Charger assembly for a power cell for an electrical tool

a technology of power cell and charger, which is applied in the direction of electric vehicles, electric generators, transportation and packaging, etc., can solve the problems of charger base (60/b>) to malfunction, users may be shocked,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

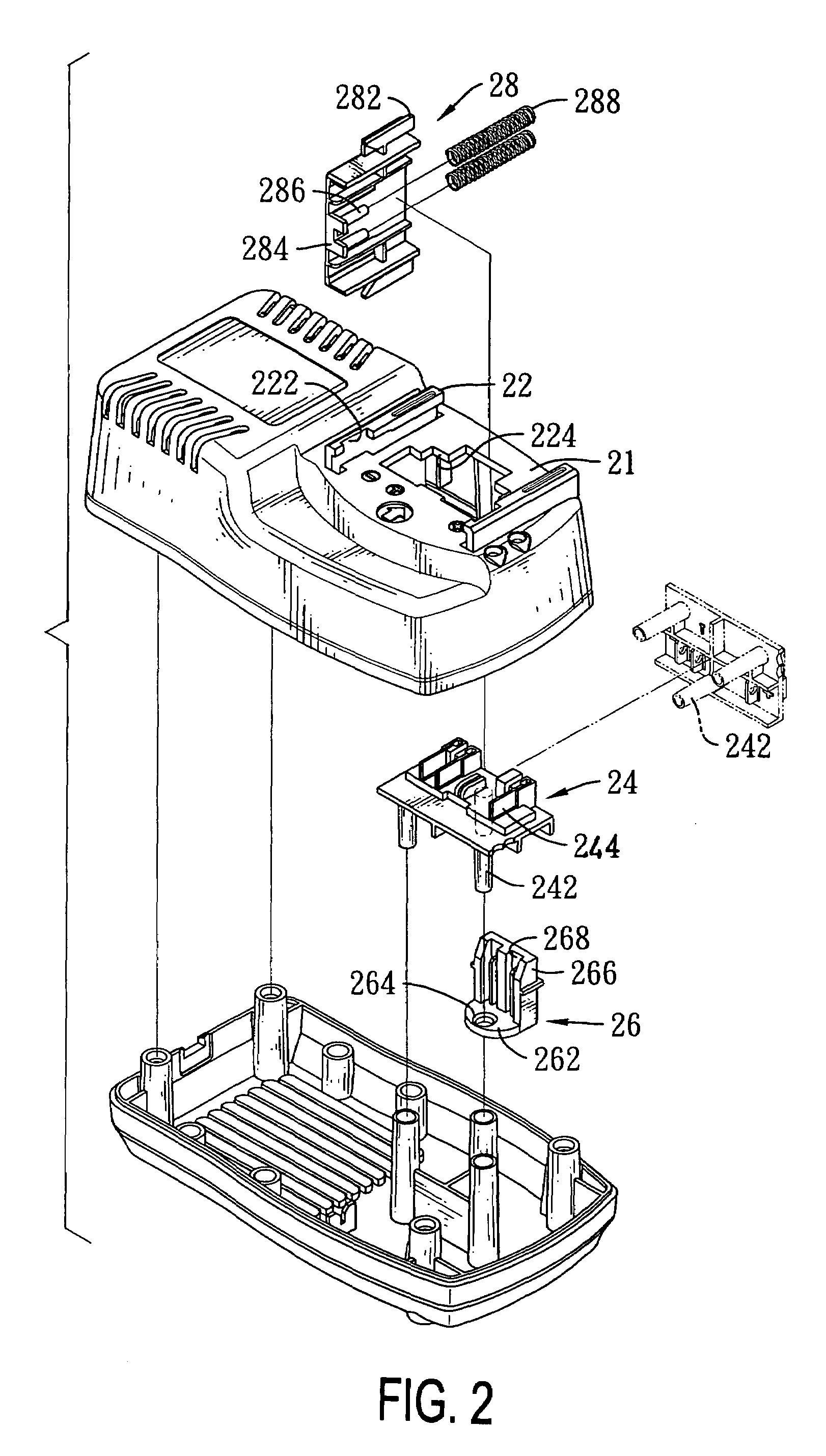

[0023]A charger assembly for a power cell for an electrical tool in accordance with the present invention comprises a power cell and a charger base. The power cell has two locking devices, and the charger base has a sliding cover selectively covering multiple electrodes. The locking devices allow the power cell to be firmly attached to and conveniently detached from the charger base. Additionally, the sliding cover protects the electrodes from rusting or becoming dusty when the power cell is not mounted on the charger base.

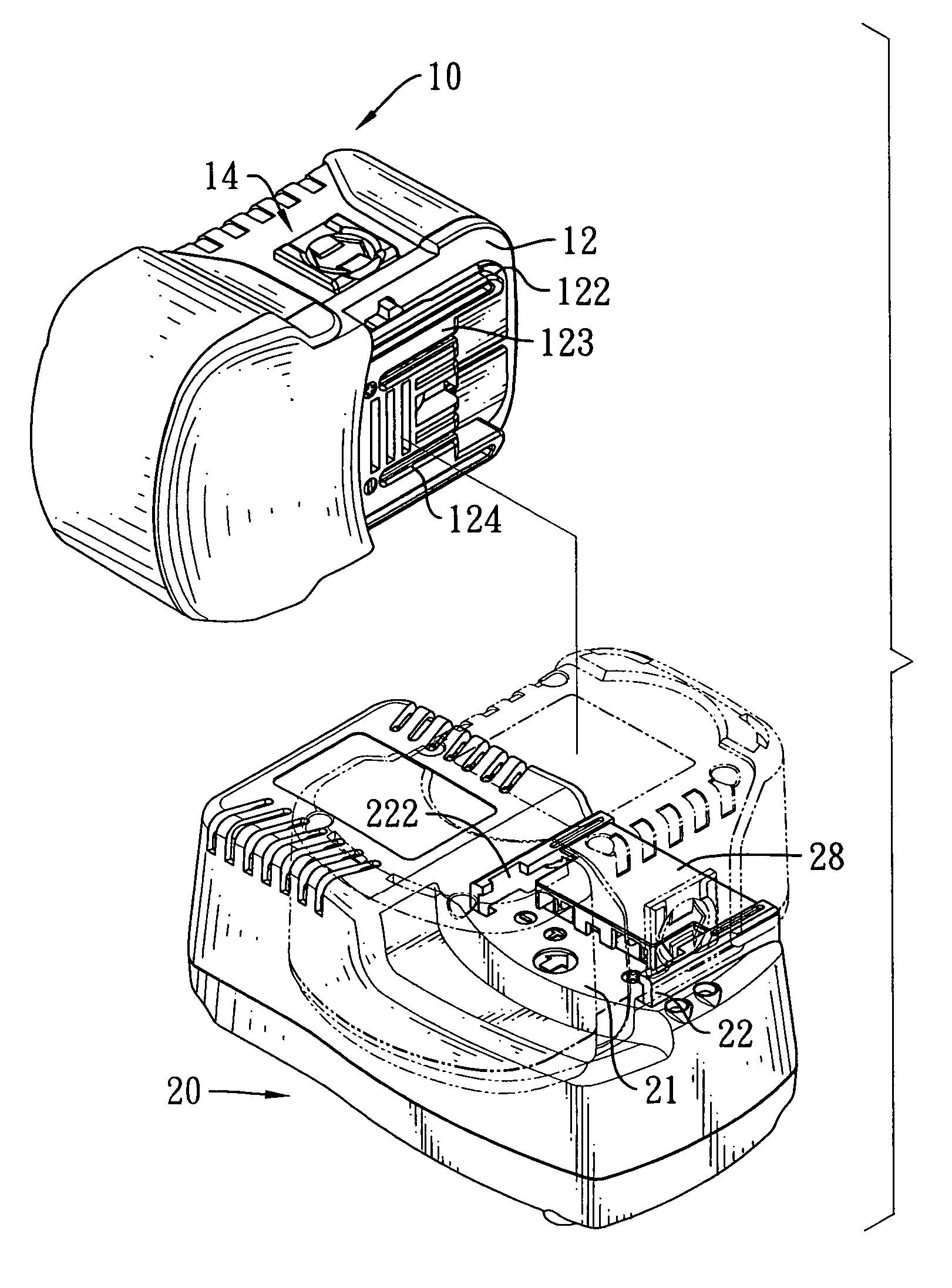

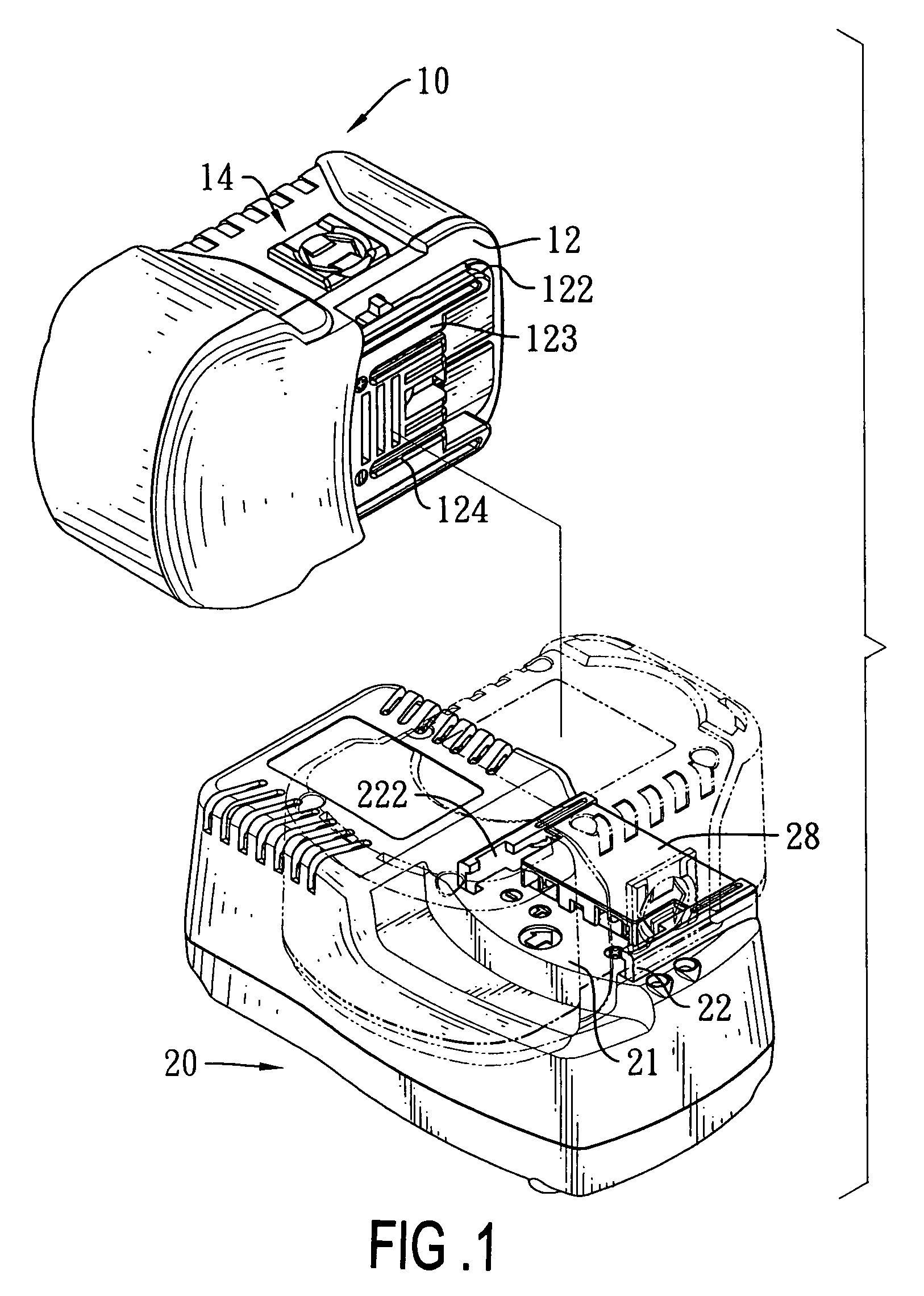

[0024]With reference to FIGS. 1 to 3, a preferred embodiment of the charger assembly for a power cell in accordance with the present invention comprises a power cell (10) and a charger base (20).

[0025]The power cell (10) has a box-like casing, two flanges (122), two through holes (126), a contact surface (123), multiple elongated electrodes (124) and two locking devices (14). The casing has a bottom contact face (12) and two sides. Each side has a mounting hole an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical continuity | aaaaa | aaaaa |

| electrical | aaaaa | aaaaa |

| electrical connection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com