Face seal with constriction ring

a sealing ring and sealing plate technology, applied in the field of shaft seals, can solve the problems of increasing frictional hysteria, loud seal squealing, squeaking, chirping or moaning noise, annoying vibration of the sealing ring, etc., and achieve the effect of preventing the impeller from overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the disclosure, its application, or uses.

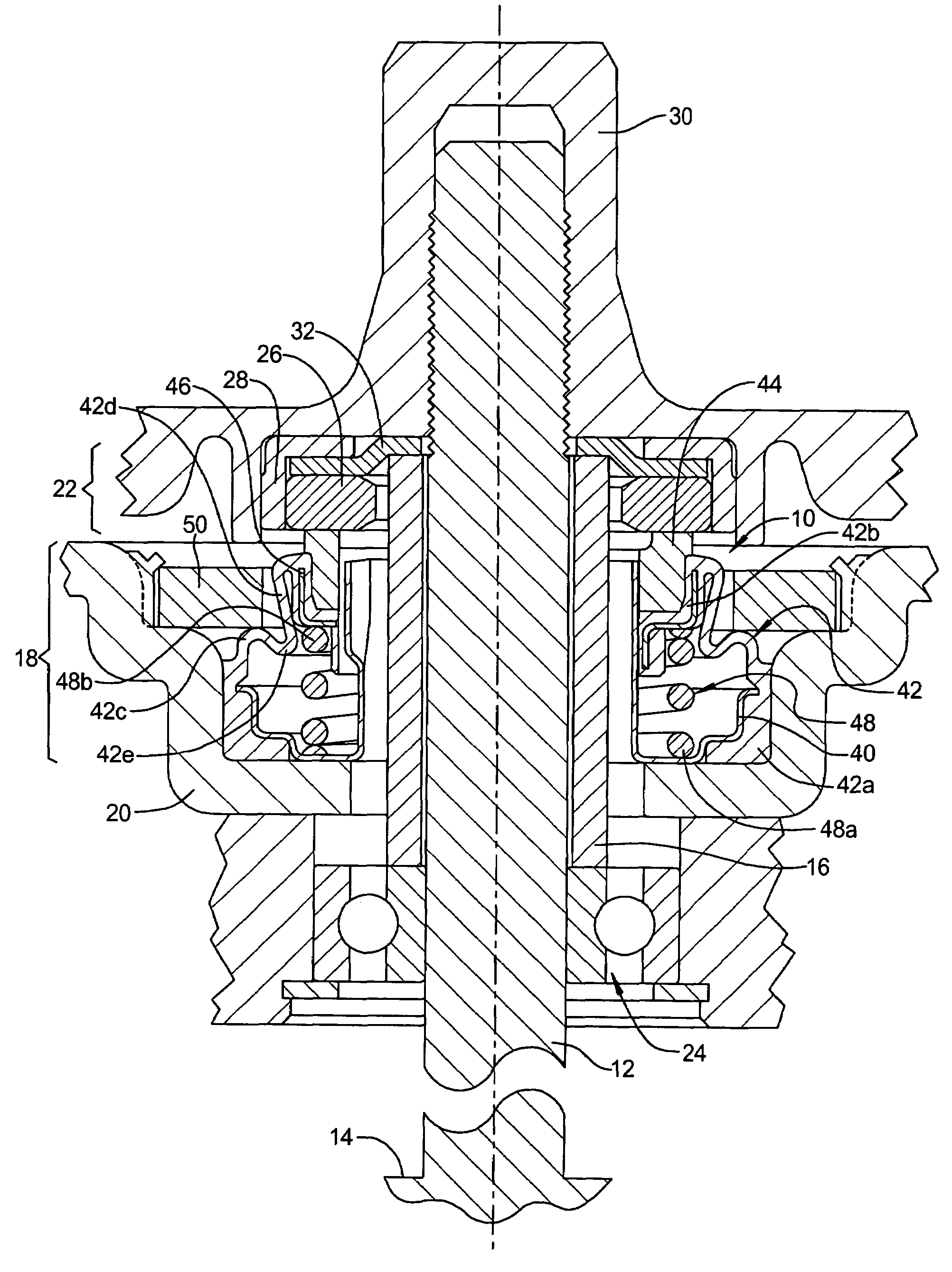

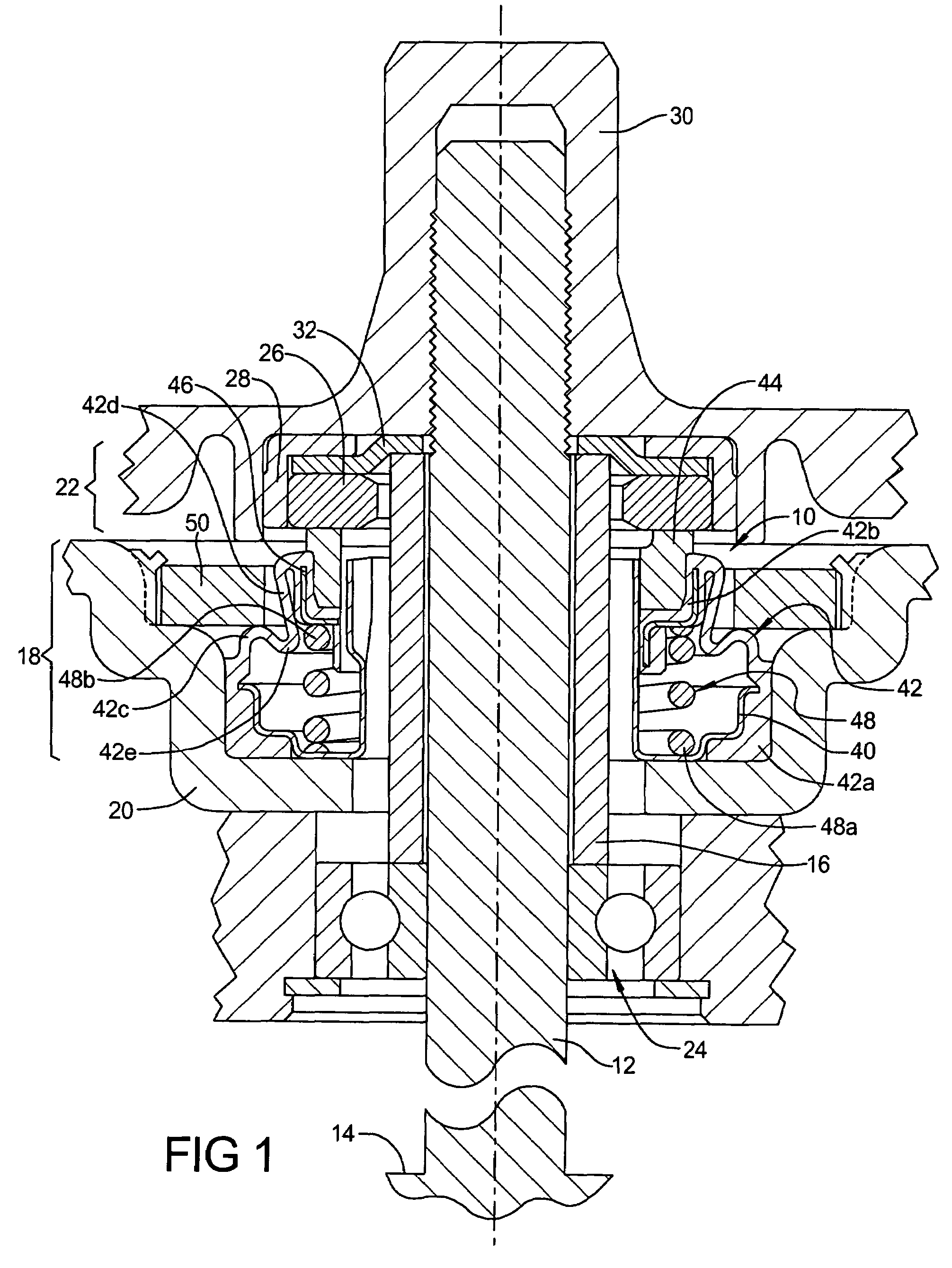

[0015]With reference to FIG. 1, a mechanical face seal assembly 10 is mounted about a rotatable shaft 12. The rotatably shaft 12 may be driven by, for example, a pump motor 14 in an automatic dishwasher, although the seal assembly 10 may be employed in other types of sealing applications for a rotatable shaft 12. The shaft 12 includes a shaft sleeve 16 mounted thereon. As an alternative to a shaft sleeve 16, the shaft 12 may have a shoulder formed thereon.

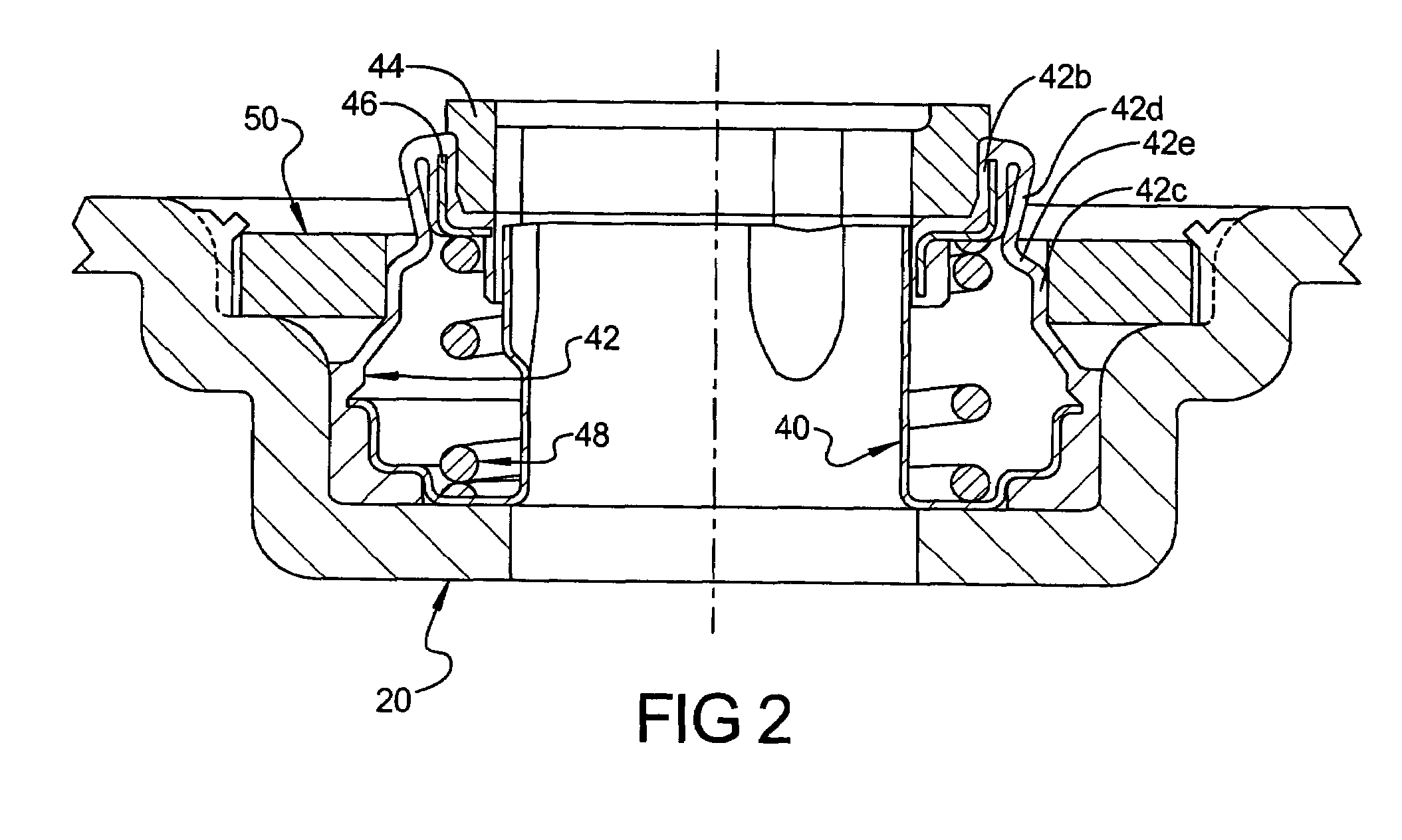

[0016]The seal assembly 10 includes a seal head assembly 18, mounted stationary relative to a pump housing 20, and a seal seat assembly 22, rotationally fixed to the shaft 12. A bearing 24 mounts to the shaft 12 with an inner race thereof abutting the shaft sleeve 16. The seal seat assembly 22 includes a seal seat 26 which abuts against the seal head assembly 18. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com