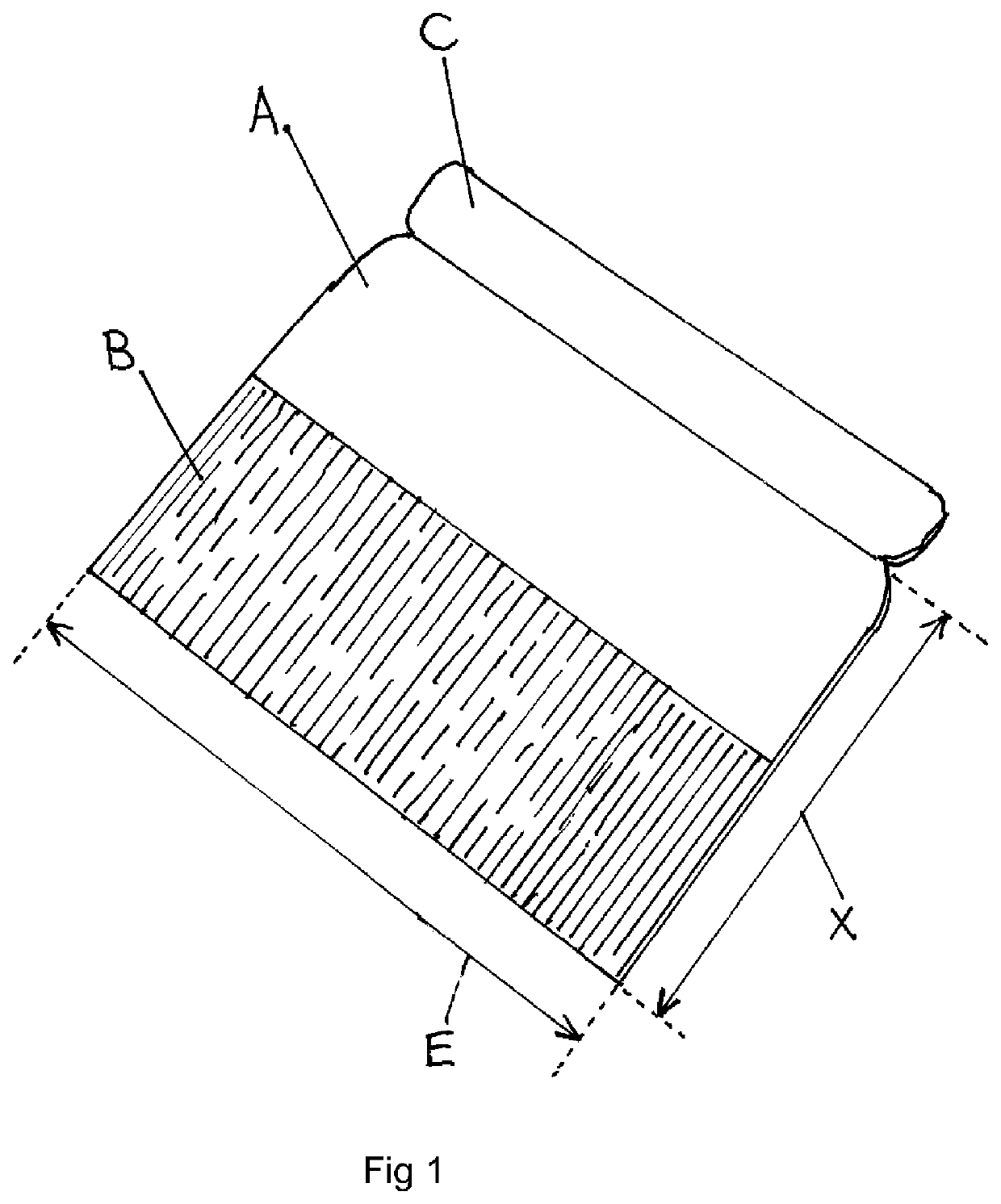

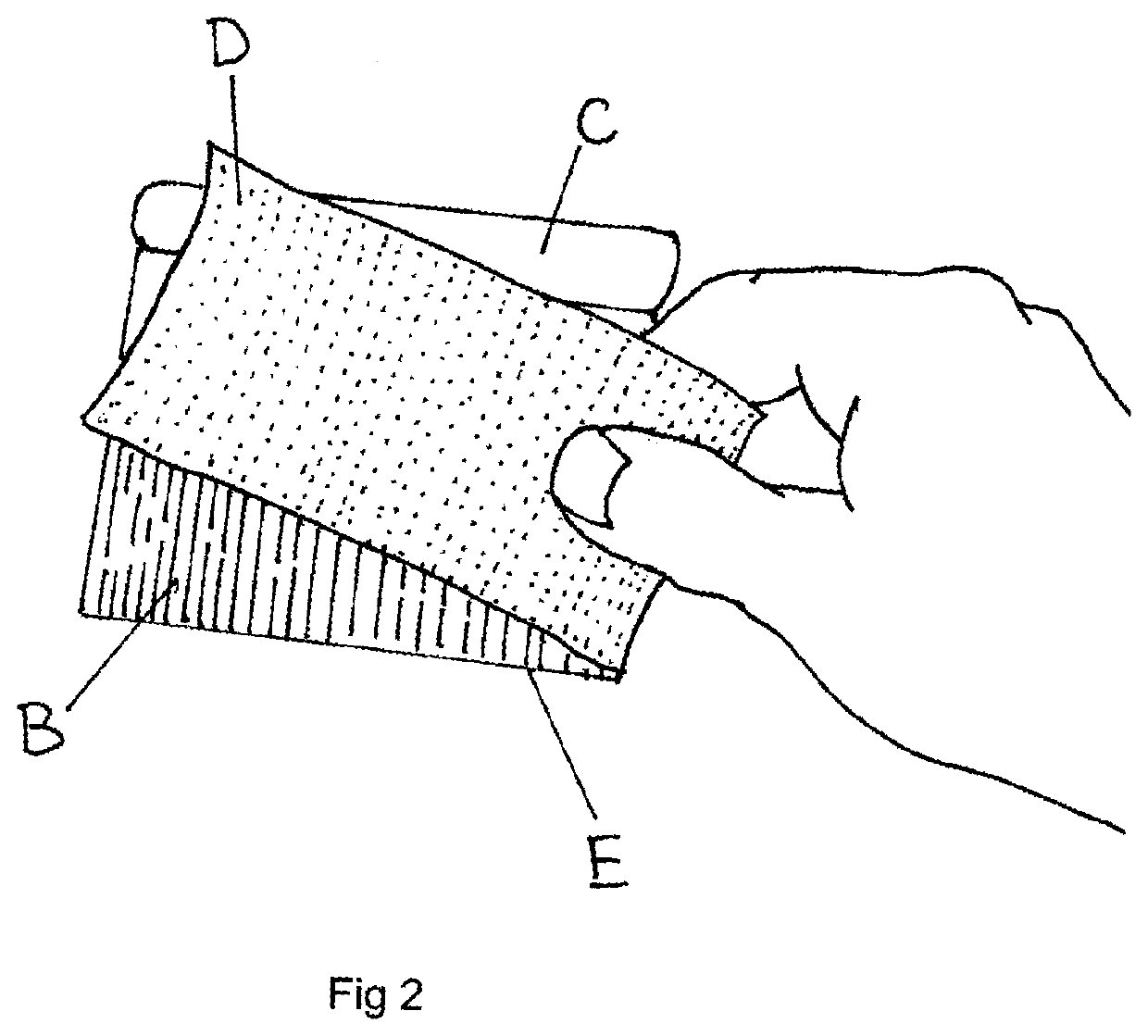

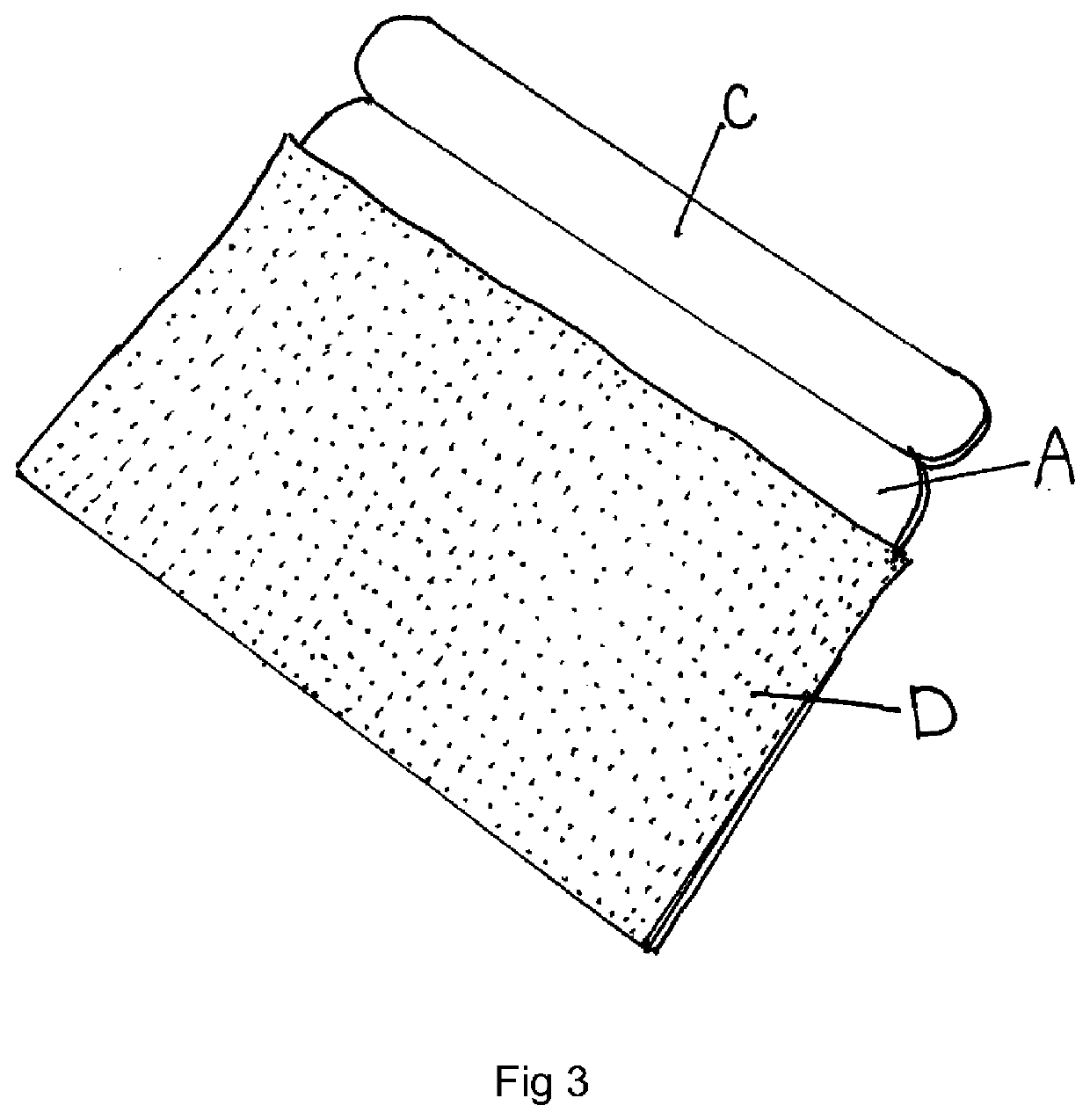

[0030]Referring to the drawings, FIG. 1 shows the sanding device according to the invention without any abrasive paper attached. The device comprises a generally rectilinear blade (A), formed of moulded polypropylene and having a 115 mm long edge (E), a 100 mm short edge (X) forming an angle 90° with the long edge (E) and a thickness of 1.5 mm, a hook fastener strip (B) that is the hook component of a hook & loop fastener and is permanently fixed to one side of the blade (A). The other side of the blade (A) is bare and has no hook fastener strip. Starting from the abrasive straight long edge (E), the hook fastener strip (B) extends across the full width of the blade (A) and to just over half the depth of the blade (A). This is preferable, although the hook element (B) could extend of the blade so that there is no flexibility in the blade across its width. The blade (A) is intended to only flex along the depth axis which runs between the abrasive edge (E) and the handle (C). The han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com