Dynamic consolidation of powders using a pulsed energy source

a technology of energy source and powder, applied in the field of powder metallurgy, can solve the problems of high cost of powder metallurgy technology competing with other low-cost manufacturing methods, affecting the efficiency of powder processing, and affecting the quality of powder processing, so as to achieve cost-effectiveness, eliminate combustible gases, and simple adjustment of stored electrical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

16 Ton Press

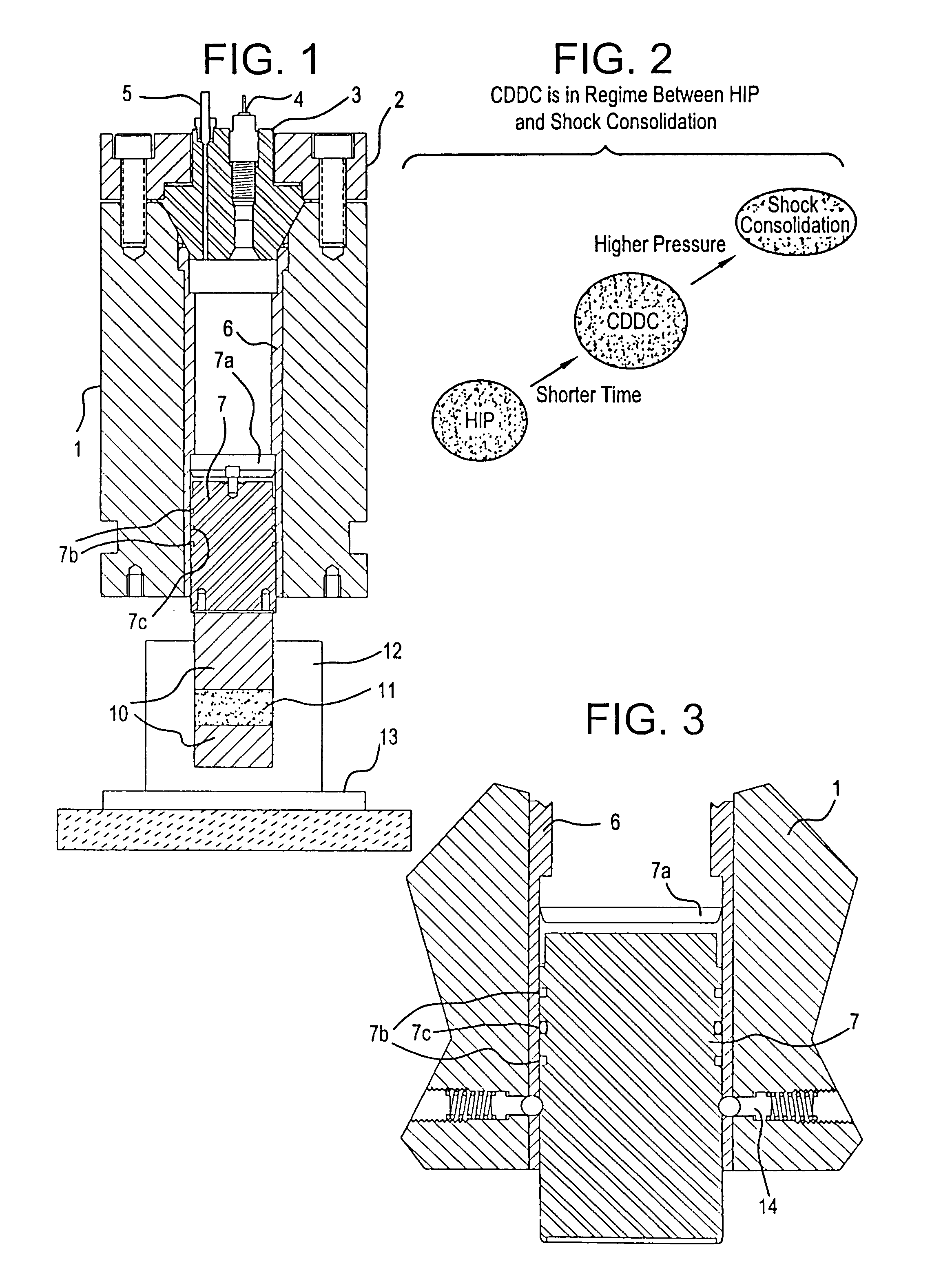

[0214]In initial testing, we completed successful demonstration of the CDDC concept, using the nominal 16-ton device shown in FIG. 7. With this device, we demonstrated consolidation of Al powders (average particle size of 50 to 60 μm) to 97.6% theoretical density. Based on scanning electron microscopy, we found that following powder rearrangement and sliding, plastic deformation resulted in increased contact between the Al powders and in cold welding. The plastic deformation and cold welding contributes to development of the interparticle bonds. The rapid consolidation technique also breaks up the surface oxides and produces local melting at the interparticle contacts giving good interparticle bonding. The compacts were 1.5 cm in diameter and 1 cm long. The total energy used for consolidation in these initial experiments was 133-304 kJ and the resultant peak pressure was in the range 23-47 kpsi. The consolidation was performed at room temperature. The 97.6% theoretical d...

example 2

30 Ton Press

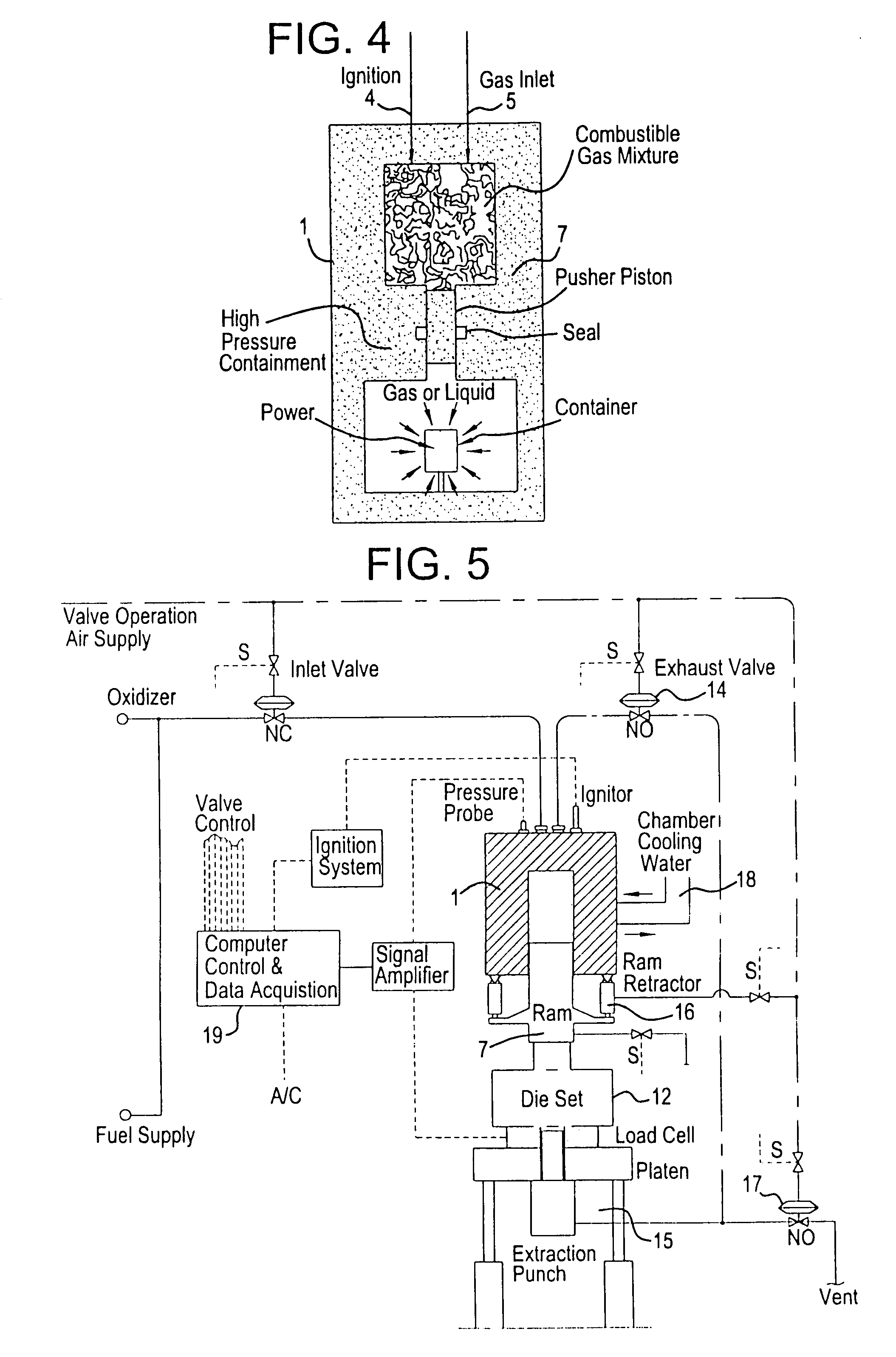

[0221]Testing in the second CDDC prototype, shown in FIG. 19, revealed the CDDC process to be both robust and versatile at compacting various types of powder materials. This larger CDDC device applied up to 300,000 pounds per square inch (150 tons per square inch) to one-half inch outer diameter, ⅝ inch inner diameter, ring shaped compacts of various materials, as shown in Table 3. FIG. 20a shows the same device with a volume filler_ to change the volume of the combustible gas. FIGS. 20b, c and d show additional detail of the compaction chamber, seals, ignitor, and pressure sensor. FIG. 21 shows photographs of two views of the hardware.

[0222]Typical ring compacts are shown in FIGS. 22 and 23. The compaction chamber configuration and the ring die set are shown in FIG. 24. Typical combustion and compaction pressures along with densities and mechanical properties for stainless steel powders compacted by the enhanced CDDC press are shown in FIG. 25. Properties for one of the...

example 3

300 Ton Press

[0224]A third and larger prototype CDDC press further shows the versatility and performance capability of CDDC presses and technology. The internal details of this press were shown previously in FIG. 1. Externally the press looks as shown in FIGS. 29a and 30a, b, and c. Shown there also is the steel framework which supports the compaction unit above the die table. To the left is the cabinet containing the gas pumping system.

[0225]This 300-ton press has compacted standard Metal Powder Industries Federation (MPIF) standard 10 tensile test bars of various materials at pressures exceeding 300,000 pounds per square inch (150 tons per square inch). A typical test bar of 1 square inch surface is shown in two views in FIG. 31.

[0226]As seen in FIG. 1 the 300-ton CDDC press is mounted in the more traditional vertical orientation and uses standardized die sets placed under the press on the incorporated table. The sealing system for the ram has also been substantially improved as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com