Projection system, projection lens module, optical actuator and its driving method

a projection lens and actuator technology, applied in the direction of instruments, printers, cameras, etc., can solve the problems of inability to commercialize the transmissive optical actuator under spatial limitations, and the need for feedback control, so as to reduce residual vibration, reduce driving force, and enhance the performance of the optical actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

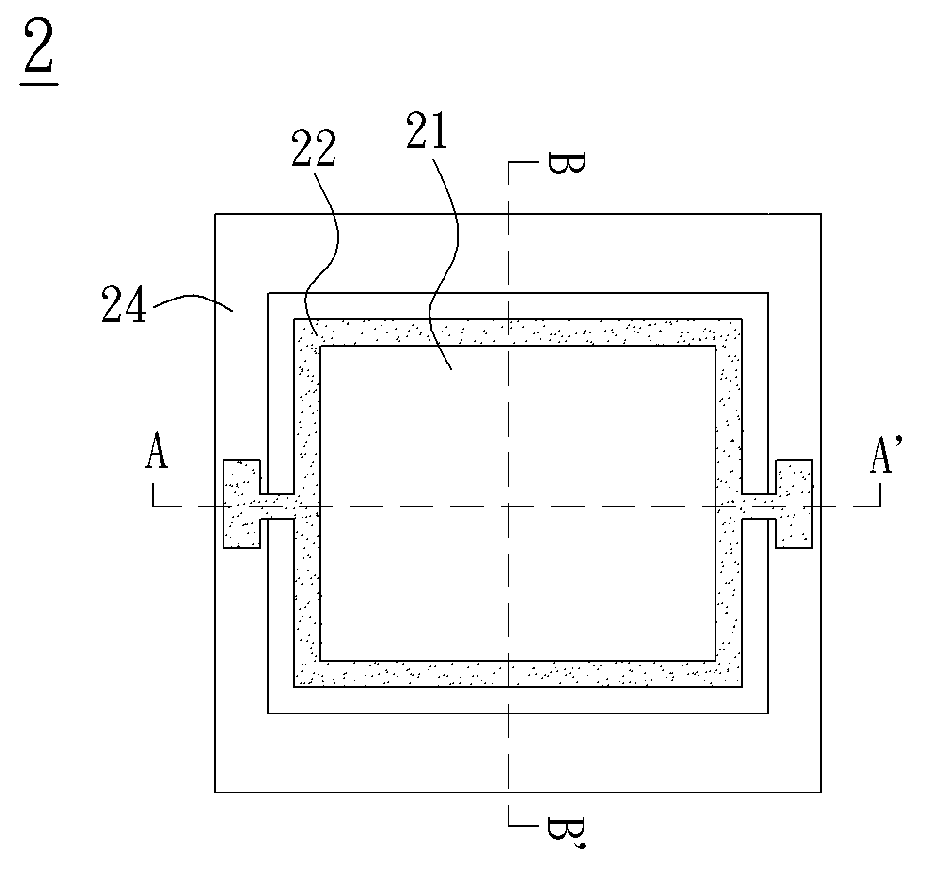

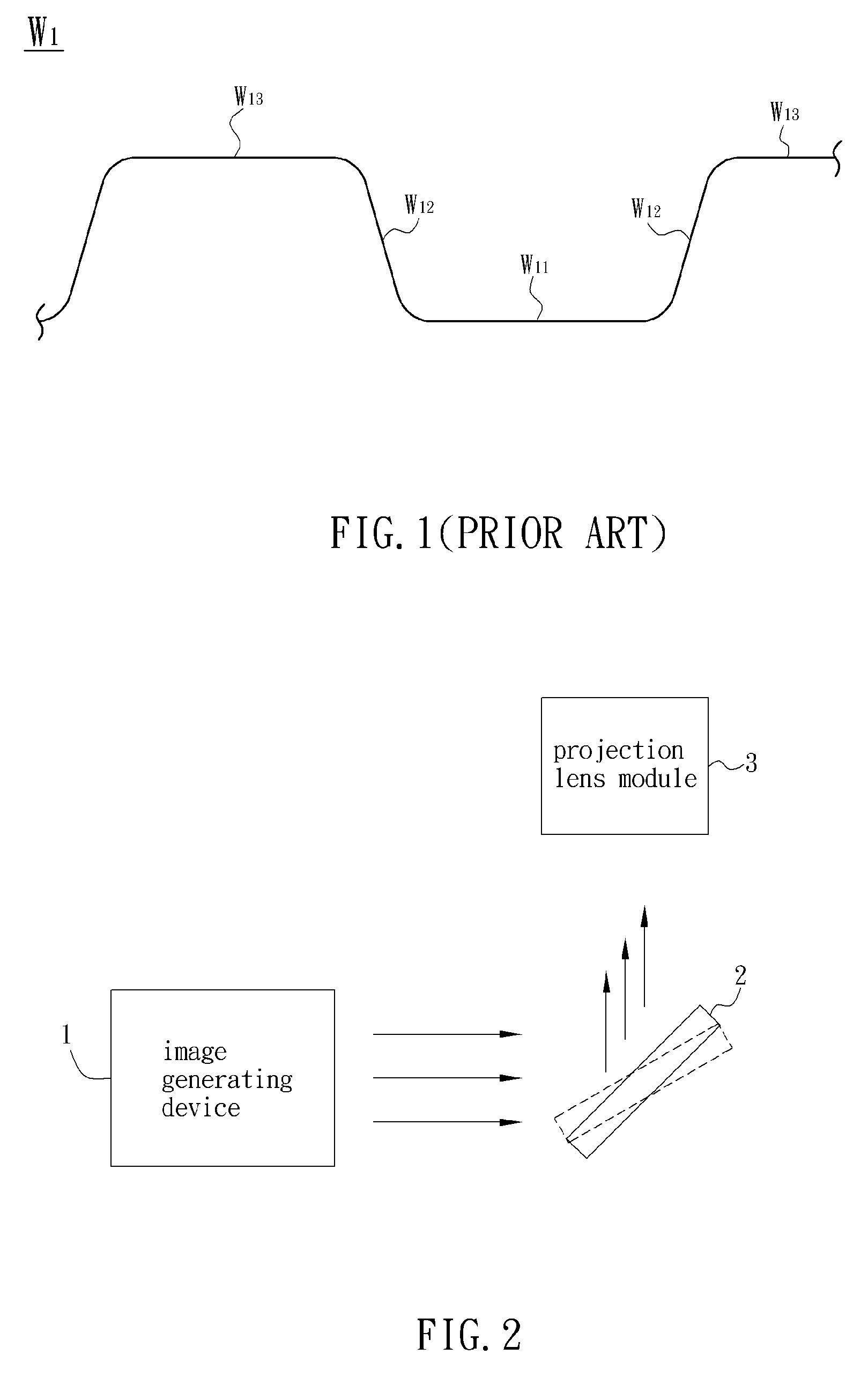

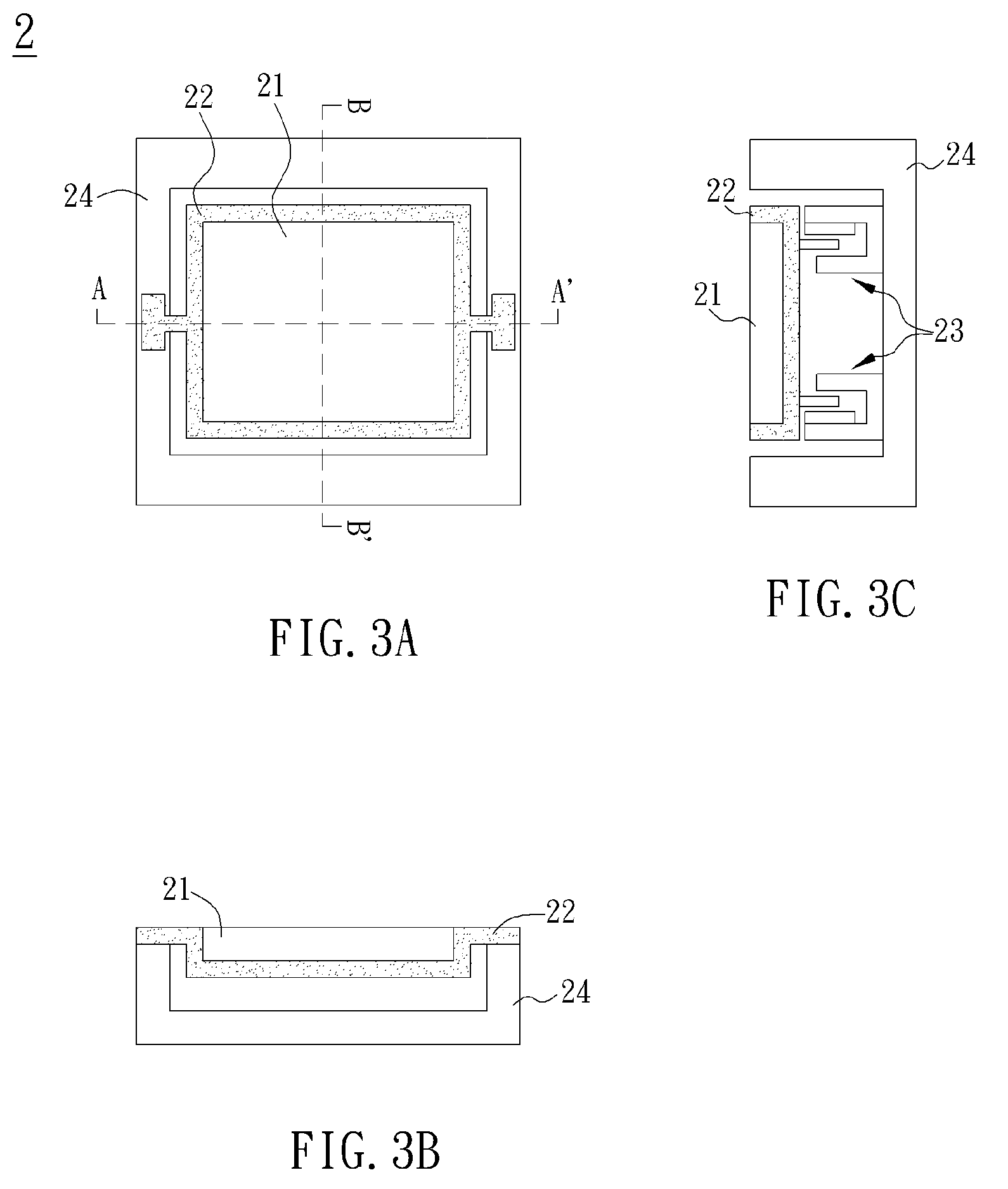

A driving method of an optical actuator according to the embodiment of the present invention can be applied to a projection system such as a front projection system or a rear projection system. Referring to FIG. 2, the projection system includes an image generating device 1, an optical actuator 2 and a projection lens module 3. Herein, the optical actuator 2 is a reflective optical actuator, for example.

The image generating device 1 generates an image according to the DMD, 3LCD panels or LCoS panel technology, which is frequently used in the industry. The projection lens module 3 projects the image onto a screen. The optical actuator 2 can swing repeatedly so that the image can be reflected to at least two positions via the optical actuator 2 and enter the projection lens module 3. Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com