Vertical laser cavity with a non-planar top mirror

a laser cavity and non-planar top technology, applied in the direction of lasers, semiconductor lasers, optical resonator shape and construction, etc., can solve the problems of difficult fabrication and operation, low gain for each round trip, and inability to achieve lasing, so as to improve the optical performance of the laser cavity, reduce diffraction losses, and improve optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

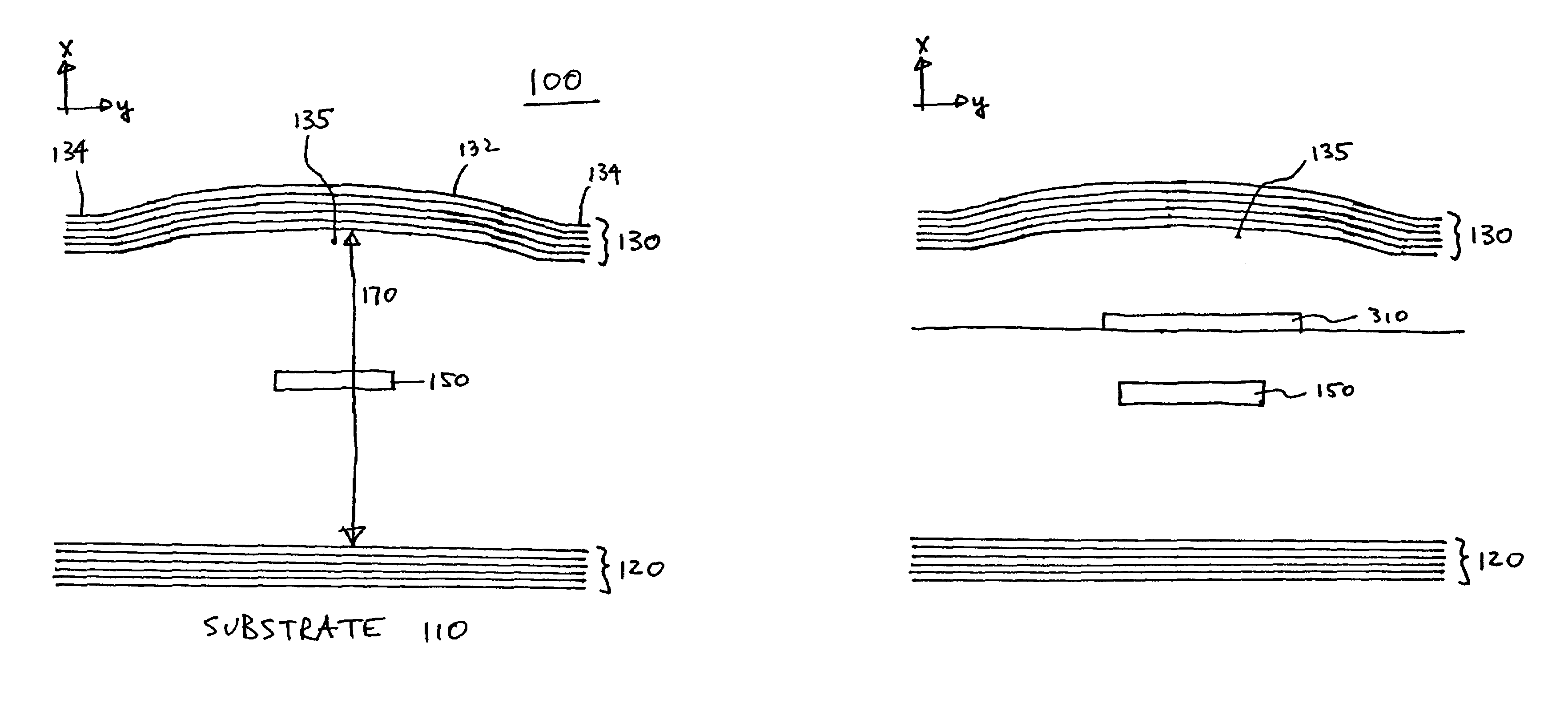

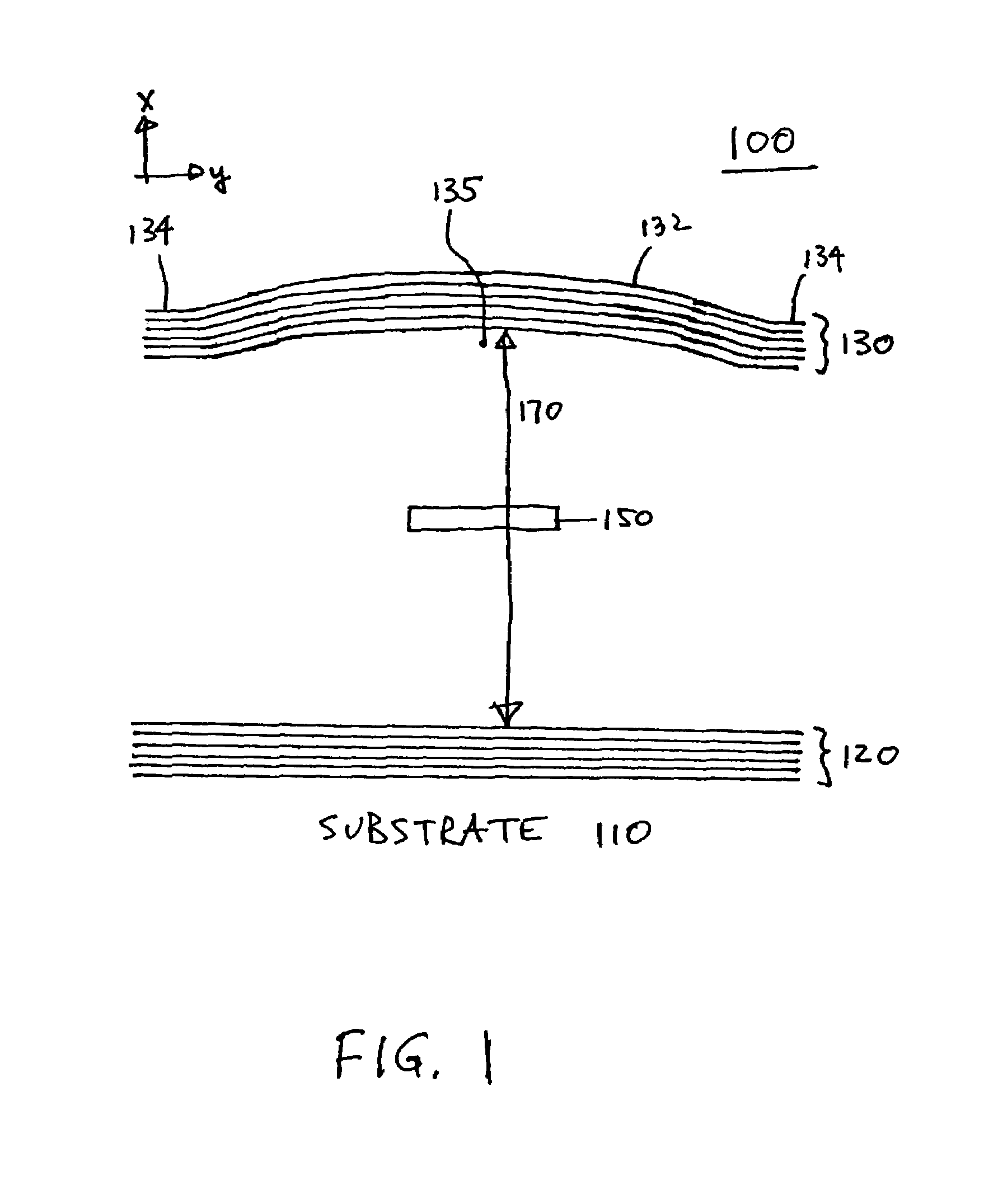

[0019]FIG. 1 is a cross-section of a vertical laser cavity 100 according to the invention. FIG. 1 is simplified to show only the relevant portions of the laser cavity 100. Other portions of the cavity (e.g., to achieve control over the laser mode, the pumping mechanism, etc.) have been omitted for clarity and can be designed using conventional techniques. The laser cavity 100 includes a bottom mirror 120 and a top mirror 130, and an active region 150 located in an optical path between the two mirrors 120, 130. The entire structure is fabricated on a substrate 110. It is vertical in the sense that the laser cavity 100 is oriented vertically with respect to the substrate surface. The laser cavity 100 is primarily a planar structure, but the top mirror 130 is non-planar. More specifically, the center portion 132 of the top mirror 130 is raised relative to the outer portions 134. In effect, there is a “bump”135 in the materials underneath the top mirror 130. Then, when the top mirror 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com