Method for manufacturing a dental restoration

a technology for dental restorations and manufacturing methods, which is applied in the direction of dental prosthetics, additive manufacturing, dental preparations, etc., can solve the problems of increasing the shrinkage of bound ceramic powder, unable to predict shrinkage in all directions, and not being able to use this technology in dental restoration applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

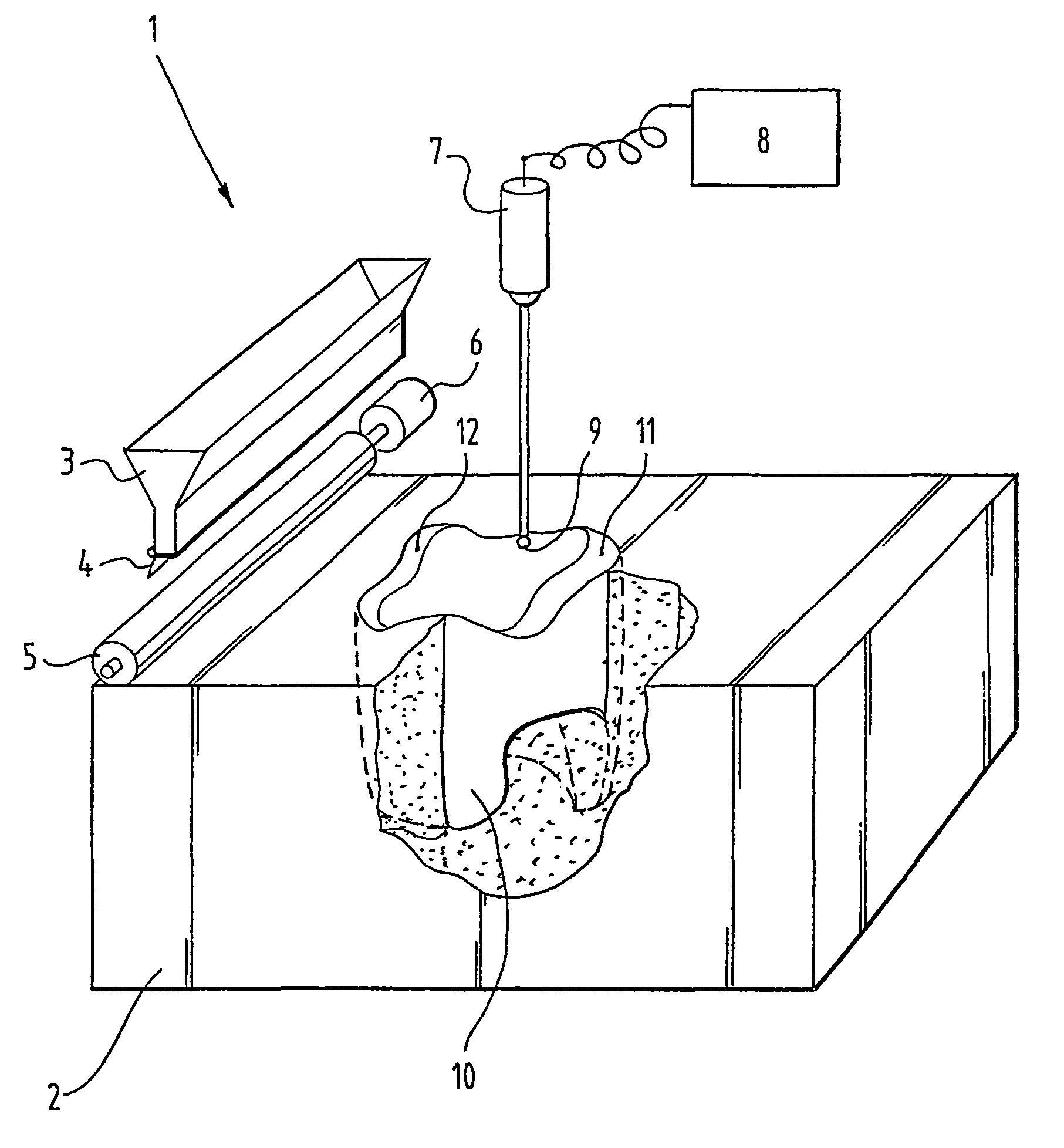

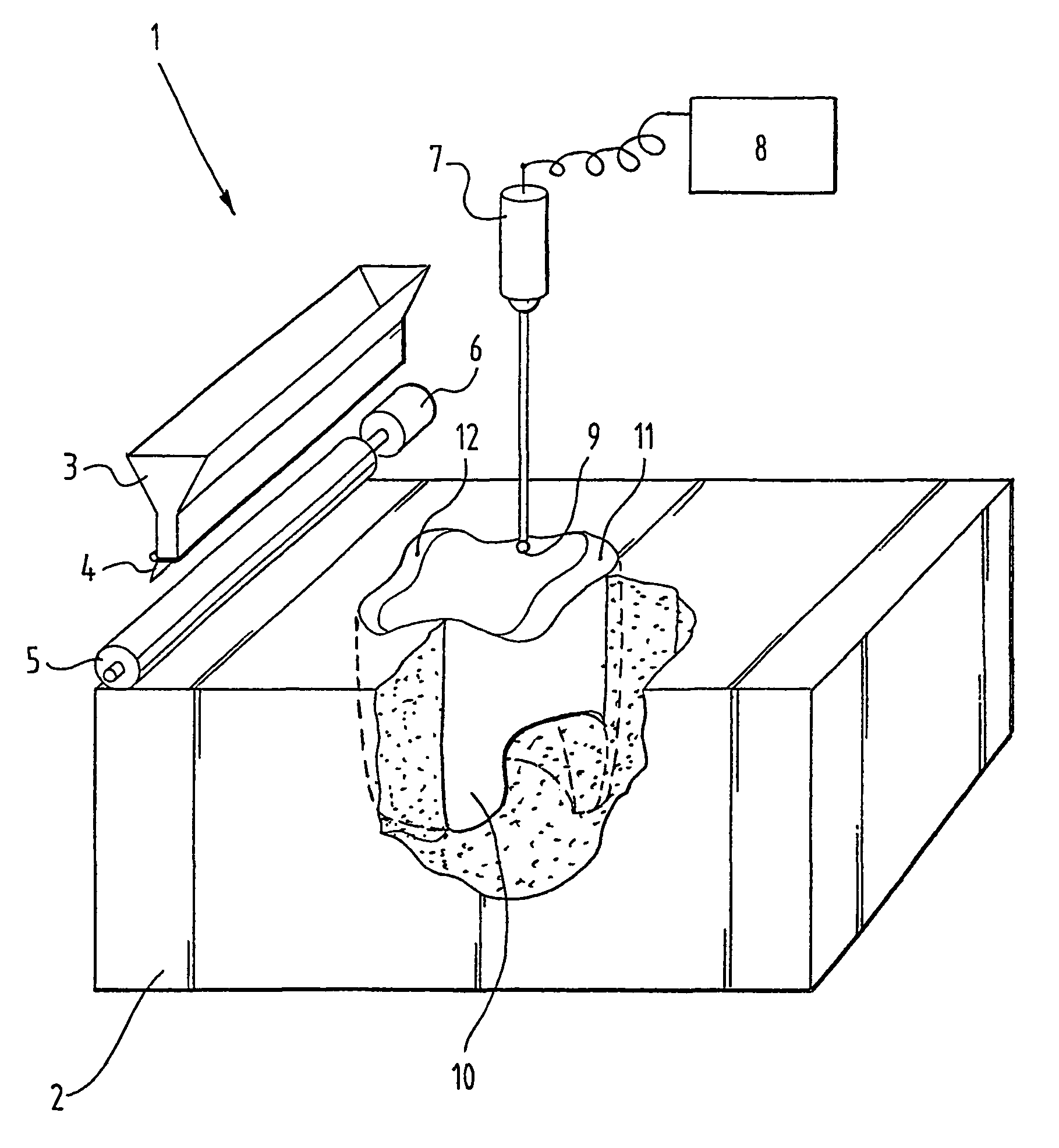

[0027]Installation 1 comprises a holder (not shown) in which layers of powder-form yttrium-stabilized tetragonal zirconium oxide (Y-TZP) can be placed one over another. The zirconium oxide is in powder form so that a body 2 of this powder is formed as the stacking of said layers onto each other progresses.

[0028]The layers are arranged using a powder holder 3, which in this embodiment is funnel-shaped and adapted to pour a measured quantity. Powder holder 3 is provided for this purpose with a flap 4 with which the pouring opening of powder holder 3 can be closed.

[0029]If a quantity of powder-form zirconium oxide from powder holder 3 is poured, either at one location or spread over the upper surface of the body 2 formed so far, the upper surface is leveled using a driven roller 5 which is coupled to a motor 6. The powder-form zirconium oxide is not only leveled, but also compressed and compacted to the desired extent.

[0030]The installation further comprises a laser generator 7 connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap