Multi-functional tool assembly for processing tool of material processing machine

a technology of material processing machine and tool assembly, which is applied in the direction of cocoa, grain milling, solid separation, etc., can solve the problems of waste reducers being detached from the head, slipping, and slipping, so as to reduce the shear force vector acting on the tool, reduce or redirect the effect of the shear force vector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

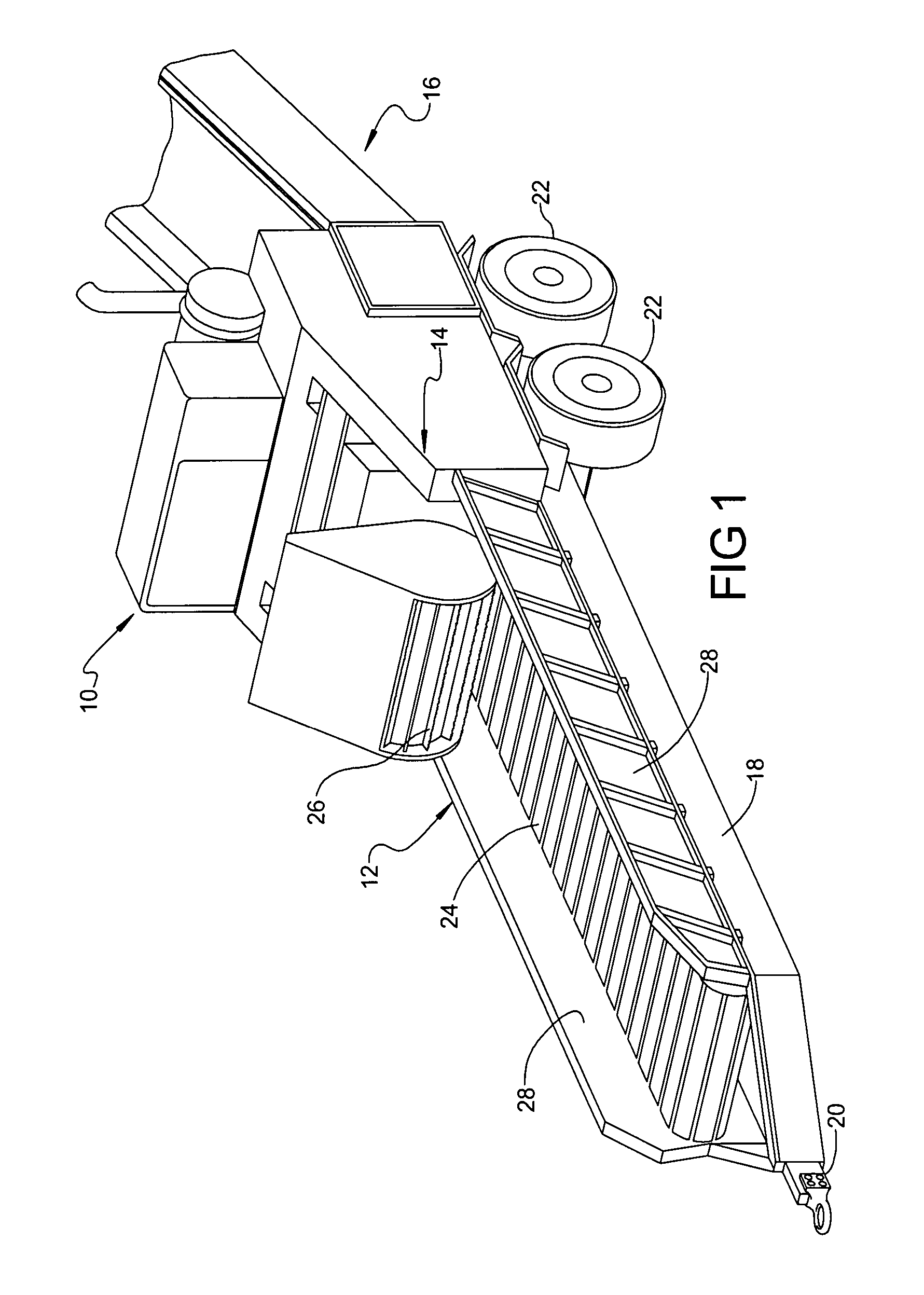

[0022]Referring now to the drawings and in particular to FIG. 1, one embodiment of a material processing machine 10 for reducing material is shown. The material processing machine 10 includes an infeed system 12, a material reducing system 14, and a discharge system 16. Material enters the material processing machine 10 through the infeed system 12 where it is directed to the material reducing system 14. The material reducing system 14 reduces the material and directs it to the discharge system 16 where the reduced material is expelled from the material processing machine 10. The material processing machine 10 may be supported on a trailer framework 18 having a tongue mount 20 provided at a front thereof and wheels 22 near a rear of the framework 18. It should be appreciated that, with this structure, the infeed system 12 and material reducing system 14 can be transported together while the discharge system 16 can be transported separately therefrom. It should also be appreciated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com