Method of tensioning a diaphragm for an electro-dynamic loudspeaker

a diaphragm and electro-dynamic technology, applied in the field of electro-dynamic loudspeakers, can solve the problems of frame design challenges, use of loudspeakers, and inability to position or orient the desired loudspeakers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

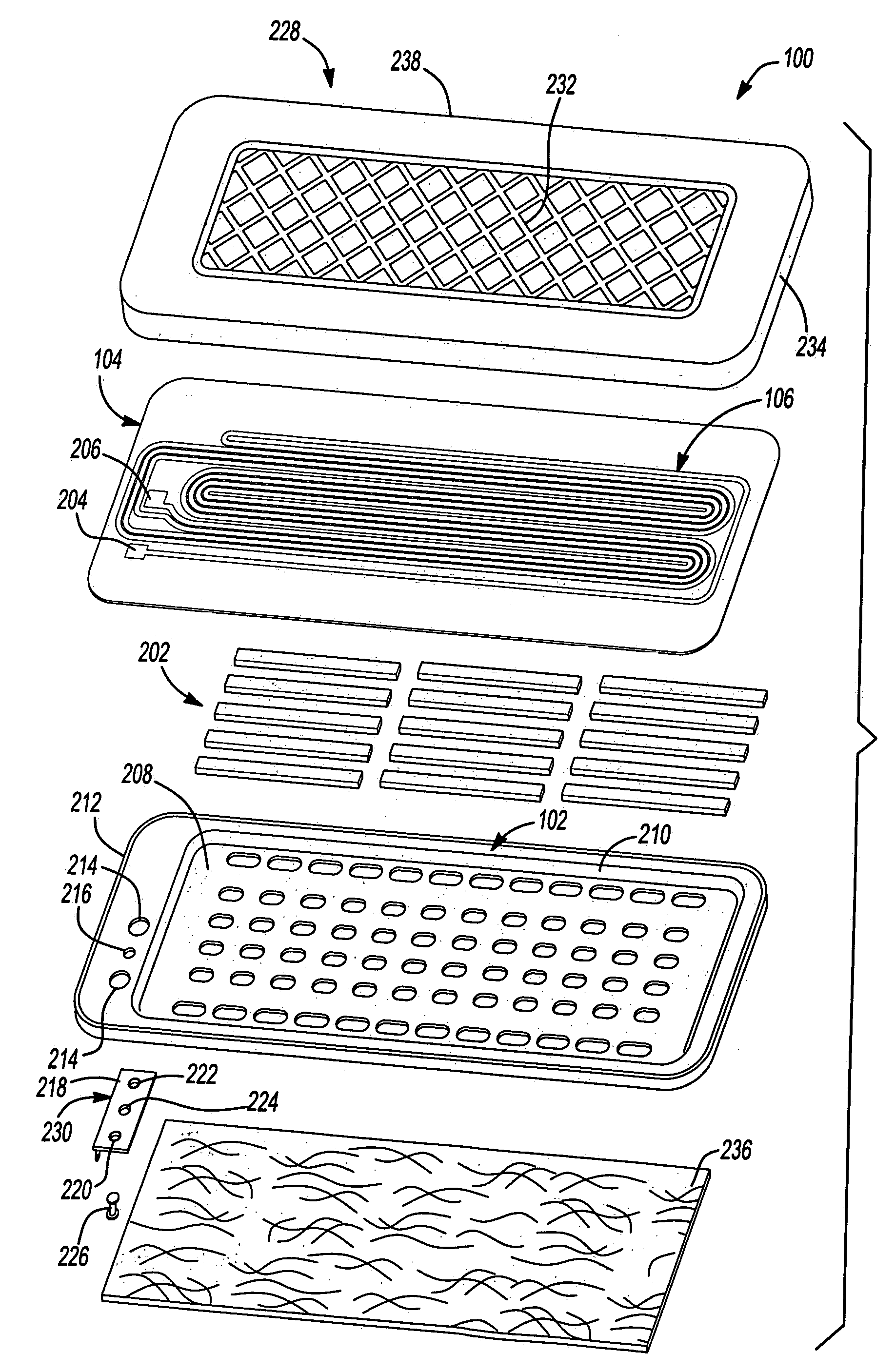

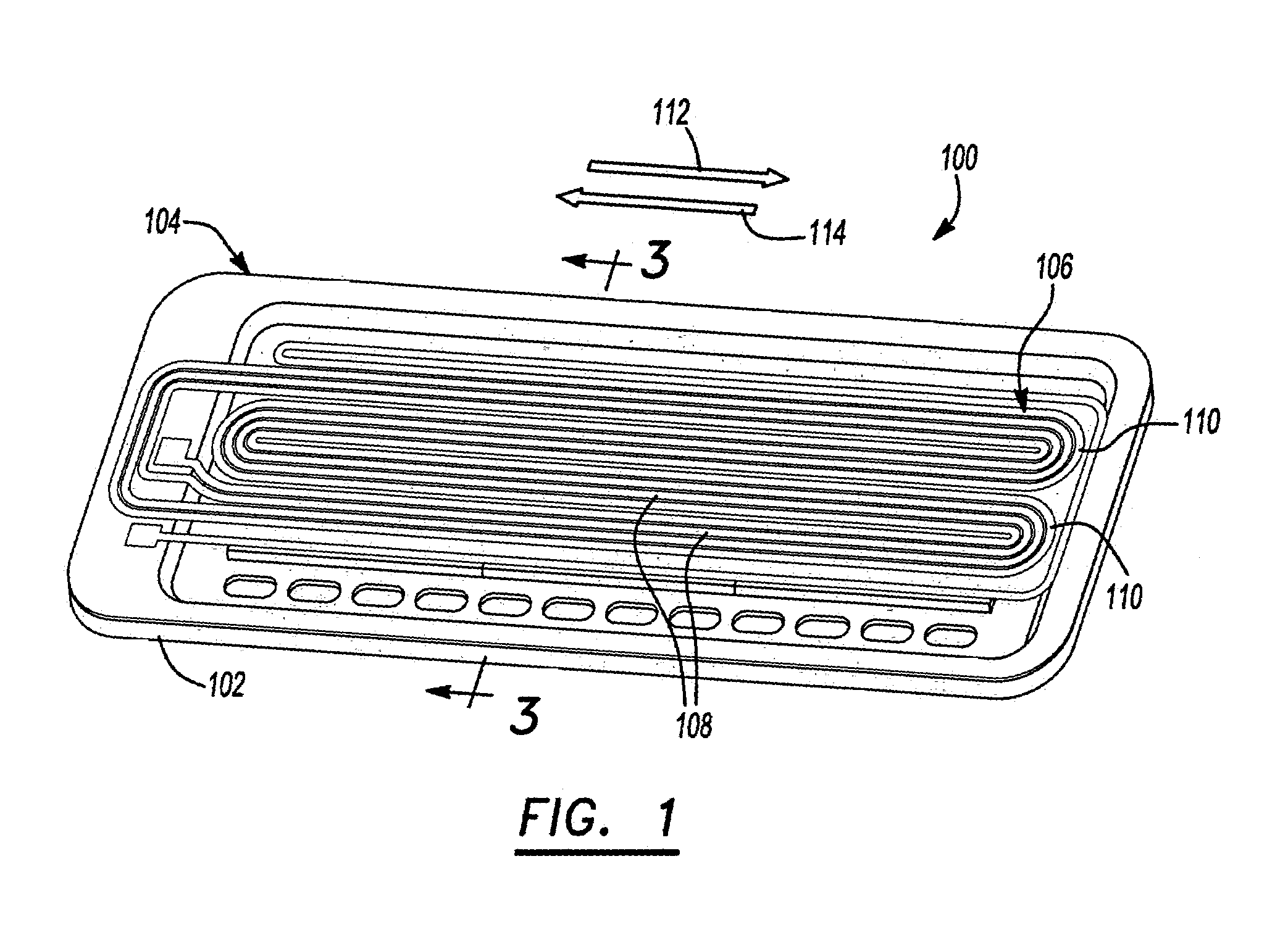

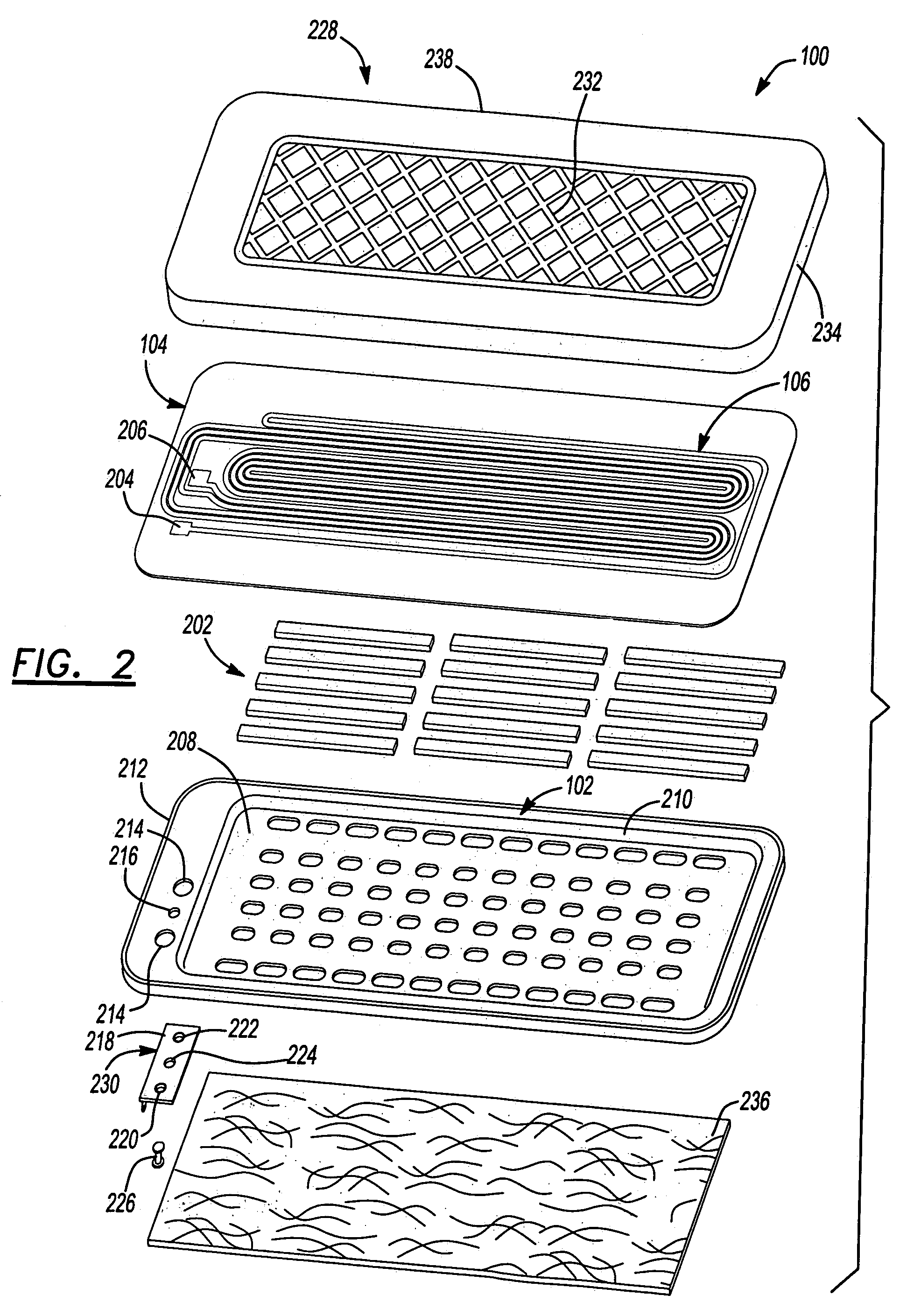

[0062]FIG. 1 is a perspective view of an electro-dynamic loudspeaker 100 of the invention. As shown in FIG. 1, the electro-dynamic loudspeaker is a generally planar loudspeaker having a frame 102 with a diaphragm 104 attached in tension to the frame 102. A conductor 106 is positioned on the diaphragm 104. The conductor 106 is shaped in serpentine fashion having a plurality of substantially linear sections (or traces) 108 longitudinally extending along the diaphragm interconnected by radii 110 to form a single current path. Permanent magnets 202 (shown in FIG. 2) are positioned on the frame 102 underneath the diaphragm 104, creating a magnetic field.

[0063]Linear sections 108 are positioned within the flux fields generated by permanent magnets 202. The linear sections 108 carry current in a first direction 112 and are positioned within magnetic flux fields having similar directional polarization. Linear sections 108 of conductor 106 having current flowing in a second direction 114, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com