Tree remover

a tree and stump technology, applied in the field of excavating, can solve the problems of not having a wider use of materials for dwelling construction, a dangerous profession, and limited flexibility, and achieve the effects of safe and easy tipping and removal of trees and stumps, reducing the cost of purchase and maintenance, and improving access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

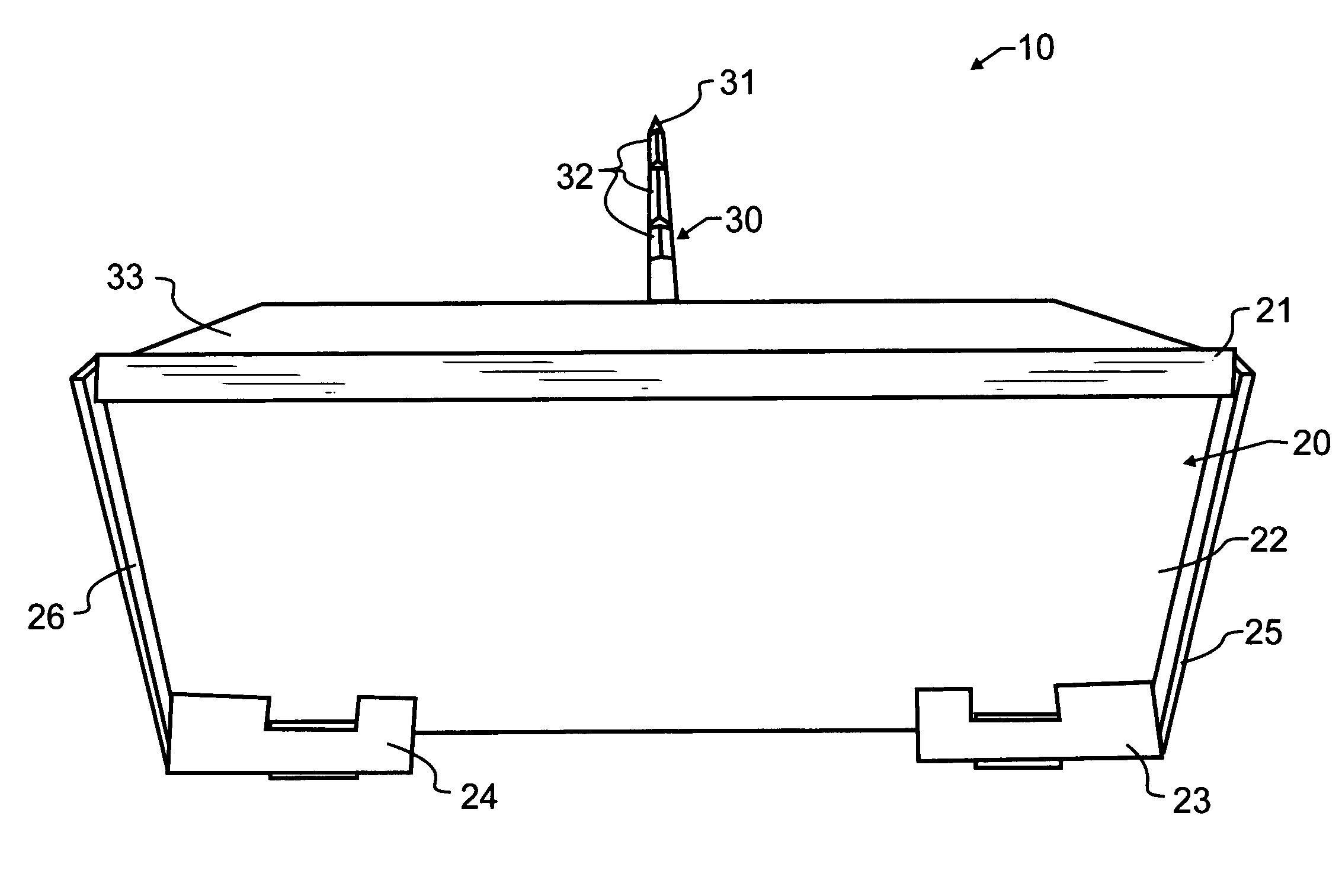

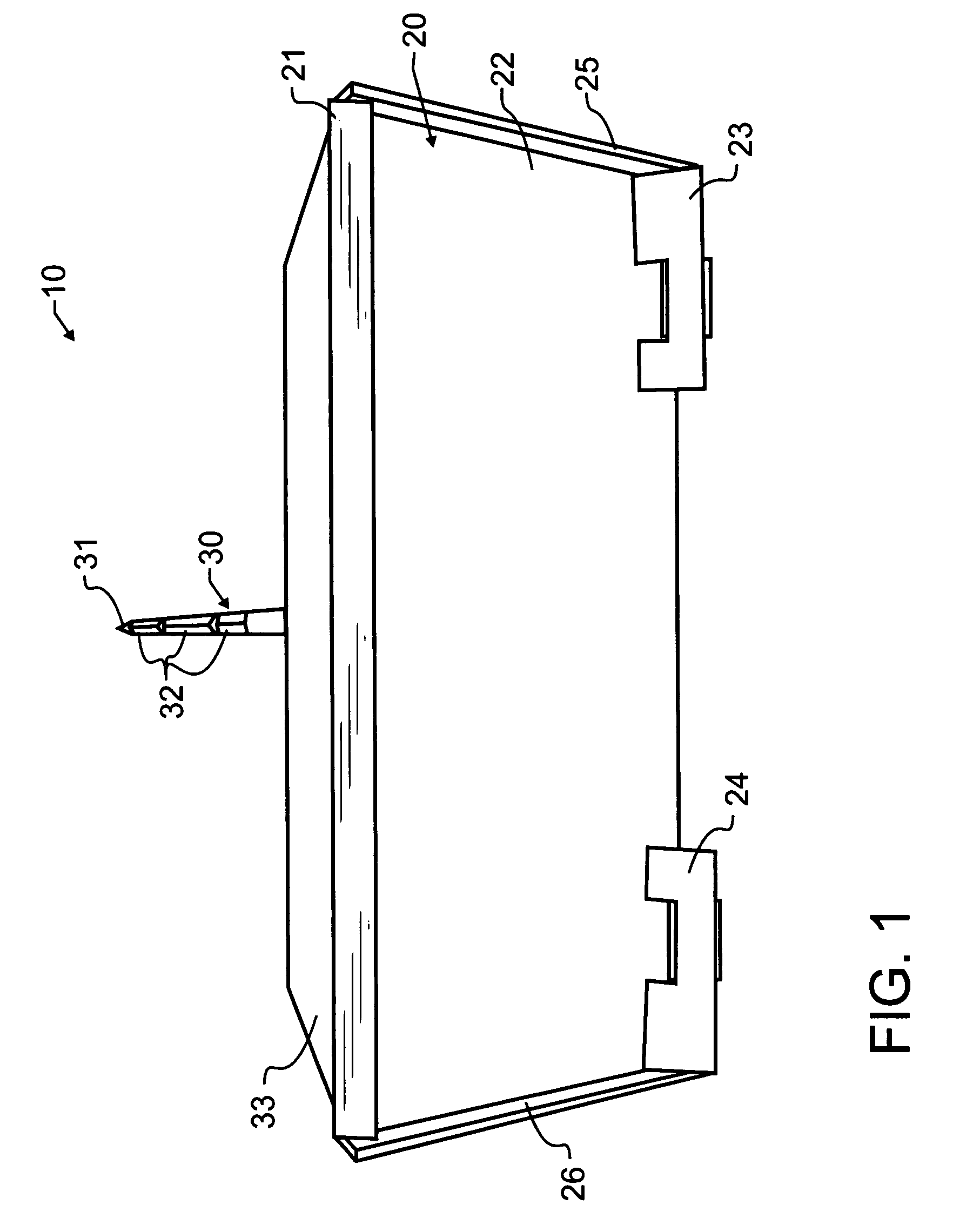

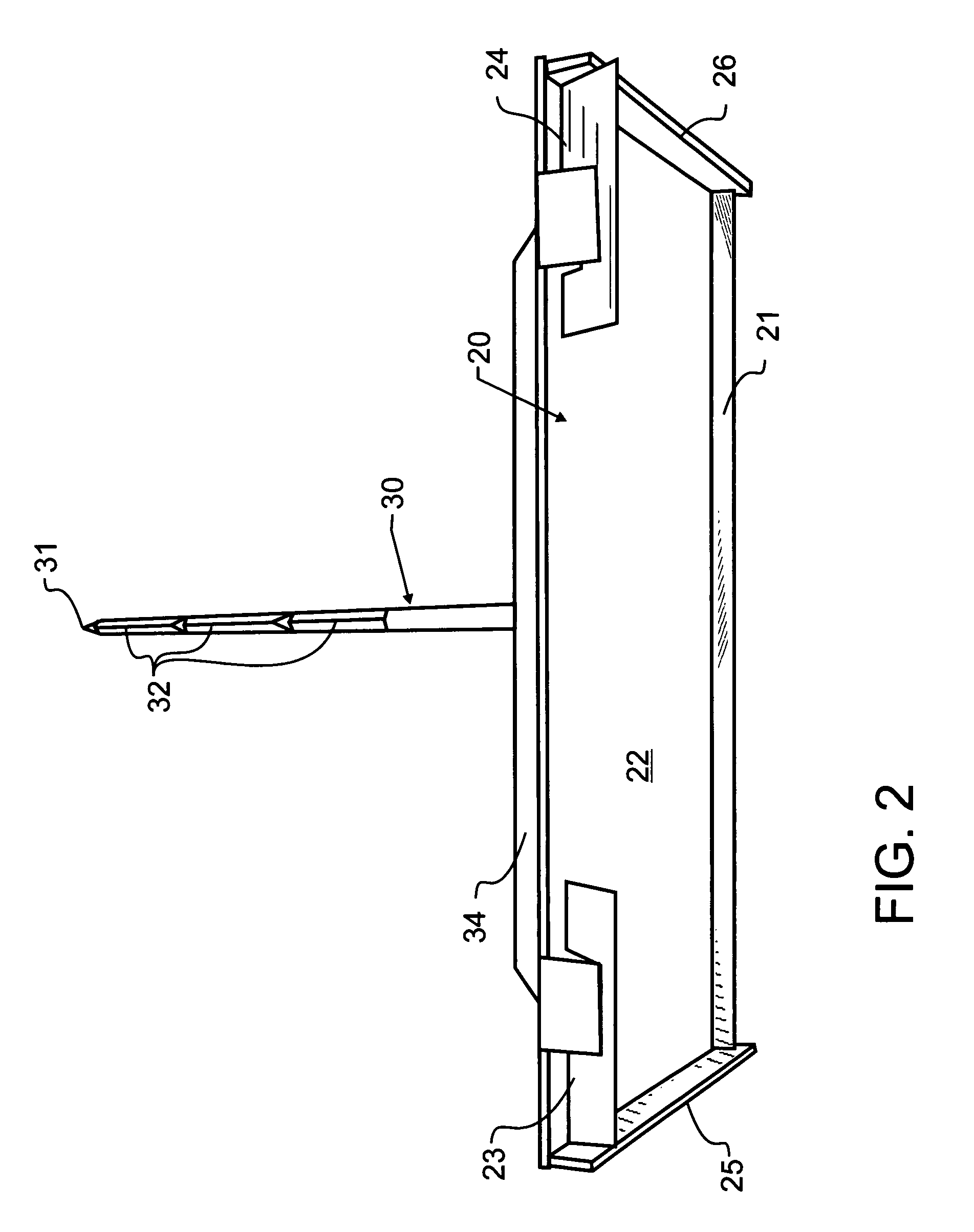

[0027]Manifested in the preferred embodiments illustrated herein and each of the alternatives disclosed, implied, or that may readily be recognized by those reasonably skilled in the art, the present invention provides an apparatus and method which overcomes the limitations of the prior art recognized herein above. In demonstration thereof, and as required by and in compliance with the federal patent statutes, FIGS. 1-3 illustrate a first preferred embodiment tree remover apparatus 10, which includes a coupler 20 adapted for quick attachment to and removal from a skid steer or like vehicle. Coupler 20 includes a top lip 21, a flat plate 22, and quick coupler members 23, 24. Sides 25 and 26 complete the coupler. Extending forward from tree remover apparatus 10, in the normal direction of forward travel for a front-mounted attachment, is knife 30. Knife 30 is preferably mounted generally central to tree remover apparatus 10, to permit usage on either or both sides of a tree. It will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com