Metallic linkage-type keying device

a keying device and metal linkage technology, applied in contact mechanisms, display/control units, dental surgery, etc., can solve problems such as low cost, external damage of semiconductor elements, and inability to disable electronic products, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The present invention pertains to a design of a metallic linkage-type keying device, wherein plastic keys are directly assembled to a metallic linkage. The present invention may apply to various electronic devices, such as cameras, mobile phones and video cameras. Below, the present invention is to be exemplified with its application in a camera.

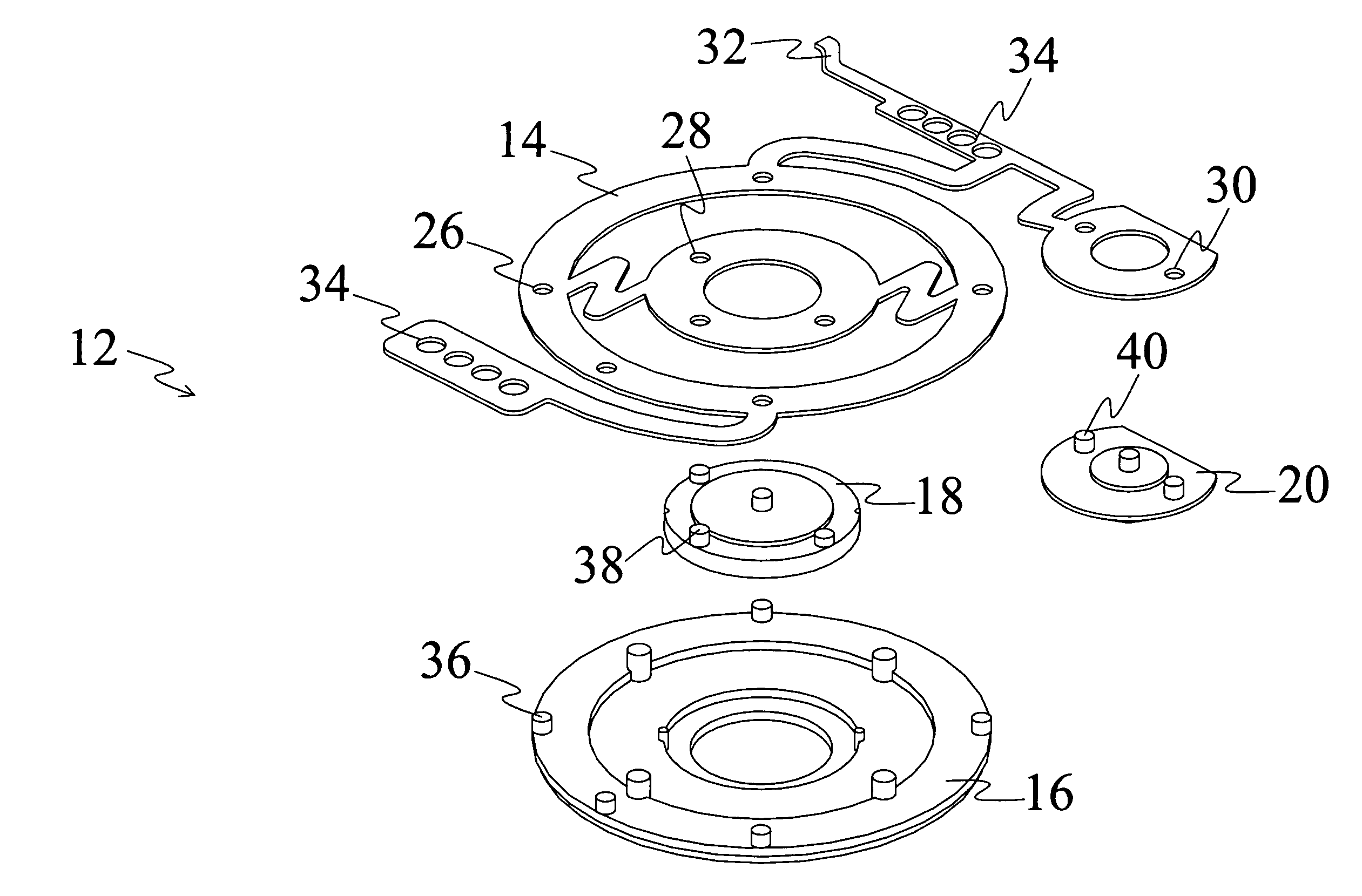

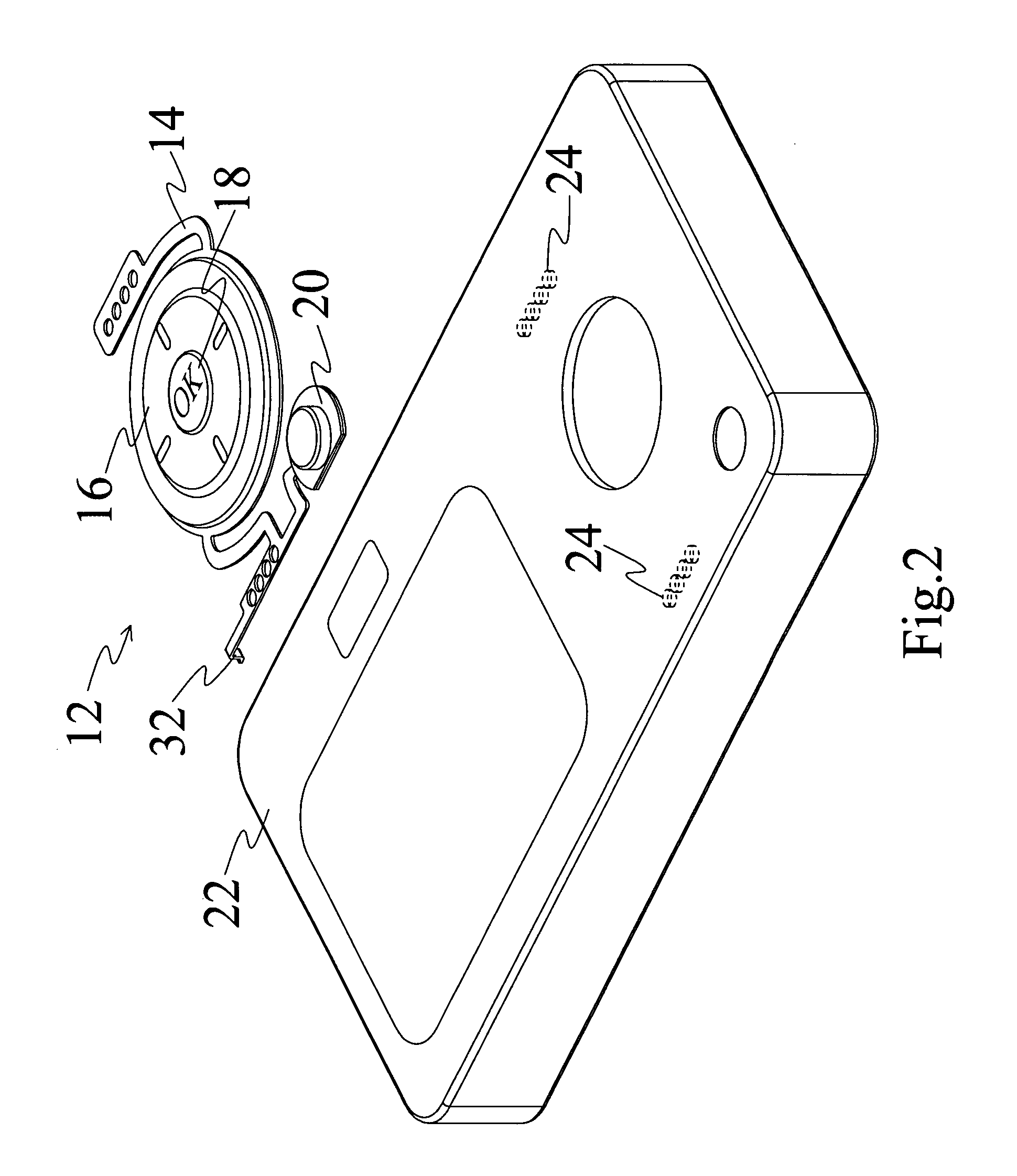

[0017]Refer to FIG. 2 a perspective view schematically showing the metallic linkage-type keying device according to the present invention before it is assembled to a camera casing. As shown in FIG. 2, the metallic linkage-type keying device 12 according to the present invention comprises: a metallic linkage 14; and three keys 16, 18 and 20, made of a plastic material. The camera casing 22 has eight heat-fusion protuberances 24, functioning as connecting portions. Refer to FIG. 3 an exploded view of the metallic linkage-type keying device according to the present invention. As shown in FIG. 3, the metallic linkage 14 has five heat-fusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com