Crosscutter for web materials

a crosscutter and web material technology, applied in the field of web material crosscutter, can solve the problems of not being able to apply acceleration and deceleration, not being able to achieve the effect of large-area transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

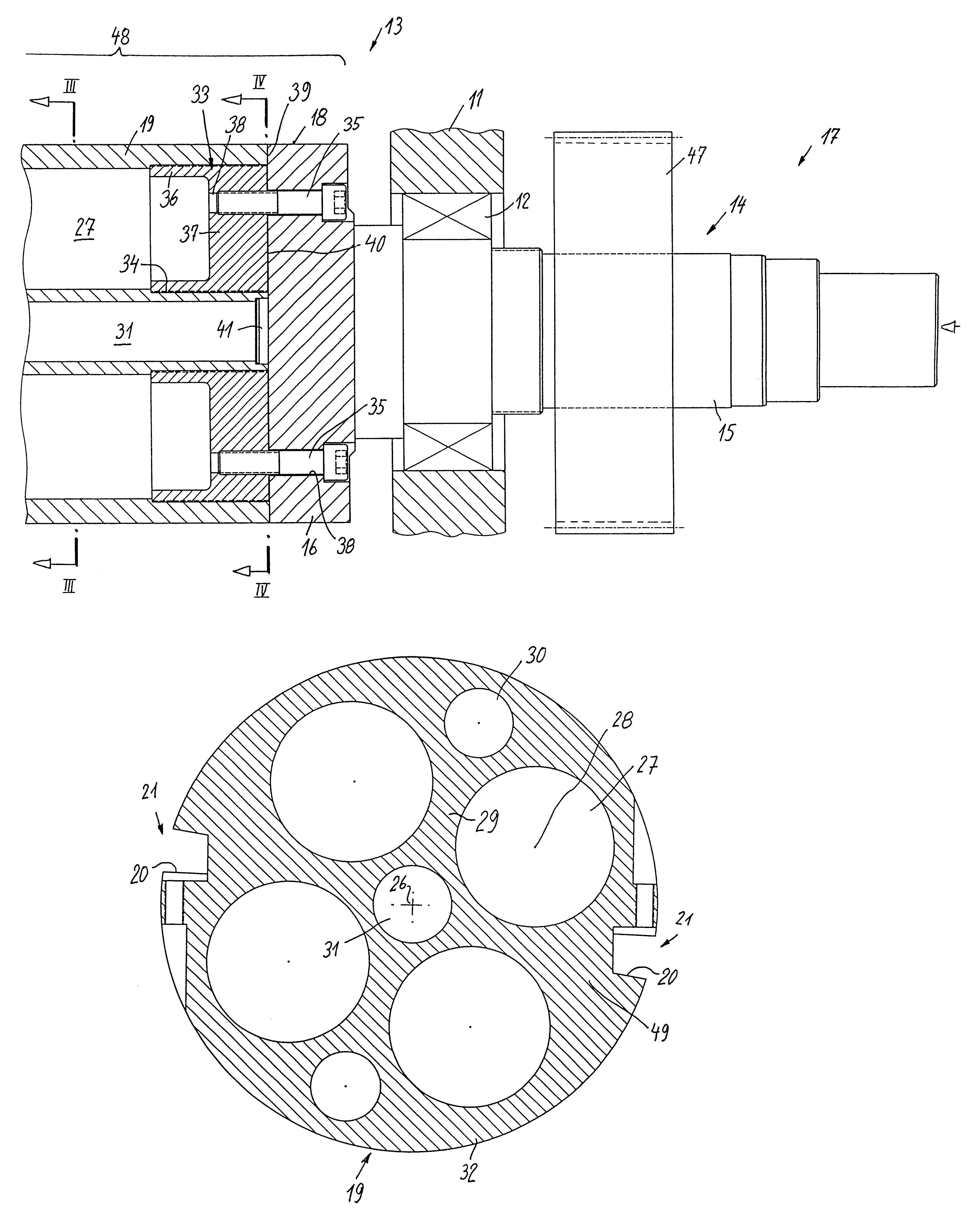

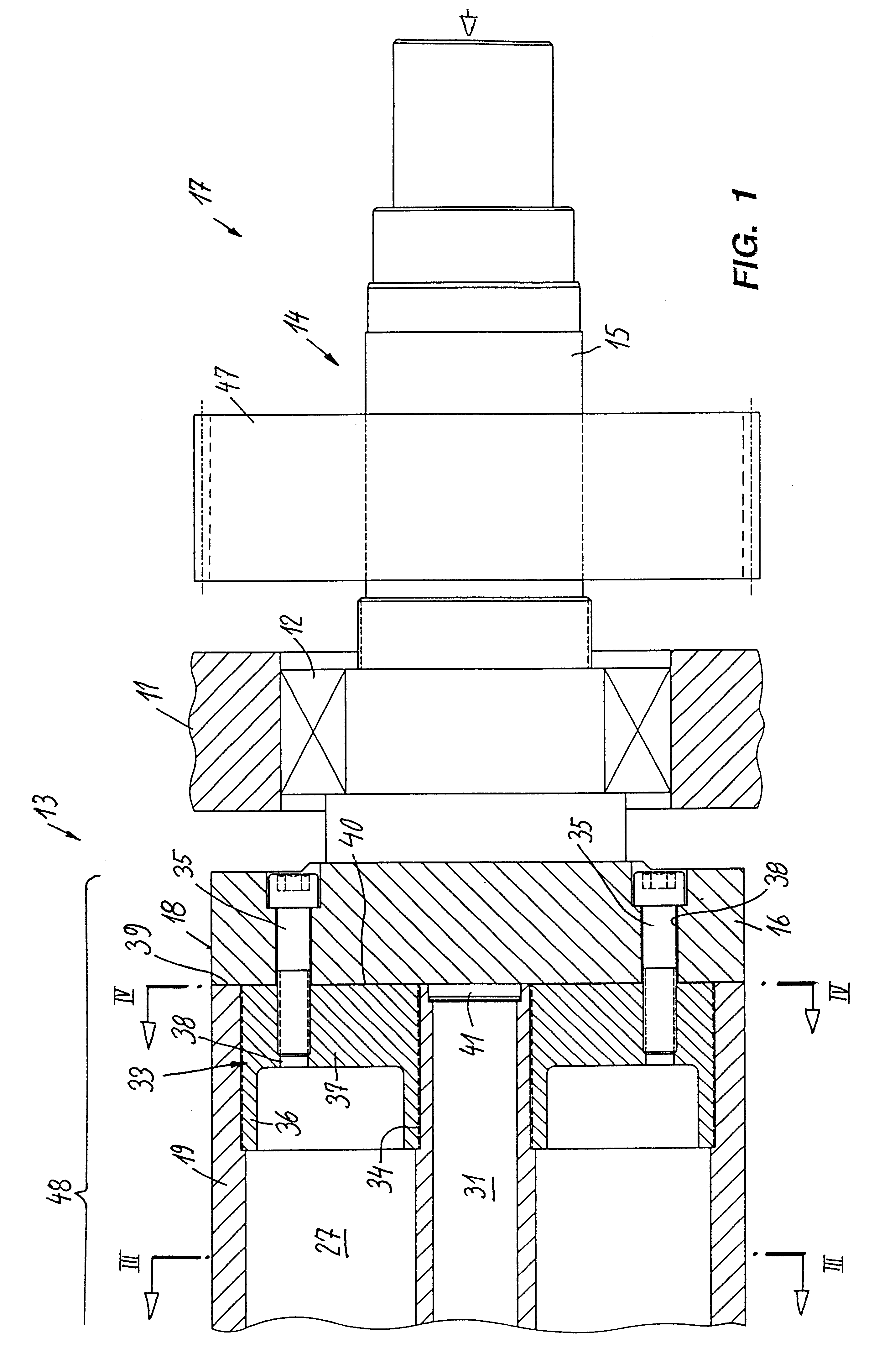

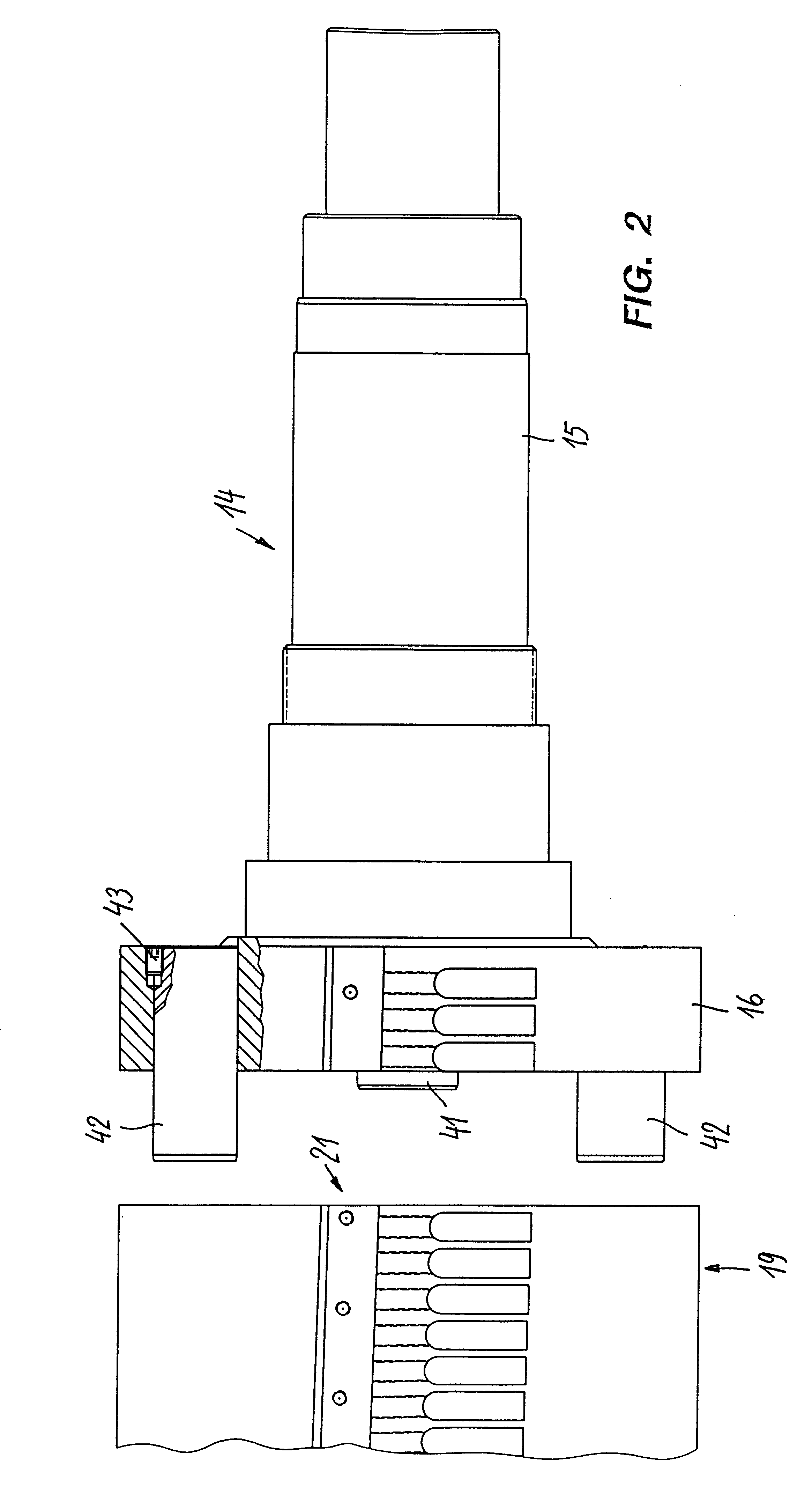

A cutter shaft 13 is mounted in bearings 12 in a crosscutter 11, whereof only part of the casing is shown and which is a so-called folio crosscutter. In conjunction with a corresponding, i.e. substantially identically constructed countercutter, it cuts from a web, which can comprise layers from different paper rolls, relatively large paper sheets, which are subsequently collected e.g. in reams or stacks on pallets.

On the shaft end 14 of the cutter shaft 13, which comprises a multistepped journal 15 and a flange 16 in one piece therewith (cf. FIGS. 1 and 2) acts a drive 17, to which belongs a synchronous gear 47, which is fitted in non-rotary manner on the journal. This gear meshes with a corresponding synchronous gear of the cutter shaft cooperating with the cutter shaft 13 shown. Generally synchronous gears are provided on both ends of a cutter shaft. The drive by the drive motors can either take place directly on the shaft journals 15 or by means of the synchronous gear. Generally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| web speed | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com